EN

Language

All categories

Product ID: 65104946

Keenserts Solid Thread Insert Lock Screws - Metric Zinc and Steel Fasteners

Contact Now

Description

Product Paramenters

Bolt bolt sleeve(thin wall type) specifications | ||||||||

Internal thread | Male thread | Length L (mm) | Drill bit size | Bottom hole depth | ||||

M 2x0.4 | M 4x0.7 | 3 | 3.4 | 4 | ||||

M 2.5x0.45 | M 4.5x0.75 | 3.81 | 3.9 | 5 | ||||

M 3x0.5 | M 5x0.8 | 4.25 | 4.4 | 5.5 | ||||

M 4x0.7 | M 6x0.75 | 5.25 | 5.5 | 6.5 | ||||

M 5x 0.8 | M 8x1.25 | 8 | 6.9 | 9.5 | ||||

M 6x 1.0 | M10x1.25 | 10 | 8.8 | 11.5 | ||||

M 8x1.25 | M12x1.25 | 12 | 10.8 | 13.5 | ||||

M 8x 1.0 | M12x1.25 | 12 | 10.8 | 13.5 | ||||

M10x 1.5 | M14x 1.5 | 14 | 12.8 | 15.5 | ||||

M10x1.25 | M14x 1.5 | 14 | 12.8 | 15.5 | ||||

M12x1.75 | M16x 1.5 | 16 | 14.75 | 17.5 | ||||

M12x1.25 | M16x 1.5 | 16 | 14.75 | 17.5 | ||||

Bolt bolt sleeve (heavy duty) specificatione | ||||||||

Internal thread | Male thread | Length L (mm) | Drill bit size | Bottom hole depth | ||||

M 4x 0.7 | M 8x1.25 | 8 | 6.9 | 9.5 | ||||

M 5x 0.8 | M10x1.25 | 10 | 8.8 | 12.5 | ||||

M 6x 1.0 | M12x1.25 | 12 | 10.8 | 14.5 | ||||

M 8x1.25 | M14x 1.5 | 14 | 12.8 | 16.5 | ||||

M 8x 1.0 | M14x 1.5 | 14 | 12.8 | 16.5 | ||||

M10x 1.5 | M16x 1.5 | 16 | 14.75 | 18.5 | ||||

M10x1.25 | M16x 1.5 | 16 | 14.75 | 18.5 | ||||

M12x1.75 | M18x 1.5 | 18 | 16.75 | 20.5 | ||||

M12x1.25 | M18x1.5 | 18 | 16.75 | 20.5 | ||||

M14x 2.0 | M20x 1.5 | 20 | 18.75 | 22.5 | ||||

M14x 1.5 | M20x 1.5 | 20 | 18.75 | 22.5 | ||||

M16x 2.0 | M22x 1.5 | 22 | 20.5 | 24.5 | ||||

M16x 1.5 | M22x 1.5 | 22 | 20.5 | 24.5 | ||||

M18x 1.5 | M24x 1.5 | 24 | 22.5 | 26.5 | ||||

M20x 2.5 | M30x 2.0 | 30 | 28 | 34.5 | ||||

M20x 1.5 | M30x 2.0 | 30 | 28 | 34.5 | ||||

M22x 1.5 | M32x 2.0 | 32 | 30 | 36.5 | ||||

M24x 3.0 | M33x 2.0 | 33 | 31 | 37.5 | ||||

M24x 2.0 | M33x 2.0 | 33 | 31 | 37.5 | ||||

Details Images

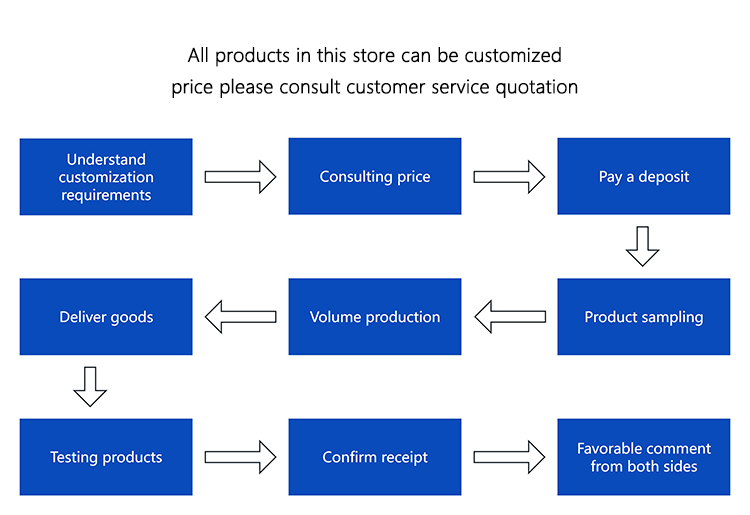

Customized process

Exhibition

1-How do you make sure all the screws pass?

A:We produce mainly 5H precision screw jackets, which are higher than the 6H precision required for inspection, and the production standard is higher than the inspection standard.

2-What is the lead time for the screw bushing?

A:We are a manufacturer, the spot can be delivered on the same day, the slowest is tomorrow's shipment, self-tapping screw set is generally 7 days, self-tapping and pin non-standard products starting quantity is 2000pcs.

3-Why is stainless steel material magnetic?

A:Stainless steel processing deformation process, it will produce weak magnetism is not the material itself has a problem.

4-How do I remove the screw-in sleeve after installation?

A:After the installation of the screw sleeve is not suitable for the specifications can be used to use a special triangular sleeve remover, knocking the tail, then reverse rotation to remove the screw sleeve.

Logistics

Contact Now

Please Send Message

${currentPro.title}