EN

Language

All categories

Product ID: 63684891

18-8 High Strength Stainless Steel 304 Four Key Locking Heavy Type 3/8 Inch Thread Insert for Wire Product Genre

Contact Now

Description

Product Description

Specification

item | value |

Application | General Industry, Heavy Industry |

Thread inserts type | Metric thread inserts |

Customized support | OEM, ODM |

Material | Stainless Steel |

Product name | 304 Stainless Steel for Screw Thread Insert |

Size | M1.4-M60 |

MOQ | 100 |

Packing | Small Packing+Carton Packing+Pallet |

Company Profile

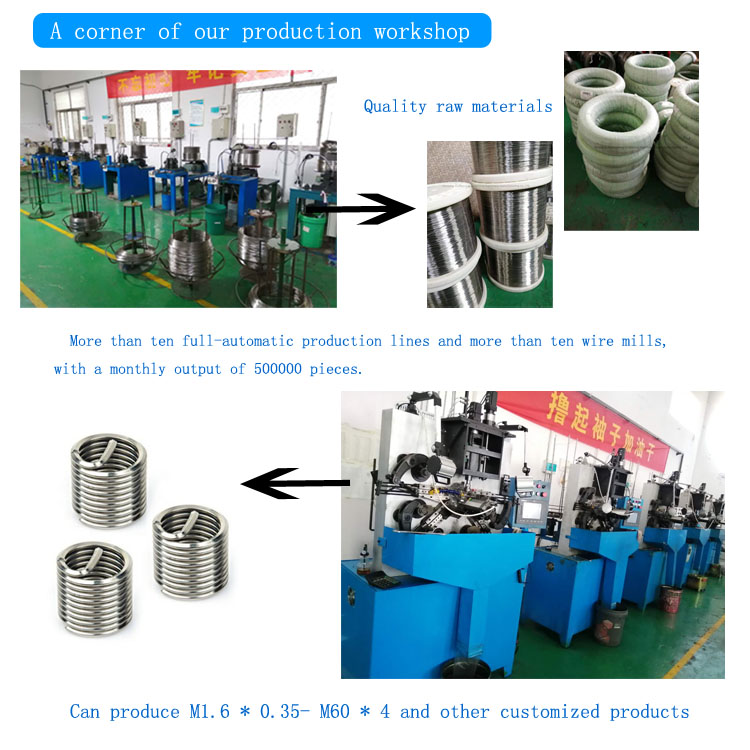

Xinxiang Xiyangyang Screening Machinery Manufacturing Co., Ltd. is a professional design, research and development and production of thread inserts and tools of professional manufacturers. We produce customized thread inserts, self tapping inserts, tailless nesting, keensert and installation tools for inserts. We have also passed the GB / T 19001-2016 / iso9001:2015 standard and GJB 9001c-2017 standard certification, and have relevant SGS certification. Our company is located in Xinxiang, a powerful industrial city in Central China, engaged in thread nesting industry for more than 20 years. Our thread accuracy can reach 5h, our products have been approved by all customers after being put into the market. Our factory has advanced production and testing equipment, automatic CNC production equipment, universal tool microscope, thread grinder and so on. Our company is committed to honesty and innovation, determined to become a world-class steel wire insert brand. Our slogan is "win the future with integrity and quality"

Company introduction

Company profile

Xinxiang Xiyang Screening Machinery

Manufacturing Co., Ltd. aims at "screening particles to the end, so that there is no threaded hole of sliding wire in the world".

We sincerely welcome people of insight from all walks of life to go hand in hand, win-win cooperation and become a long-term

partner!

Manufacturing Co., Ltd. aims at "screening particles to the end, so that there is no threaded hole of sliding wire in the world".

We sincerely welcome people of insight from all walks of life to go hand in hand, win-win cooperation and become a long-term

partner!

Product Description

A lightweight dowel nut is a specialty fastener with an internal and external double threaded configuration with at least two dowel keys on the external threads, often used to reinforce or repair internal threaded holes, especially where there is a need to increase the strength of the connection, prevent thread damage, resist vibration, or resist high loads. The lighter weight of lightweight pin nuts compared to heavyweight pin nuts makes them more suitable for design needs to strengthen thin-walled materials or reduce weight under limited loads.

Heavy Duty Pin Sleeves are a type of high-strength threaded fastener specifically designed to strengthen and repair internally threaded holes in various types of machinery, equipment, structural components, etc., as well as to create high-strength threaded connections in low-strength materials. Heavy-duty pin bushings are typically made of high-strength materials such as high-quality stainless steel or carbon steel, and feature a double-threaded inner and outer structure with a fixed pin key on the outer threads to ensure that the bushings will not loosen or fall off as the threads rotate after installation.

Packaging & Transportation.

Our Certificate and Exhibition

FAQ

Q1: What is a Pin Screw Sleeve?

A1: A pin bushing is a high-strength fastener that is made of wire wound with dual internal and external threads. The outer thread is designed to screw into a pre-tapped hole, while the inner thread fits a bolt or screw. The special feature is that there are at least two pin keys on the external threads, which are pressed into the base material with a special tool after installation, thus preventing the sleeve from rotating or withdrawing under stress and providing strong resistance to pullout and vibration.

Q2: What are the application areas of the pin sleeve?

A2: Pinscrews are widely used in aerospace, automotive, machinery and equipment, railroad transportation, electronics and electricity, etc. Wherever there is a need to enhance the strength of the threaded connection, to prevent the thread from loosening or to repair damaged threads, pinscrews can be used.

Q3: How to install and take out the pin sleeve?

A3: When installing a pin sleeve, first drill and tap a suitable hole in the workpiece, then use a special installation tool to screw the sleeve into the threaded hole, and then use another tool to press the pin key into the predetermined groove in the hole wall to fix it. A special disassembly tool is required to remove the pin sleeve to prevent damage to the sleeve and the workpiece.

Q4: What's the difference between a pinned sleeve and a normal sleeve?

A4: The major difference between a pinned sleeve and a normal sleeve is that it has a unique design that prevents the sleeve from loosening, i.e. the pin key. While a normal screw sleeve may loosen gradually due to vibration or other reasons when it is subjected to axial tension, the Pin Sleeve remains stable even under strong vibration or repeated loading due to the presence of the Pin Key.

Q5: What are the common material choices for the Pin Screw Sleeve?

A5: The common materials used in the pin bushing include stainless steel, carbon steel and other high strength alloys. The choice of material is based on the corrosiveness of the application environment, the strength requirements and the operating temperature.

Q6: Why do you use the pin sleeve on low-strength materials?

A6: Installing a pin sleeve on low-strength materials (e.g. aluminum alloys, magnesium alloys, plastics, etc.) can greatly increase the load-bearing capacity of the threaded holes, preventing failure of the connection due to wear of the threads or lack of strength of the material, and thus enhancing the stability and reliability of the entire system.

Contact Now

Please Send Message

${currentPro.title}