QT4-15 automatic electric concrete block making machine

Description

产品描述

QT4-15 automatic Concrete Interlock Block Brick Making Machine

1. This equipment is mechanical hydraulic PLC controlled synthesis technique equipment. Its characteristic is high efficient, easy-operated, and easy-maintained. Block molding mainly by hydraulic, machinery as a sideline, vibrate, and press to finish molding blocks.

2. The design and manufacture of this solid brick produce line in accordance with the requirement and standard of building.

3. A high degree of automation, intelligent electronic control, the automatic process is controlled by advanced PLC(Programmable Logic Controller), input and store of process data and touch screen for blocks, it has the ideal of flexible Human Conversation Interface.

4. Good reliability, Hydraulic system preference for improved technology and perfected workmanship of design. Use an independent integrated type hydraulic station. Avoid the influence of dust and main machine vibration for the hydraulic system.

5. Good adaptability of raw material, advanced step vibration molding technology. Adjusting measures to differing conditions. Use of all kinds of waste ash and slag, reasonably reduce the dosage of cement, make many kinds of high-quality bearing or non-bearing blocks.

FEATURES

Main Machine

1. This QT4-15 block produce line can use fly ash, slag, gangue, and other kinds of industrial residues then with sand, water, crushed stone, cement all kinds of material to make all kinds of hollow blocks, paver brick, solid bricks just changing the molds. And the percentage of the fly ash can reach 70%.

2. The whole process of this block machine is controlled by PLC and powered by the hydraulic system. Monitoring with the approach switch, machinery, electric, hydraulic and vibrating system work together to make pallets feeding, material feeding, vibrating, the demolding process works automatically. And its characteristic is high efficient, easy-operated and easy-maintained.

Mixing System

The JS series concrete mixer is a double-horizontal-shaft compulsory mixer. This machine has the two advantages of a stand-alone operation and a simple mixing station with the PLD series batching machine. It is a high-efficiency model with a wide range of applications.

Conveyor Belt

The conveyor belt on the brick machine production line can more quickly transport sand, cement and stones to the mixer for mixing, thereby saving labor costs and improving efficiency.

Block Stacker

Automatic Brick Collecting stacker machine System can Collect and stack up produced concrete bricks.meanwhile,it can clean and stack up the pallets. Save 5-6 persons,improve production efficiency.

PLC Control System & Hydraulic System

Control the operation of the brick-making machine: feeding, shaking, pressing, sending, and other operating instructions. Programmable Logic Controller, intelligent control system. There are two modes: automatic mode and manual mode, one-key conversion, the unmanned operation can be realized. Very convenient and easy to operate. The hydraulic station provides power support for the brick machine production line, so that the brick machine can run faster.

Block Mold

The mold of the brick machine is an indispensable part of product production. Used as a model to produce various styles of bricks. The mold uses wire cutting technology to make the mold size more accurate and the cutting surface smoother. Using heat treatment and carburizing technology, the processed mold has higher hardness, more wear resistance, and longer service life.

Our Service

Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

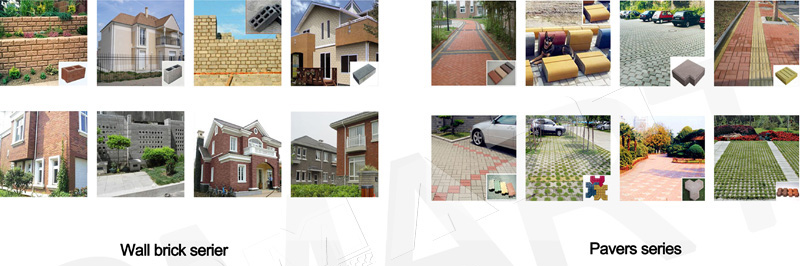

Block Application

Customer Visit

${currentPro.title}