EN

Language

All categories

Product ID: 66689792

Complete Sweetened Concentrated Milk Production Line Equipment Solution

Contact Now

Description

产品描述

Product name

Sweetened concentrated milk production line complete equipment whole line solution

Professional condensed milk turnkey project manufacturer Over 15 years of condensed milk production line design ,manufacture and installation experience Top quality with reasonable price Supports on-site or remote guided installation and commissioning 7X24 hours after-sales and technical support

Video description

Products Description

Condensed milk production line description:

Raw material of condensed milk processing line - Fresh milk or powdered milk End product of condensed milk processing line -Sweetened condensed milk,which contains sugar -Unsweetened condensed milk,normally called evaporated milk which not contains sugar Processing Capacity of condensed milk processing line -5 T /D - 100T/D Container of condensed milk processing line -Bottles -Tin can

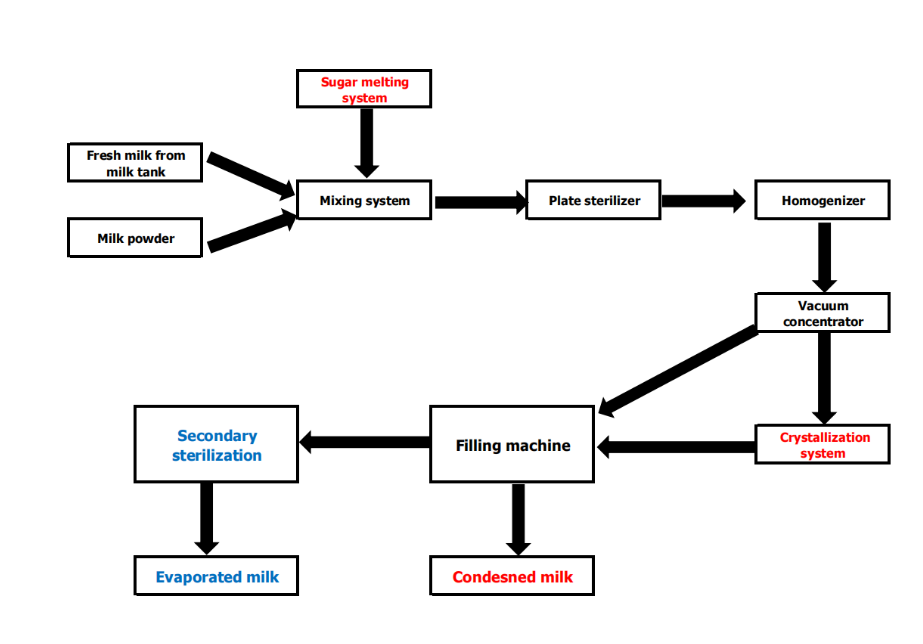

Condensed milk production line Flowchart :

|

Complete condensed milk Production Line equipment:

|

|

|

|

1

|

Raw milk storage system/milk powder and sugar dissolving system

|

|

|

2

|

Homogenization and pasteurization Section

|

|

|

3

|

Concentration system

|

|

|

4

|

crystallization system

|

|

|

5

|

Filling system

|

|

|

6

|

Secondary sterilization system

|

|

|

7

|

CIP system

|

|

|

8

|

Water Treatment system

|

|

|

9

|

Ice water system

|

|

|

10

|

Compressed air system

|

|

|

11

|

Steam Boiler

|

|

Condensed milk production line Key machine:

Fresh milk collection, cooling and storage system( fresh milk as raw material):

-If your fresh milk capacity per day is low , then the milk cooling tank will be used for cooling and storage fresh milk .

-If your fresh milk capacity per day is high, then need use the plate heat exchanger( PHE ) to cool down fresh milk to 4℃ and pump to milk storage tank

Milk powder and sugar dissolving system(Milk powder as raw material):

-Composed of mixing tank,high shear emulsification tank,water powder mixer and matched pumps, dissolving milk powder or ingredients with hot water .

-Sugar dissolving system only need when do Sweetened condensed milk

-Composed of plate pasteurizer, homogenizer, and centrifuge separator(Optional by client).

-Fresh milk →55-65℃ homgeonzer/separator→72-85℃/30S pasteurization

-Important and necessary step for both Sweetened condensed milk and evaporated milk production

-Milk Concentrated by removing a portion of the water content.

Contact Now

Please Send Message

${currentPro.title}