Coil Thread Insert Installation Tools Custom Size Steel Stainless Steel Aluminum Zinc Fasteners M6 M8 M10 M5 M12 Threads Carton

Description

coil thread insert Installation Tools

| Product Name | Manual lever for thread insert install |

| Material | 304 stainless steel |

| Standard | ISO |

| Standard | Metric, UNC, UNF |

| Size | ST3*0.5 |

| Quantity | 10 |

| Sample | Welcome |

| Production capacity | 1000 pieces per week |

| Supply Ability: | 1000 pieces per week |

| Place of Origin | Henan, China |

| Used | Install wire screw sleeve |

Xinxiang Xiyangyang Screening Machinery Manufacturing Co., Ltd. is a manufacturer specializing in various specifications of wire screw sleeves and wire screw sleeve installation tools.

Wire threaded socket mounting wrench:

It is used to fit the wire screw into the bottom hole of the base thread. Usually, according to the power source when installing the wire screw sleeve, it is divided into a manual wire screw socket installation wrench, an electric wire screw socket installation wrench and a steam wire screw socket installation wrench. Manually used for installation is not very large, or large amount but not urgent; when electric is used for a large amount of installation; steam is used for installation is particularly large, usually used in the installation of automatic lines.

The following describes the installation process of the manual wire screw socket installation wrench:The following describes the installation process of the manual wire screw socket installation wrench:

Step 1: Exit the mandrel of the socket wrench and place the wire thread insert into the sleeve from the sleeve slot (slot upward).

Step 2: Use your fingers to prevent the threaded nut from moving and insert the mandrel. Use the groove at the end of the mandrel to catch the mounting handle of the wire screw.

Step 3: Rotate the mandrel, screw the wire screw into the guiding thread of the sleeve installation tool, and pre-shrink the end of the wire screw sleeve with the guiding thread so that it is flush with the end face of the guiding thread (do not let the wire threaded sleeve Unscrew from the guide thread).

Step 4: Align the mounting wrench with the wire screw sleeve with the threaded hole of the base and rotate the mandrel in the direction of the thread until the wire screw is screwed into the threaded hole of the base. During the rotation of the mandrel, the torsion force of the wire screw sleeve may be too large. At this time, it is only necessary to rotate the sleeve in the reverse thread direction (the wrench mandrel does not move) to be alleviated.

Step 5: After the wire screw sleeve reaches the required assembly depth, the mandrel can be withdrawn.

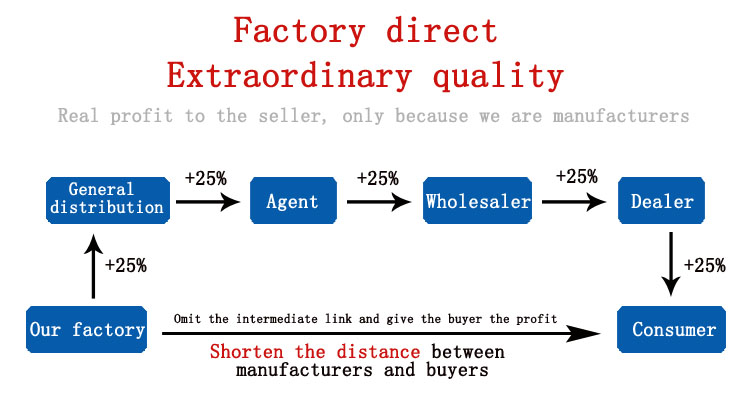

Why choose us?

1. We are a factory, directly facing customers, and the price is advantageous

2. We have been engaged in thread nesting for 20 years and have rich production experience

3. Our company has complete qualifications, military quality and first-class product quality

4. We use high-quality source wire materials, with more than 8 nickel content, and a material report can be provided for each batch

5. Our products have high thread precision (5H), standard teeth, and beautiful appearance

6. Our products are complete in size and support customization

7. Supporting installation tools, one-stop shopping

8. Fast delivery

9. Professional after-sales support to help you solve the problems encountered in installation

10. We are online 24 hours a day, and you are always welcome to consult

If you have another question, pls feel free to contact us as below

${currentPro.title}