EN

Language

All categories

Product ID: 65270354

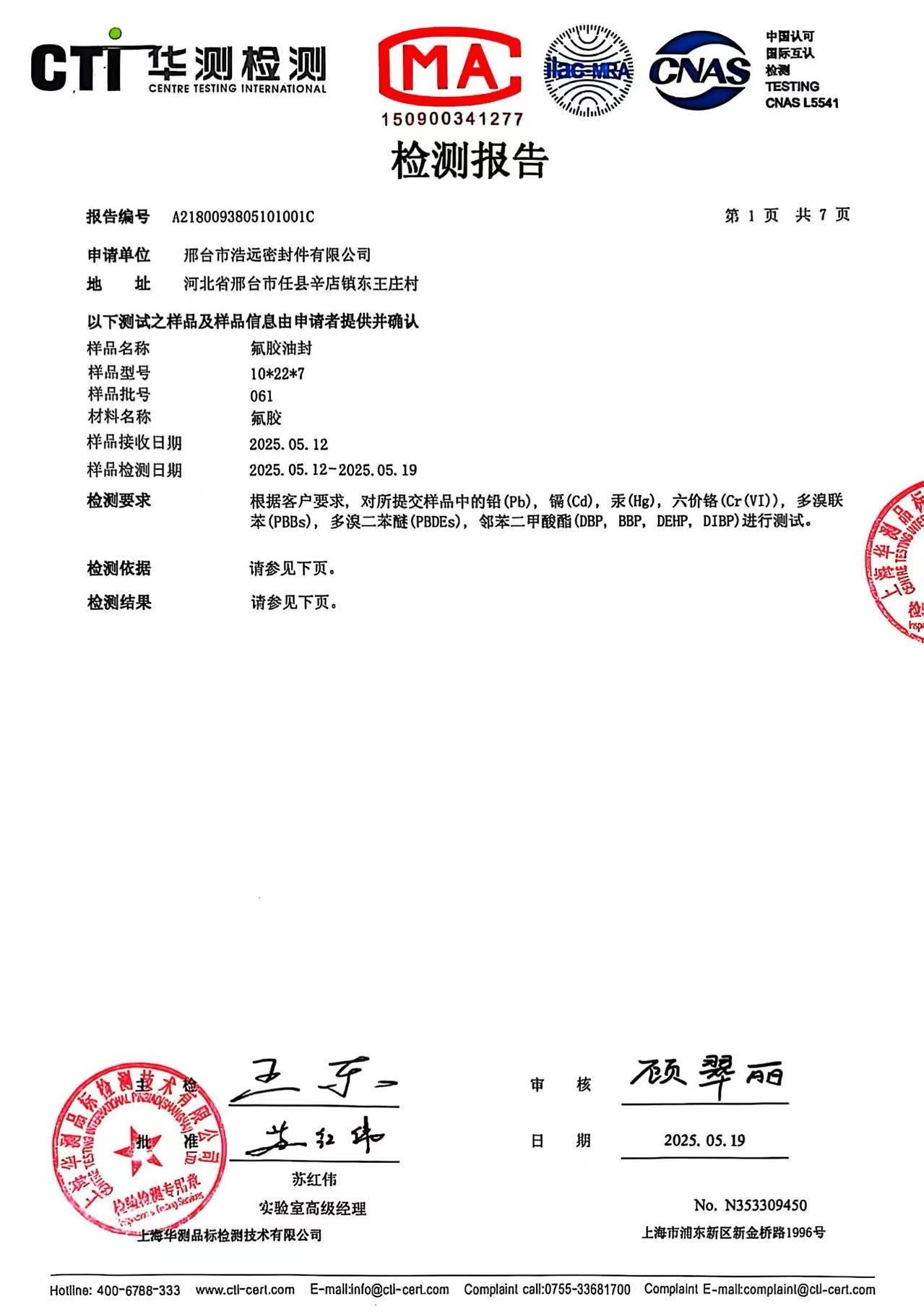

Fluorogar skeleton oil seal

Contact Now

Description

Fluororubber skeleton oil seal, resistant to high temperature 230 degrees, low temperature minus 20 degrees, high wear resistance, particularly good sealing effect, is three times the sealing effect of butadiene rubber oil seal.

The fluororubber skeleton oil seal adopts fluororubber (FKM) as the main sealing material, which has excellent high-temperature resistance. It can operate in high-temperature environments for a long time and has a wide temperature range, up to 200°C or higher. In addition, fluororubber also has excellent chemical resistance and can accommodate a variety of chemical media, including acids, alkalis, solvents, etc. The corrosion resistance of the fluoroethylene skeleton oil seal is also very good, and it can operate stably in various corrosive media.

Fluoride rubber skeleton oil seal has a wide range of uses and is suitable for a variety of industrial fields.

Petrochemical industry: Fluoro rubber skeleton oil seals can be used for pumps, valves, compressors, etc. in petrochemical equipment, and can operate stably in harsh environments such as high temperature, high pressure and corrosive media.

Food processing industry: It is suitable for mixers, conveyors, centrifuges, etc. in food processing equipment to ensure that the product will not be polluted in the process of food processing.

Pharmaceutical industry: used in centrifuges, conveyors, agitators, etc. in pharmaceutical equipment to ensure that drugs will not be polluted in the process of pharmaceutical production.

Aerospace field: Due to its excellent high temperature resistance and chemical resistance, fluoro rubber skeleton oil seals are also suitable for aviation, missiles, rockets and other cutting-edge scientific and technological fields.

In a word, fluorogam skeleton oil seals are widely used in various machinery and equipment with their excellent high temperature resistance, corrosion resistance and chemical resistance, especially in harsh environments such as high temperature, high pressure and corrosive media.

Contact Now

Please Send Message

${currentPro.title}