EN

Language

All categories

Product ID: 66684731

Advanced 100 Nm³/h Air Separation Liquid Nitrogen Generator with High Purity for Beverage Industry: Fully Automated Solution for

Contact Now

Description

产品描述

低温氧气 氮气 氩气生产装置 氧气 液体制造

空分装置液氧氮发生器厂

Advanced Air Separator Filter 100Nm3/H Fully Automatic High Purity Liquid Nitrogen Generator For Beverage

产品简介

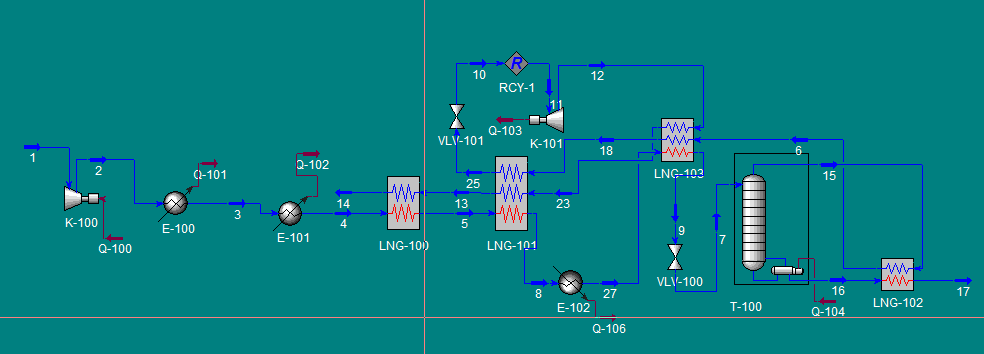

工作原理:

空分装置是从空气中提取液氮的一套深层冷冻方法。该工艺采用

低压涡轮膨胀机的深冻循环原理,使空气变为液态。然后,根据液氧和液氮的沸点,在分馏塔中对空气进行精馏,得到99.99%以上的液氮。

低压涡轮膨胀机的深冻循环原理,使空气变为液态。然后,根据液氧和液氮的沸点,在分馏塔中对空气进行精馏,得到99.99%以上的液氮。

Process description:

The air passes through the air filter, enters the air compressor, compresses to 0.7mpa in the compressor, and then enters the purifier after cooling, where the impurities such as water, carbon dioxide and acetylene in the air are removed. The purified air enters the heat exchanger for heat exchange with the backflow polluted nitrogen. A part of the gas is pumped into the turbine expander through the outlet of the heat exchanger, and the expansion provides a cooling source for the whole set of devices. The other gases continue to cool through the second heat exchanger and then enter the rectifying tower, where they are separated by oxygen and nitrogen. Finally, qualified liquid nitrogen is obtained from the top of the rectifying tower. After decompression by the throttle valve, the liquid air at the bottom enters the condensing evaporator at the top of the tower and the nitrogen heat exchange at the top of the rectifying tower, and then passes through the cooler, the second heat exchanger and the main heat exchanger cooling box as the regenerative purifier.

Equipment advantages:

1. The overall skid-mounted direct connection structure and high pressure hose connection make it unnecessary for users to invest in connecting pipelines and valves between devices, saving your investment cost.

2. The user only needs to make the equipment workshop and the ground and lifting tools in the workshop, without preparing other installation materials and tools.

3. Small size and low footprint.

4. The whole set of equipment has no foundation installation, stable operation, simple operation and convenient maintenance.

5. Since the equipment adopts internal compression process, the maintenance cost in the later period of the equipment can be minimized to improve the work efficiency.

6. All the single use of the most advanced technology, greatly reduce the energy consumption, save the electricity bill.

7. The cooling mode of the equipment is air cooling, so users do not need to build cooling pools, thus saving capital

expenditure.

8. The equipment installation and debugging period is short, and all the work can be completed in about one month.

9. At present, the equipment has been sold to Syria, Sudan, Nigeria and other countries.

10. The oxygen equipment produced by our company is sold to more than 40 countries and regions, and the installation and debugging personnel have rich experience in overseas installation.

2. The user only needs to make the equipment workshop and the ground and lifting tools in the workshop, without preparing other installation materials and tools.

3. Small size and low footprint.

4. The whole set of equipment has no foundation installation, stable operation, simple operation and convenient maintenance.

5. Since the equipment adopts internal compression process, the maintenance cost in the later period of the equipment can be minimized to improve the work efficiency.

6. All the single use of the most advanced technology, greatly reduce the energy consumption, save the electricity bill.

7. The cooling mode of the equipment is air cooling, so users do not need to build cooling pools, thus saving capital

expenditure.

8. The equipment installation and debugging period is short, and all the work can be completed in about one month.

9. At present, the equipment has been sold to Syria, Sudan, Nigeria and other countries.

10. The oxygen equipment produced by our company is sold to more than 40 countries and regions, and the installation and debugging personnel have rich experience in overseas installation.

Contact Now

Please Send Message

${currentPro.title}