EN

Language

All categories

Product ID: 66236927

API Standard Cast Steel High Pressure Flanged Unidirectional Check Valve: A Comprehensive Guide

Contact Now

Description

Product description

|

item

|

valve

|

|

Application

|

Industrial Power Plant Marine Chemical Construct Transport Energy Transport

|

|

Port Size

|

DN10-DN200

|

|

Warranty

|

2 Years

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Model Number

|

CVC003

|

|

Power

|

Automatic

|

|

Temperature of Media

|

High Temperature, Low Temperature, Medium Temperature, Normal Temperature

|

|

Structure

|

Swing, Lift

|

|

Media

|

Oil, Water, Steam, Vapor, LNG, LOX

|

|

Customized support

|

OEM, ODM, OBM

|

|

Design

|

BS 1868 / API 6D / ASME B16.34

|

|

Pressure Rating

|

ASME 150#,300#,600#,900#,1500#, 2500#

|

|

Face to Face

|

ASME B16.10

|

|

Certificates

|

CE/ISO/SGS/Mtc

|

One of the most significant benefits of the high pressure check valve is to prevent water hammering, and it is almost visible or possible in different applications. It protects compressors and pumps from any damage due to water pressure. It causes a low-pressure drop, which can also help to save power or energy.

High pressure check valve reduces or eliminates the chances of sudden valve failure. These valves are flexible, which can facilitate in coping with variable flow conditions. In many applications, it can also be used to reduce downtime. Hence, these benefits can also vary in different applications.

High pressure check valve reduces or eliminates the chances of sudden valve failure. These valves are flexible, which can facilitate in coping with variable flow conditions. In many applications, it can also be used to reduce downtime. Hence, these benefits can also vary in different applications.

Product Applications

* For liquid media (e.g. water, hydraulic oil) in high-pressure applications

* Test benches (e.g. for hydraulic components)

* High-pressure panels

* Wellhead control panels (WHCPs) and hydraulic power units (HPUs)

* Test benches (e.g. for hydraulic components)

* High-pressure panels

* Wellhead control panels (WHCPs) and hydraulic power units (HPUs)

Advantages of Check Valve

-Backflow should be avoided. -Capable of withstanding both high and low pressures. -Ability can be utilized horizontally and vertically as a backup and safety system. -Self-actuated. -Quick to react. -Backflow protection is necessary to avoid damage to pumps and compressors. -Reduce downtime and production losses. -Water hammer can be avoided. -Reduce the likelihood of unexpected valve failure. -Maintenance expenditures are reduced. -There are only a few moving pieces. -A smaller carbon footprint. -Adaptable to varying flow conditions. -Does not need the use of electricity to function.

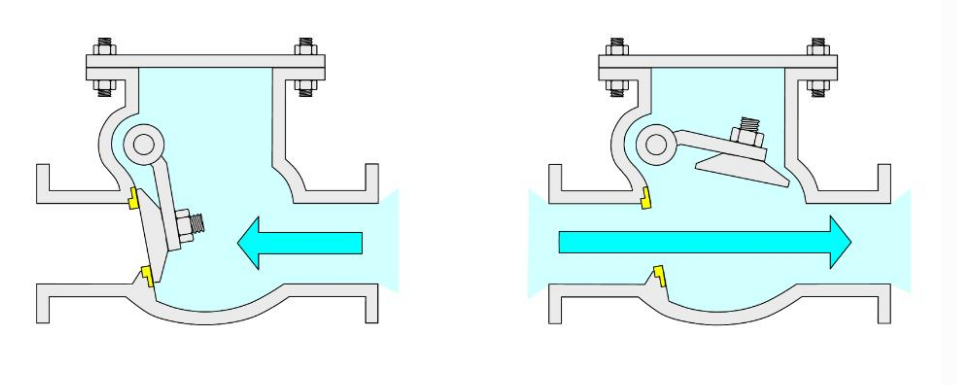

Check valves are commonly installed in systems that can't accommodate backflow as they allow flow in just one direction. It uses a pressure differential to work, that is, the pressure on the inner side is more than the outer side when the valve opening is done. Peradventure, there's insufficient pressure for the inner side, the valve closes. However, they differ from other valves as they operate without handles, actuators, levers, or workforce.

Contact Now

Please Send Message

${currentPro.title}