5H High-Speed HSS Steel Wire Cone Tap Durable Die for Metric Thread Insert & Thread Cutting

Description

5H High speed steel wire cone for thread insert

| Place of Origin | Henan, China |

| Brand Name | xiyangyangjixie |

| Type | Tap |

| Number of Pieces | 1 |

| Material | HSS, Alloy Steel |

| Standard | ISO |

| Size | All Size |

| Thread Type | 55 Cylindrical Pipe Thread |

| Flute Type | Straight Flute, Spiral Flute |

| Shank Type | Cusp/Square |

| Application | Tapping of Steel Wire Screw Sleeve |

| Supply Ability | 100000 Piece/Pieces per Month Tap and Die |

| Packaging & Delivery | Packaging Details10 pieces packed in a paper box |

| Port | Shanghai/Ningbo |

Xiyangyang Steel Wire Screw Sleeve Tap is used to process blind hole bottom hole. It can produce chips quickly and has high precision. It can process the bottom hole.

How to choose screw socket tap?

1. The pitch of a single tap is less than 2 mm, and the pitch greater than or equal to 2 mm is a double tap.

2. Straight groove tap has strong versatility, through hole or blind hole, non-ferrous metal or ferrous metal can be used, the price is cheap, and the quality is medium.

3. Spiral groove tap is more suitable for processing blind hole threads. Chips are discharged backwards during processing. When processing ferrous metals, the helix angle is chosen a little less, generally about 30 degrees, which can ensure the strength of helical teeth. In the processing of non-ferrous metals, the helix angle is chosen less and larger, generally around 45 degrees, so that cutting can be sharper.

Why choose us?

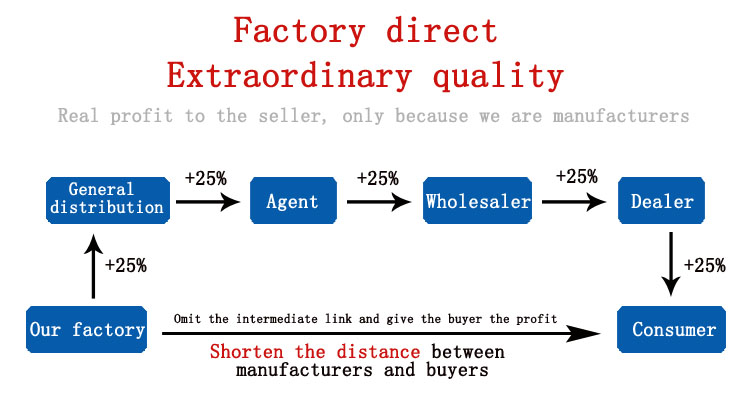

1. We are a factory, directly facing customers, and the price is advantageous

2. We have been engaged in thread nesting for 20 years and have rich production experience

3. Our company has complete qualifications, military quality and first-class product quality

4. We use high-quality source wire materials, with more than 8 nickel content, and a material report can be provided for each batch

5. Our products have high thread precision (5H), standard teeth, and beautiful appearance

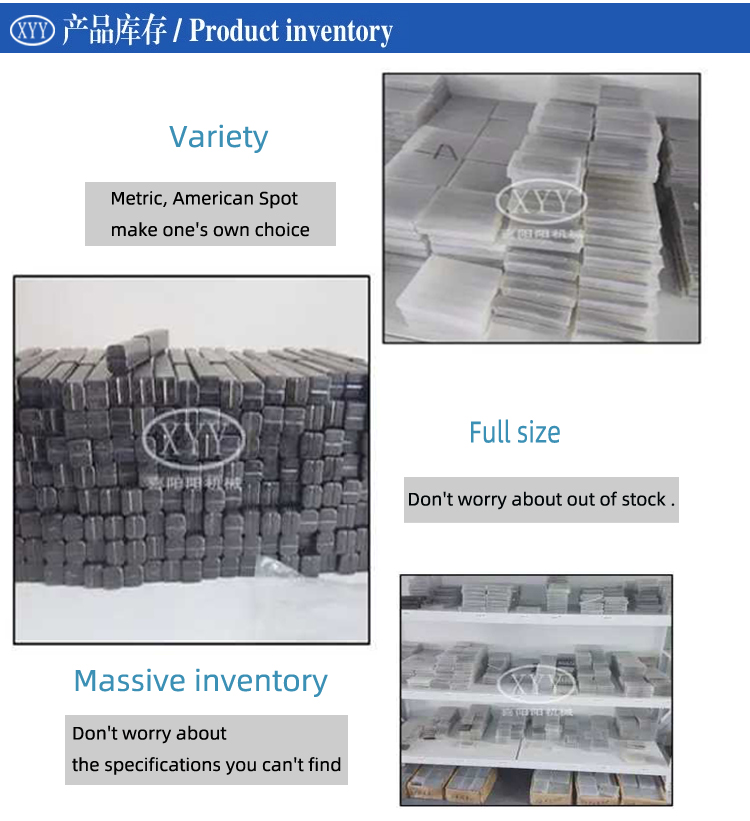

6. Our products are complete in size and support customization

7. Supporting installation tools, one-stop shopping

8. Fast delivery

9. Professional after-sales support to help you solve the problems encountered in installation

10. We are online 24 hours a day, and you are always welcome to consult

${currentPro.title}