EN

Language

All categories

Product ID: 66265630

Stainless Steel Vacuum Toilet

Contact Now

Description

Product description

高品质定制不锈钢真空马桶 - 为您的空间带来实用和美丽的享受

不锈钢真空马桶是一种新型的环保洁具,采用优质不锈钢制成,具有耐腐蚀、易清洁、强度高等特点。马桶采用独特的真空技术,通过形成负压并将污垢快速吸入管道中,实现高效排水。真空马桶分为壁挂式真空马桶和壁挂式真空马桶两种,以满足不同用户的需求。

壁排式真空马桶采用隐藏式水箱设计,将水箱安装在墙壁上,节省空间,降低噪音。壁挂式吸尘马桶采用悬挂式设计,底部无支撑,节省空间,易于清洁。此外,我们还提供定制真空马桶服务,根据客户需求,定制不同尺寸、形状和颜色的不锈钢真空马桶,以满足个性化需求。

不锈钢真空马桶的设计特点主要包括以下几个方面:

1、选材:采用优质不锈钢材料,具有耐腐蚀、耐高温、耐磨等特点,确保坐便器的长期使用和稳定性。

2. 真空技术:利用真空原理,通过形成负压,将污垢迅速吸入管道中,实现高效排水。这种设计不仅提高了排水速度,而且有效地防止了管道的堵塞。

3、节水设计:真空马桶在排水过程中由于负压而需要的水较少,从而达到节水的目的。这对于节约水资源非常重要。

4、静音设计:吸尘马桶在排水过程中,由于负压的作用,声音水流小,达到静音的效果。这对于需要安静环境的地方(例如医院和酒店)尤其重要。

5、卫生设计:真空马桶具有更好的密封性能,可有效防止异味的产生,增强卫生环境。同时,不锈钢材料易于清洁,减少了细菌的滋生。

6、空间利用:壁挂式吸尘马桶和壁挂式吸尘马桶均采用节省空间的设计,适用于多种空间布局。尤其是壁挂式真空马桶底部无支撑,更节省空间。

7、定制服务:提供定制真空马桶服务,根据客户需求,定制不同尺寸、形状、颜色的不锈钢真空马桶,满足个性化需求。

8. 安全性:不锈钢真空马桶在设计和制造过程中注重安全性,确保产品在使用过程中不会对用户造成伤害。

9. 环保:吸尘马桶的节水设计和对污垢的有效处理有助于减少对环境的影响,符合现代环保理念。

10、舒适性:真空马桶的设计注重用户体验,如座椅的舒适度、冲水方式的便利性等,为用户提供更舒适的体验。

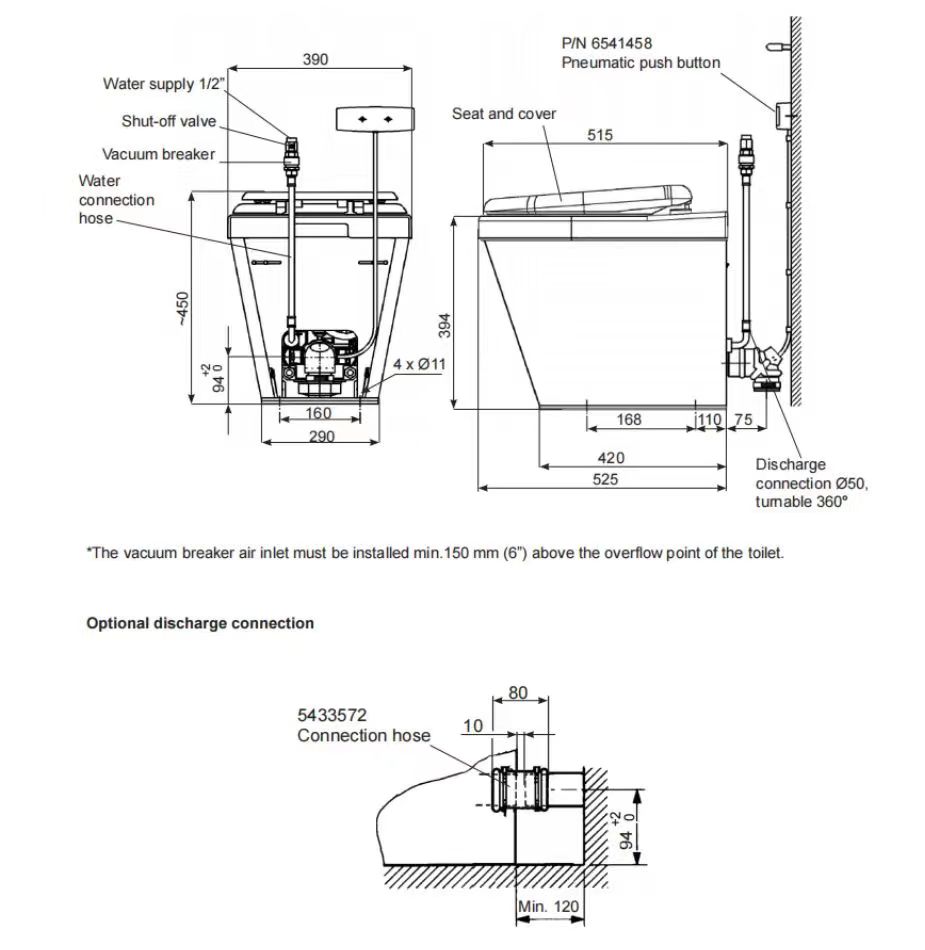

不锈钢真空马桶的组成部分主要包括:

1. 冲水按钮:用于启动冲水过程。

2、供水增压器:提高供水压力,保证冲洗效果。

3. fresh water tank: stores fresh water for flushing.

4. Sewage tank: Temporarily stores sewage after flushing.

5. Drain valve: controls the discharge of sewage.

6. Injector: utilizes the vacuum principle to draw dirt into the pipe.

7. Intermediate tank: intermediate channel connecting each part.

8. Water inlet valve: control the water inlet of fresh water tank.

9. Controller: electronic equipment that controls the whole flushing process.

10. Flushing nozzle: Spray out the fresh water for flushing.

11. vacuum pump: to maintain the vacuum state of the whole system, to ensure the flushing effect.

These components together constitute the complex system of stainless steel vacuum toilet, so that it can complete the flushing process efficiently, water-saving, hygienic .

The manufacturing process of stainless steel vacuum toilet mainly includes the following steps:

1. Material selection: select high quality stainless steel material to ensure that it has good corrosion resistance, high temperature resistance and mechanical properties.

2. Main body manufacturing: the main body of the vacuum toilet is generally made of stainless steel and ceramic materials. The stainless steel part is made through precision machining process, while the ceramic part is made through ceramic process such as grouting, drying and firing.

3. Spray system design: The spray system of vacuum toilet is divided into two types: one-piece ring spray system and split ring spray system. The one-piece annular spray system includes a hose connector and an annular open groove structure, as well as a hose connector and an annular closed groove structure with a water outlet. Split-ring sprinkler systems include pipe fittings and ring sprinkler hose inserts with spray holes.

4. Drainage outlet design: Toilet outlet design has two main types, namely, “zigzag” drainage loop and outlet and rear drainage L-type outlet.

5. Assembly and testing: assembling each component together and conducting strict tests to ensure the functionality and sealing of the toilet.

6. Surface treatment: Polishing and plating the stainless steel surface to enhance aesthetics and durability.

7. Quality Control: Through multiple quality testing sessions, we ensure that our products comply with relevant standards and user requirements.

These steps ensure that the stainless steel vacuum toilet is efficient, water-saving, hygienic and silent.

Stainless steel vacuum toilet has the following advantageous features compared with the traditional toilet:

1. Water saving: The vacuum toilet uses air pressure difference to realize flushing, which can save a lot of water resources compared with the traditional water flushing toilet.

2. Silent: Since flushing does not require a large amount of water flow, it is quieter in use and does not produce greater noise.

3. Hygienic: The flushing method of vacuum toilet can clean the inside of the toilet more thoroughly, reducing the residue of bacteria and dirt.

4. Durable: Stainless steel material has good corrosion resistance and high temperature resistance, longer service life.

5. Aesthetics: Stainless steel has a modern appearance and is easy to clean, which can enhance the overall aesthetics of the bathroom.

6. Comfort: The design of vacuum toilet is usually more humanized, comfortable to sit, better experience.

7. Environmental protection: Due to water conservation, vacuum toilet has less impact on the environment, in line with the modern concept of environmental protection.

8. Strong adaptability: vacuum toilet can be adapted to different water quality and climate conditions, a wide range of uses.

9. Easy maintenance: stainless steel material is not easy to rust, cleaning and maintenance is relatively simple.

10. Energy Saving: Since flushing does not require a large amount of water, energy consumption can be reduced.

These features make stainless steel vacuum toilets increasingly popular in modern homes and public places.

If you are looking for high-quality custom stainless steel vacuum toilets, please contact us immediately. Our custom stainless steel vacuum toilets are carefully manufactured with high-quality 304 or 316 stainless steel materials, with excellent corrosion resistance, strength and aesthetics, ensuring that your products can maintain excellent performance in various usage environments.

We provide a full range of customization services, including customized stainless steel toilets of different sizes, shapes and surface treatments to meet the needs of home, commercial and public occasions. Each custom stainless steel vacuum toilet undergoes rigorous quality testing to ensure its structural stability, excellent water-saving performance and beautiful appearance.

Whether it is a family residence, hotel, hospital, or commercial and public facilities such as shopping malls and office buildings, we can provide you with professional customized solutions and services. Contact us now to experience our high-quality custom stainless steel vacuum toilets, which will bring unprecedented practicality and beauty to your space. Let our products add a sense of quality assurance and trust to your daily life and work environment.

Q1: What metal products does your company mainly produce?

A: Our company specializes in custom stretched metal products, including but not limited to metal tubing, metal rods, and special-shaped materials.

Q2: What is the process for custom products?

A: Customer provides product requirements or drawings -> Technical assessment and quotation -> Order confirmation -> Design and production -> Quality inspection -> Shipment

Q3: How does your company ensure product quality?

A: We have a strict quality management system in place. All products are inspected multiple times during production to ensure they meet national standards and customer requirements.

Q4: What is the typical delivery time for an order?

A: The delivery time depends on the complexity of the product and the order quantity, typically ranging from 15 to 45 working days.

Q5: How can we contact you for custom inquiries?

A: You can reach us by phone, email, or online customer service. We will provide you with prompt service.

Q6: Do your products meet international standards?

A: Our products are produced in strict accordance with international standards and have passed relevant certifications, such as ISO 9001 Quality Management System certification.

Q7: How is logistics and transportation arranged for the products?

答:我们可以根据客户的要求安排物流运输,包括空运、海运或陆运,并确保产品安全准时交付。

Contact Now

Please Send Message

${currentPro.title}