EN

Language

All categories

Product ID: 66236471

High-Quality Double Offset/Eccentric Butterfly Valves: Customizable Options and Specifications

Contact Now

Description

Product description

|

item

|

valve

|

|

Application

|

Industrial Usage, Water Industrial Usage, Household Usage

|

|

Port Size

|

DN10-DN2000

|

|

Warranty

|

24 month

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Power

|

Pneumatic,Electric,Manual,Hydraulic

|

|

Temperature of Media

|

High Temperature, Low Temperature, Medium Temperature, Normal Temperature

|

|

Brand Name

|

yoonad

|

|

Structure

|

BUTTERFLY

|

|

Media

|

Gas,Water,Oil,Acid

|

|

Customized support

|

OEM, ODM, OBM

|

|

Disc Material

|

Carbon Steel, Stainless Steel, Chrome Molybdenum S

|

|

Seat Material

|

NBR/EPDM/PTFE/Viton/Silicone etc

|

|

Coating

|

Customized

|

|

End Standard

|

Pn6/10/16/25/21/150lb/JIS5K/10K/As2129 Table D/E/F

|

|

Body Material

|

Carbon Steel, Stainless Steel, Chrome Molybdeum St

|

|

Stem Material

|

2Cr13, 1Cr13, Stainless Steel, Chrome Molybdenum S

|

|

Color

|

Customized on Request

|

|

Seal Test Pressure

|

0.66MPa-4.4MPa, 1.1MPa, 1.76MPa, 2.2MPa

|

|

Shell Test Pressure

|

0.9MPa-6.0MPa, 2.4MPa, 3.0MPa

|

|

Transport Package

|

Wooden Case

|

Metal seated butterfly valve is the newly-developed long-life and energy-saving products.

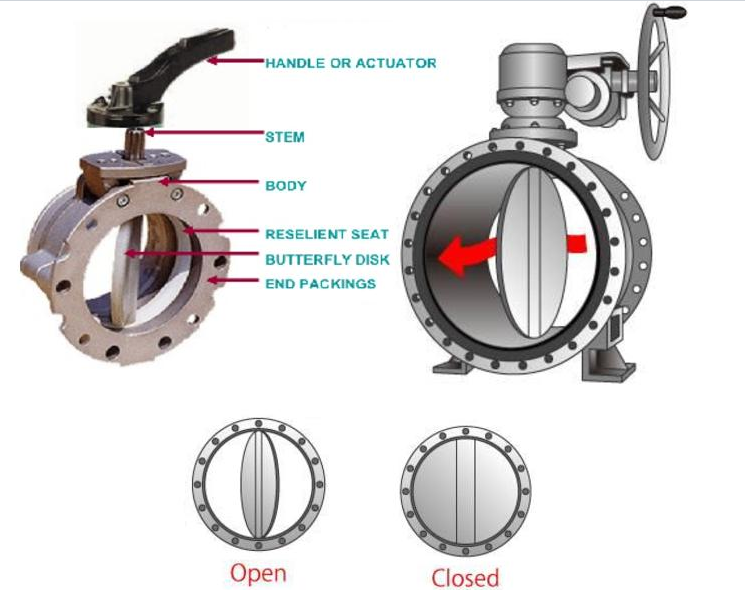

A metal seated butterfly valve is a type of valve which can be used for isolating or regulating flow. The closing mechanism is the disc, which sits in the center of the valve body. The disc is connected to a handle or actuator via the shaft, which passes from the disc through the top of the valve body. Unlike a ball valve, the disc of the butterfly valve is always present in the flow,which will induce a pressure drop.

A metal seated butterfly valve is a type of valve which can be used for isolating or regulating flow. The closing mechanism is the disc, which sits in the center of the valve body. The disc is connected to a handle or actuator via the shaft, which passes from the disc through the top of the valve body. Unlike a ball valve, the disc of the butterfly valve is always present in the flow,which will induce a pressure drop.

• Triple offset geometry

• Integral metal seal ring sealing

• Zero Leakage for both way

• Anti-blow out shaft

• Fire safe design to API607

• Replaceable Seat & Disc Sealing

• 0°-90°control, no jump area

• Friction free

• Integral metal seal ring sealing

• Zero Leakage for both way

• Anti-blow out shaft

• Fire safe design to API607

• Replaceable Seat & Disc Sealing

• 0°-90°control, no jump area

• Friction free

A metal seated butterfly valve operates in a quarter turn style, meaning that rotating the closed disc 90° will fully open the valve, and vice versa. They can also be opened incrementally in order to throttle flow.

A metal seated butterfly valve operates in a quarter turn style, meaning that rotating the closed disc 90° will fully open the valve, and vice versa. They can also be opened incrementally in order to throttle flow. This can be accomplished manually, but throttling flow is more precise when used in conjunction with an actuator. Actuators can be customized to allow incremental flow, by using positioners in the case of pneumatic and hydraulic actuators, or by using modulating boards in the case of electric actuators.

A metal seated butterfly valve operates in a quarter turn style, meaning that rotating the closed disc 90° will fully open the valve, and vice versa. They can also be opened incrementally in order to throttle flow. This can be accomplished manually, but throttling flow is more precise when used in conjunction with an actuator. Actuators can be customized to allow incremental flow, by using positioners in the case of pneumatic and hydraulic actuators, or by using modulating boards in the case of electric actuators.

Applications of Metal Seat Butterfly Valves

Metal Seated Butterfly Valve is widely used in petroleum, natural gas, piped gas and medicine, food industry, industrial environmental water treatment and shipping industry.

Application standardsMetal Seated Butterfly Valve is widely used in petroleum, natural gas, piped gas and medicine, food industry, industrial environmental water treatment and shipping industry.

Valve Marking: MSS-SP-25

Design & Manufacture: API 609, EN 593

Face to Face Dimension: API 609, ISO 5752, EN 558

End Connection: ASME B16.5, ASME B16.47, EN 1092, JIS B2220, GOST 12820

Test and Inspection: API 598, EN 12266, ISO 5208

Contact Now

Please Send Message

${currentPro.title}