EN

Language

All categories

Product ID: 68070664

WelderNeed LGK-120 DC ARC IGBT Inverter Cut Welder - Best Price

Contact Now

Description

Product description

OEM / OBM / ODM supported

customize for you

Regardless of color or logo;

Regardless of current or voltage;

No matter the button or the chip;

Regardless of accessories or packaging!

just for you .

Make Partner Win

Products Description

LGK120 380V 120AMP Plasma Cutter for cutting welding machine

PLASMA CUT WELDING MACHINE

Product Paramenters

|

Input voltage

|

Входное напряжение

|

3⁓380V 50Hz

|

|

Input Current

|

Входной ток

|

34.6A

|

|

Rated input capacity

|

Номинальная входная мощность

|

22.4KVA

|

|

No-load voltage

|

Напряжение холостого хода

|

300V

|

|

Current adjustment range

|

Диапазон регулировки тока

|

30-120A

|

|

actual output current

|

фактический выходной ток

|

120A

|

|

Inversion frequency

|

частота инверсии

|

19.4KHz

|

|

efficiency

|

КПД

|

85%

|

|

power factor

|

коэффициент мощности

|

0.8

|

|

Protection class

|

Класс защиты

|

IP21S

|

|

Insulation class

|

Класс изоляции

|

F

|

|

Rated Duty Cycle @40°C:

|

Номинальный рабочий цикл @40°C:

|

100%

|

|

Quality cutting board thickness

|

Применяемая сварочная проволока

|

0.3-35mm

|

|

Maximum Cutting Thickness

|

Толщина сварочной пластины

|

50mm

|

|

Net weight (Kg)

|

Вес нетто (кг)

|

35

|

|

Body size (mm)

|

|

580×314×565

|

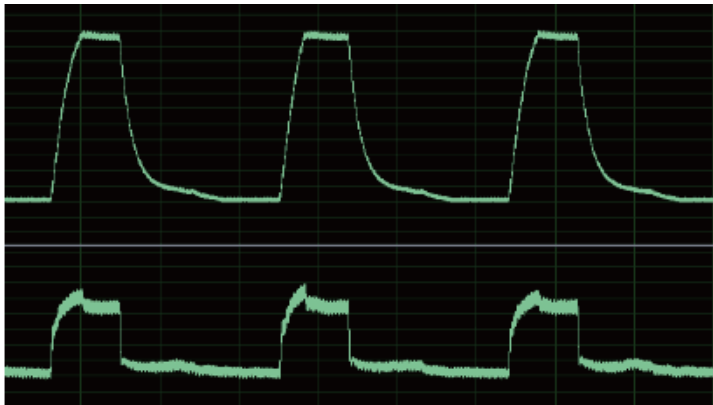

HSP - High Speed Pulse

①Specifically designed for demanding workshop use,the deposition rate can increase 25~48 % for various materials, whether used in manufacturing thick materials or sheet metal.②The High-Speed Pulse(HSP) process enables you to save time, money, and energy compared to traditional pulse welding. This process is ready to raise pulse welding to a whole new level!

③In general, One pulse melt one droplet, but we increase the submission of these droplets by TOPWELL’ s New High-Speed pulse process.The transition will be faster, narrower HAZ zone and deeper penetration!

③In general, One pulse melt one droplet, but we increase the submission of these droplets by TOPWELL’ s New High-Speed pulse process.The transition will be faster, narrower HAZ zone and deeper penetration!

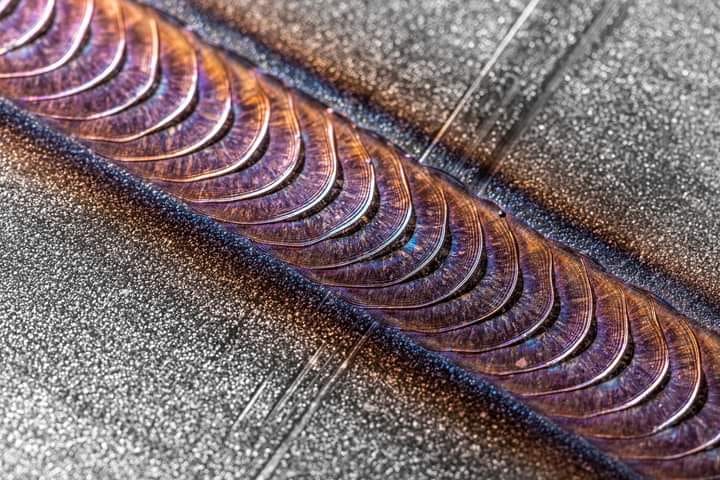

Get better welding seam

Less heat input, less spatters, less rework

Get higher welding strength

Deeper penetration, no undercut defects, higher strength.

Contact Now

Please Send Message

${currentPro.title}