Commercial Peanut Butter Colloid Mill Grinding Production Line

Description

产品描述

Commercial Peanut Butter Colloid Mill Peanut Butter Grinding Making Machine Peanut Butter Production Line

This peanut butter production line is special designed by combined with domestic and foreign advanced technology and customer requirements. The placement direction of each machine can be specially set according to the specific size of the customer's workshop.

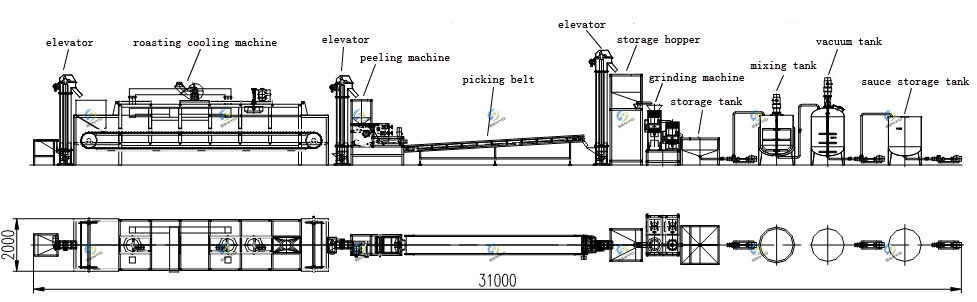

Main processing flow is elevator, roasting, cooling, peeling, grinding, mixing, vacuum degassing and packing.

Production Process

Roasting--cooling--peeling--grinding--mixing--vacuum degassing--packing

1. Roasting Machine: used to roasting raw peanuts. We have drum type and continuous type to choose from, according to different output requirements and customer plant configuration suitable models. The roasting temperature is 220-260 degree. Various methods can be used as the heat source, such as electric heating, natural gas heating and liquefied gas heating, etc.

2. Cooling Machine: used to cool roasted peanuts.

3. Peeling Machine: used to remove the red skin of roasted peanuts.

4. Picking Belt: used to pick bad peanuts or peanuts that are not completely peeled.

5. Combination Grinding Machine: used to grinding peanuts into peanut butter, after grinding twice, the fineness of peanut butter can reach 150 meshes, can meet the needs of consumers.

6. Storage Tank: used to storing the peanut butter, which acts as a buffer, the peanut butter passes through the storage tank and enters the mixing tank.

7. Mixing Tank: used to mixing peanuts. Add sugar, salt, oil and other seasonings to make different flavors of peanut butter.

8. Vacuum Degassing Tank: used to expel the bubbles in the peanut butter. The peanut butter after stirring in the mixing tank will produce bubbles. The degassing tank can eliminate the bubbles, extend the shelf life, and make the peanut butter more homogeneous.

9. Packing Machine: used to filling peanut butter into bottles, the filling volume can be 350ml, 450ml, 500ml, 1000ml etc.

Our company have professional engineers who can go to the customer’s factory to install and debug and teach customers how to use the machine; customers can also come to our factory to test the machine and learn how to operate the machine.

|

No. |

Name |

Dimension(mm) |

Power(kw) |

Quality |

|

1 |

Elevator |

1600*750*3000 |

0.75 |

1 |

|

2 |

Roasting cooling machine |

8500*1800*2600 |

130 |

1 |

|

3 |

Elevator |

900*750*3000 |

0.75 |

1 |

|

4 |

Peeling machine |

1900*800*1350 |

3 |

1 |

|

5 |

Picking belt |

6000*800*1000 |

0.75 |

1 |

|

6 |

Elevator |

900*750*3800 |

0.75 |

1 |

|

7 |

Storage hopper |

1200*1100*3300 |

0.04 |

1 |

|

8 |

Grinding machine |

1400*1250*2000 |

30x2 |

2 |

|

9 |

Sauce storage tank(500L) |

1300*1300*900 |

|

1 |

|

10 |

Mixing tank(500L) |

1000*1000*1900 |

3 |

1 |

|

11 |

Vacuum tank(500L) |

900*900*2500 |

3+1.5 |

1 |

|

12 |

Paste pump |

1200*300*350 |

1.5x3 |

1 |

|

13 |

Sauce storage tank(500L) |

900*900*1200 |

|

1 |

|

14 |

Control cabinet |

|

|

2 |

|

15 |

Pipeline |

|

|

${currentPro.title}