High-Speed M4*0.7 Spiral Taps HSS Top Wire Die Tin Coated Flute Tap for Machine for Thread Cutting

Description

wire thread insert m4*0.7 top

| Place of Origin | Henan, China |

| Brand Name | xiyangyangjixie |

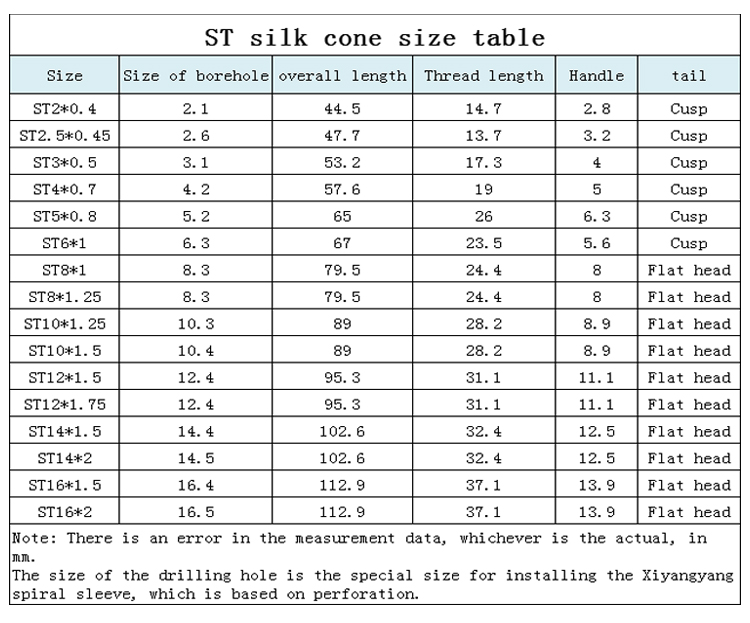

| Model Number | ST4*0.7 |

| Type | Tap |

| Number of Pieces | 1 |

| Material | HSS, Alloy Steel |

| Standard | ISO |

| Size | M4*0.7 |

| Thread Type | Metric/UNC/UNF |

| Flute Type | Straight Flute, Spiral Flute |

| Shank Type | Cusp |

| Application | Tapping of Steel Wire Screw Sleeve |

| Supply Ability | 100000 Piece/Pieces per Month Tap and Die |

| Packaging & Delivery | Packaging Details10 pieces packed in a paper box |

| Port | Shanghai/Ningbo |

Xiyangyang Steel Wire Screw Sleeve Tap is used to process blind hole bottom hole. It can produce chips quickly and has high precision. It can process the bottom hole.

Xiyangyang Steel Wire Screw Sleeve Tap is used to process blind hole bottom hole. It can produce chips quickly and has high precision. It can process the bottom hole.

How to choose screw socket tap?

1. The pitch of a single tap is less than 2 mm, and the pitch greater than or equal to 2 mm is a double tap.

2. Straight groove tap has strong versatility, through hole or blind hole, non-ferrous metal or ferrous metal can be used, the price is cheap, and the quality is medium.

3. Spiral groove tap is more suitable for processing blind hole threads. Chips are discharged backwards during processing. When processing ferrous metals, the helix angle is chosen a little less, generally about 30 degrees, which can ensure the strength of helical teeth. In the processing of non-ferrous metals, the helix angle is chosen less and larger, generally around 45 degrees, so that cutting can be sharper.

${currentPro.title}