EN

Language

All categories

Product ID: 68042135

PUHUI T-961 Infrared Hot Air Reflow Oven with 6 Heating Zones for High Precision Soldering

Contact Now

Description

Product description

Features

1.Description of products

The Infrared IC Heater T961 is a microprocessor-controlled reflow-oven. This machine uses the intelligent level sirocco and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. It is suitable for high welding temperature lead-free solder paste and can be used for effectively soldering various SMT and BGA components.

2. Products features

(1) Have big infrared soldering max area.

Soldering area to reach effectively :230x730mm, Increase the usage scope of this machine consumedly, economical investment.

(2) Many temperature wave choice for you.

Memory eight kinds of temperature parameter waves can be provided as choice, and establish to move heating and cool off function compulsory;Whole soldering process to complete automatically, easy to use.

(3) Special heat up and temperature equalization with all design.

Output the power reaches to a 3500 W, Adoption fast infrared radiation and circulation the wind for heat,so the temperature is very Accurate and even, Whole soldering process to complete automatically for you choice temperature parameter waves.

(4) Humanized science and technology exquisite article.

Firm of external appearance, can see of operation, amity of person machine operation interface, the perfect temperature wave project, from start to eventually body science and technology now is originally; The agile physical volume and weight, let you economize a great deal of money, the set noodles type places mode, can let you own larger space; Simple operating instructions, let you a see can use.

(5) Perfect function choice.

Return soldering, drying, heat preservation, finalize the design, fast cool off etc.can use Can soldering the most smart small part example CHIP,SOP,PLCC,QFP,BGA etc; Can used to the gum of the product solid turn, the circuit board is hot aging, the PCB plank maintains to wait various works.Be applicable to each kind of business enterprise,company extensively develop and the small batch quantity produce a demand.

The Infrared IC Heater T961 is a microprocessor-controlled reflow-oven. This machine uses the intelligent level sirocco and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. It is suitable for high welding temperature lead-free solder paste and can be used for effectively soldering various SMT and BGA components.

2. Products features

(1) Have big infrared soldering max area.

Soldering area to reach effectively :230x730mm, Increase the usage scope of this machine consumedly, economical investment.

(2) Many temperature wave choice for you.

Memory eight kinds of temperature parameter waves can be provided as choice, and establish to move heating and cool off function compulsory;Whole soldering process to complete automatically, easy to use.

(3) Special heat up and temperature equalization with all design.

Output the power reaches to a 3500 W, Adoption fast infrared radiation and circulation the wind for heat,so the temperature is very Accurate and even, Whole soldering process to complete automatically for you choice temperature parameter waves.

(4) Humanized science and technology exquisite article.

Firm of external appearance, can see of operation, amity of person machine operation interface, the perfect temperature wave project, from start to eventually body science and technology now is originally; The agile physical volume and weight, let you economize a great deal of money, the set noodles type places mode, can let you own larger space; Simple operating instructions, let you a see can use.

(5) Perfect function choice.

Return soldering, drying, heat preservation, finalize the design, fast cool off etc.can use Can soldering the most smart small part example CHIP,SOP,PLCC,QFP,BGA etc; Can used to the gum of the product solid turn, the circuit board is hot aging, the PCB plank maintains to wait various works.Be applicable to each kind of business enterprise,company extensively develop and the small batch quantity produce a demand.

· Wide Soldering Area

· Effective Temperature Control

· Stable Transmission System

· Convenient Control

· Professional Use

· Effective Temperature Control

· Stable Transmission System

· Convenient Control

· Professional Use

Specifications

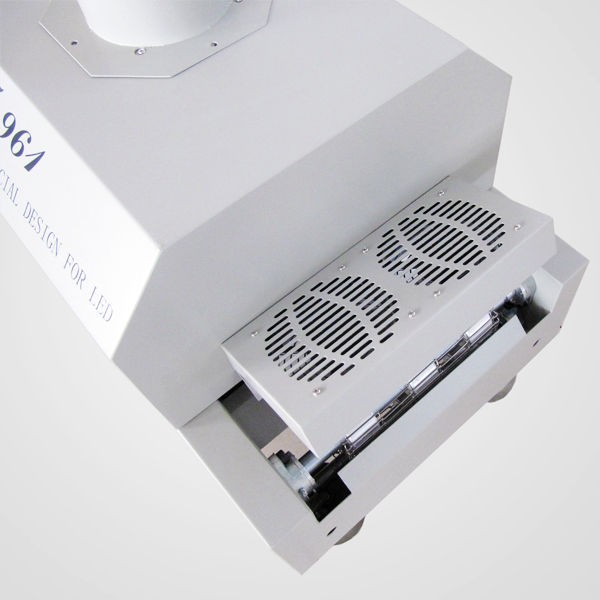

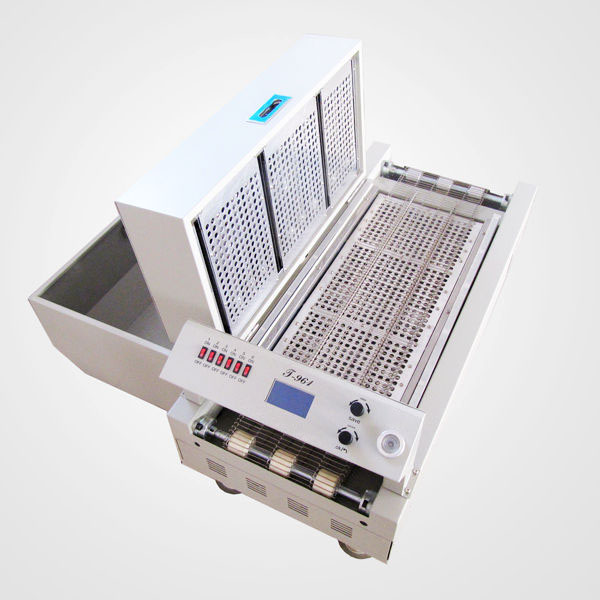

· Model: T-961

· Heating Zone: upper 3 / down 3

· Soldering Area: 230 x 730 mm

· Voltage: 220V/110V, 50HZ/60HZ

· Length of Heating Zone: 730 mm

· Max Width of PCB Board: 230 mm

· Rated Power: 3.5KW

· Speed of Conveyor Belt: 0-290mm/min

· Heating Up Time: Around 7min

· Temperature Control Range: Room temperature - 300 ℃ / 572 ℉

· Temperature Control Accuracy: ± 1℃

· Temperature Distribution Deviation: ± 2℃

· Heating Zone: upper 3 / down 3

· Soldering Area: 230 x 730 mm

· Voltage: 220V/110V, 50HZ/60HZ

· Length of Heating Zone: 730 mm

· Max Width of PCB Board: 230 mm

· Rated Power: 3.5KW

· Speed of Conveyor Belt: 0-290mm/min

· Heating Up Time: Around 7min

· Temperature Control Range: Room temperature - 300 ℃ / 572 ℉

· Temperature Control Accuracy: ± 1℃

· Temperature Distribution Deviation: ± 2℃

· Heating Mode:Infrared & Hot Air

· Temp Cantrol:PID closed-loop control

· Direction:left-right

· Cooling zone:1

· L*W*H (mm):1000*466*445mm

· Machine Weight:70kg

· Gross Weight:90kg

Contact Now

Please Send Message

${currentPro.title}