EN

Language

All categories

Product ID: 63684434

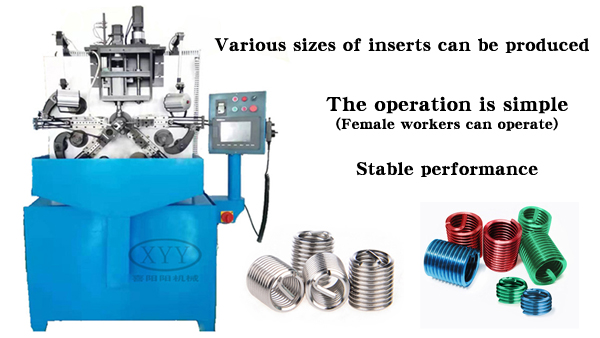

New Automatic Wire Thread Insert Production Line Efficient Metal Winding Machine Equipment

Contact Now

Description

Product Description

Xinxiang Xiyangyang Screening Machinery Manufacturing Co., Ltd. independently developed a new type of fully automatic sleeve winding machine based on years of experience in the production of steel wire sleeves and the actual production habits of users. The equipment is specially used to produce steel wire thread inserts, which meets the technical conditions of the national military standard gjb119.1-4-86 ordinary steel wire thread inserts.

Detailed Images

Working principle of automatic wrapping machine

According to the specifications of the wound steel wire screw sleeve, select the matching front guide nozzle, wire feeding wheel, middle guide plate, wire guide tube and wire guide nozzle (they are all engraved with diamond slots of corresponding specifications), and install them in their respective positions. The diamond shaped steel wire is led out from the pay off frame, straightened by the straightening mechanism, wound through the wire guide nozzle through the wire board, wire feed wheel and wire guide tube.

After one circle of winding, the grooving is carried out. After the grooving is successful, the processing starts again. After winding to the set number of turns, the winding motor starts to reverse and exit the mandrel. The wire feeding motor reverses, so that the tail handle of the steel wire threaded sleeve returns to the outlet of the wire guide nozzle, and the cutting knife cuts forward. At this time, the complete winding process of a screw sleeve is completed.

The equipment has three gears: inching, manual and automatic. After the equipment is debugged, the program can be stored in the computer. During automatic operation, the cam motor and lifting motor must be zeroed first, and then the steel wire threaded sleeve can be wound automatically.

Xiyangyang full-automatic spooling machine supports 24-hour operation and has stable performance. It replaces small lathes and semi-automatic spooling machines. It is a technological innovation and the gospel of the steel wire thread industry.

Product Presentation

A. Overcome the difficult problem of processing small-size steel wire thread inserts, and take the lead in all domestic small-size steel wire thread insert production equipment. B. When adjusting the steel wire thread bushing mandrel, you can directly input the digital control, and the accuracy is more accurate. C. The length of the number of steel wire thread ferrules is expressed in digital form, which is convenient to set and does not need to be calculated. D. After the wire thread is used up, it will stop automatically to ensure that the last piece is authentic. E. The whole machine is electrically controlled and can run continuously for 24 hours. (the pneumatic winder needs to be observed all the time)

Product Name | Automatic wrapping machine |

Characteristic | Stable performance and simple operation |

Power | 380V |

Weight | 850kg |

Production efficiency | Adjustable |

Service | Free training of technicians |

Certificate

Related Products

Company Introduction

Xinxiang Xiyangyang Screening Machinery Manufacturing Co., Ltd. is an innovative private

enterprise integrating technology research and development, processing and manufacturing and trade services. The company mainly manufactures and sells fasteners such as steel wire sleeve, self-tapping screw sleeve, tailless screw sleeve and matching cutting edge measuring tools; the company has technological development strength, a variety of production equipment and high-precision testing equipment, and specializes in providing customers with the design and use of fastener products such as steel wire sleeve, self-tapping screw sleeve and the whole process of technology. Operative support.

Xinxiang Xiyangyang steel wire screw sleeve is widely used in new energy industry. In response to market needs, special plated isolation screw sleeve, silver plated screw sleeve, taper screw sleeve, high temperature resistant steel wire screw sleeve, tin bronze steel wire screw sleeve and GJB steel wire screw sleeve are introduced to meet the needs of different users.

Our company has a perfect quality assurance system and has passed the high standard quality inspection and approval of all partners. In order to open up the market and realize mutual benefit, we will serve our customers wholeheartedly with the win-win business philosophy of "price, quality" and "integrity, service". In line with the principle of "the lowest price, but the best quality", our company wholeheartedly provides high-quality products and honest service for domestic and foreign users.

Xiyangyangyang Steel Wire Sleeve escorts your threads so that tightening is everywhere!

enterprise integrating technology research and development, processing and manufacturing and trade services. The company mainly manufactures and sells fasteners such as steel wire sleeve, self-tapping screw sleeve, tailless screw sleeve and matching cutting edge measuring tools; the company has technological development strength, a variety of production equipment and high-precision testing equipment, and specializes in providing customers with the design and use of fastener products such as steel wire sleeve, self-tapping screw sleeve and the whole process of technology. Operative support.

Xinxiang Xiyangyang steel wire screw sleeve is widely used in new energy industry. In response to market needs, special plated isolation screw sleeve, silver plated screw sleeve, taper screw sleeve, high temperature resistant steel wire screw sleeve, tin bronze steel wire screw sleeve and GJB steel wire screw sleeve are introduced to meet the needs of different users.

Our company has a perfect quality assurance system and has passed the high standard quality inspection and approval of all partners. In order to open up the market and realize mutual benefit, we will serve our customers wholeheartedly with the win-win business philosophy of "price, quality" and "integrity, service". In line with the principle of "the lowest price, but the best quality", our company wholeheartedly provides high-quality products and honest service for domestic and foreign users.

Xiyangyangyang Steel Wire Sleeve escorts your threads so that tightening is everywhere!

Sales network

FAQ

1. Who are we?

We are based in Henan, China, start from 2014,sell to Eastern Europe(10.00%),South America(10.00%),North America(10.00%),Africa(5.00%). There are total about 11-50 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Wire thread insert,Self tapping insert,Tanglees,Keensert,Thread repair kit

4. Why should you buy from us not from other suppliers?

Our company is a professional manufacturer of thread inserts and tools. Xinxiang, a powerful industrial city in Central China,has been engaged in thread nesting industry for more than 20 years.

5. What services can we provide?

Accepted Delivery Terms: FOB,EXW,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English,Chinese

We are based in Henan, China, start from 2014,sell to Eastern Europe(10.00%),South America(10.00%),North America(10.00%),Africa(5.00%). There are total about 11-50 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Wire thread insert,Self tapping insert,Tanglees,Keensert,Thread repair kit

4. Why should you buy from us not from other suppliers?

Our company is a professional manufacturer of thread inserts and tools. Xinxiang, a powerful industrial city in Central China,has been engaged in thread nesting industry for more than 20 years.

5. What services can we provide?

Accepted Delivery Terms: FOB,EXW,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English,Chinese

Contact Now

Please Send Message

${currentPro.title}