EN

Language

All categories

Product ID: 63684661

Wholesale Spark Plugs Wire Thread Inserts for Car and Motorcycle Motor Essential Component

Contact Now

Description

Product Overview

Spark plug insert

Spark plug is a gasoline engine ignition system to introduce high voltage current into the cylinder to generate electric sparks to ignite combustible gas mixture components. It is mainly composed of a wiring nut, an insulator, a wiring screw, a center electrode, a side electrode and a shell, and the side electrode is welded on the shell.

According to the electrode material, can be divided into nickel alloy, silver alloy and platinum alloy.

FEATURES AT A GLANCE

spark plugs for car

spark plugs for motorcycle

PRODUCT SPECIFICATIONS

No | Item | Data | ||

1 | material | ZINC, Stainless steel | ||

2 | Size | m14*1.25-m16*1.25-17mm | ||

3 | Place of Origin | Henan, China | ||

4 | Brand Name | xiyangyangjixie | ||

5 | Model Number | m14*1.25-m16*1.25-7mm | ||

6 | Material | Spark Plugs Repair Insert | ||

7 | Product name | wire threaded insert | ||

8 | Sample | Freely Supplied |

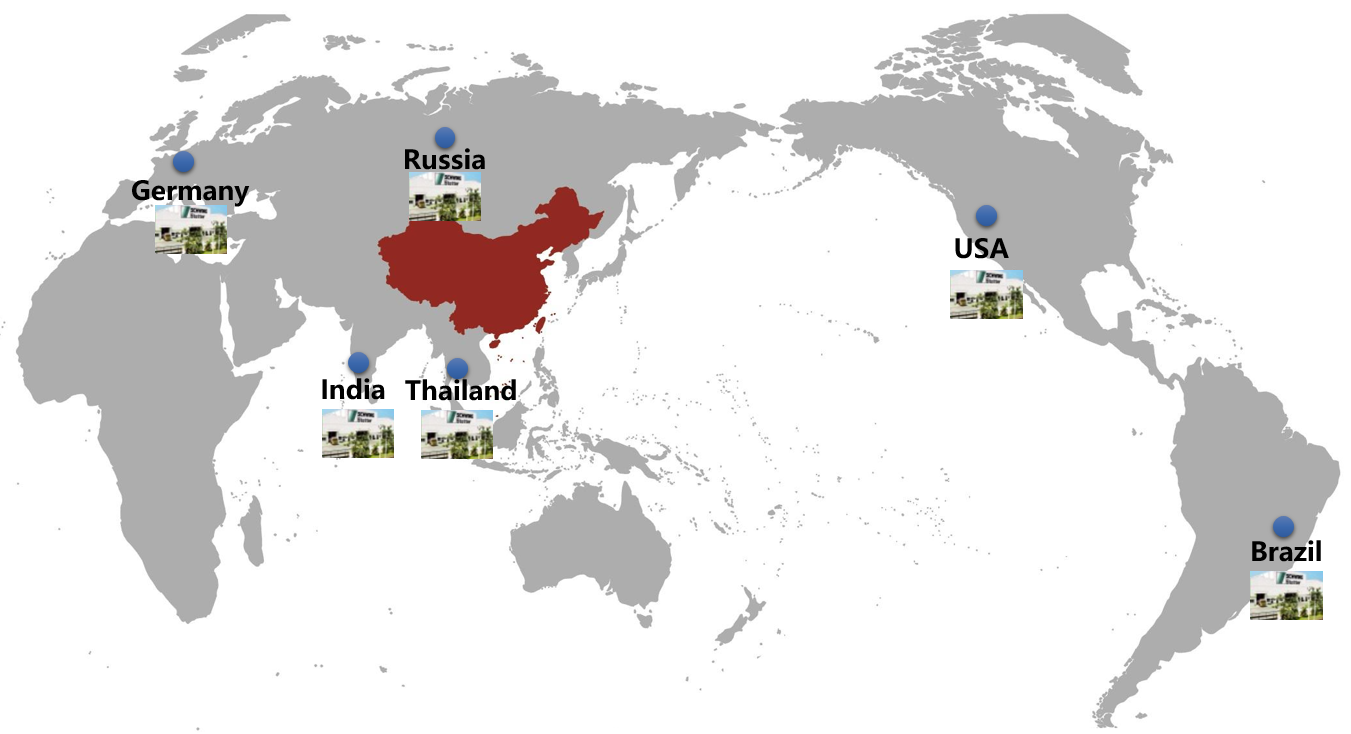

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

Q1:Classification of wire screw sleeves

A1:Classification of wire screw sleeve:

1, according to the use of function classification

A, common type of threaded Inserts (Helicoil Free-Running Inserts) marked "FR"

B, locking Screw Lock Inserts (Helicoil Screw Lock Inserts) marked "SL"

2, according to the steel wire screw sleeve material classification

A, Cr-Ni stainless steel material: through the combination of strength and material, it is usually used in light micro-structure, aluminum alloy structure, seawater, chlorine-containing liquid, and increased corrosion resistance.

B, copper alloy material: in the case of requiring copper or often adjust the rotation of the threaded connection used; Use when required in situations such as conducting electricity or self-lubricating.

C, superalloy material: temperature at 500-750 ℃ heat resistant use; It is used for aerospace assembly technology, aircraft engines and internal combustion engine turbine compressors operating at 750 ° C.

3. Classified according to the type of internal thread formed

A, international standard ISO "M,MJ" series wire screw sleeve

Thread series marked "M", "MJ"; Spark plug Thread (Spark plug Thread) wire sleeve in this series

B, UNIFIED Thread "UN" Series wire sleeve (UNIFIED Thread Series)

Coarse thread marked "UNC", fine thread marked "UNF", ultra-fine thread marked "UNEF"

C, non-thread sealed Pipe Thread (British Standard Pipe Thread) thread mark number is "G"

4, according to the rotation direction of the wire screw sleeve classification

A, right-hand wire screw sleeve

B, left-handed wire screw sleeve

5, according to the steel wire screw sleeve installation handle classification

A, there is a mounting handle wire screw sleeve

B, no mounting handle wire screw sleeve

6, according to the steel wire screw sleeve coating classification

A, no surface treatment layer wire screw sleeve

B, there is a surface treatment layer of steel wire screw sleeve such as: silver plating, cadmium plating, coloring, oxidation, etc.

Contact Now

Please Send Message

${currentPro.title}