Tubular Chipboard Production Line / Hollow Core Particle Board Production Line

Description

Product description

Tubular chipboard production line

Hollow core particle board line is used to produce hollow core particle (chip) boards. The board is popularly used to buildings, decoration, advertisement ornament, sound insulation on road and packaging. The PP hollowness board can replace the paper packaging canton with the advantages of light weight, high strength, damp-proofing and corrosion-resistance. The width of the board is 1220-3000 mm; thickness is 2-16mm .

Hollow core particle board line can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet, etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing. It is widely used in such fields as the electron, household electrical appliances, packaging,- machinery, postal, food, medicine, pesticide and advertisement decoration, etc.

1. Main data of hollow core slab machine

| --Voltage |

380v/ 415v |

| --Capacity | 5,000~30,000 m3/year |

| --Board Size | 1200*2400mm (4*8ft), 24~45mm |

| --Raw Material | Wood Branch, log, waste wood, sawdust and left overs |

| --Control Method | PLC, CNC |

2. Equipments list of hollow core slab machine

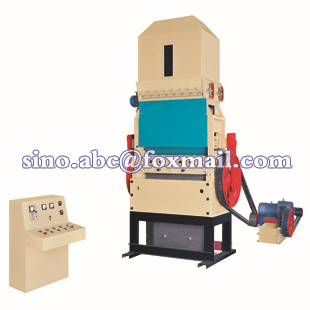

| --Hollow core particle board hot press | |

|

|

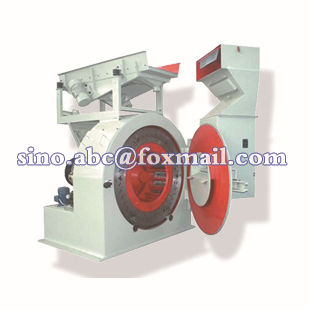

| --Drum chipper | --Knife-ring flaker |

|

|

| --Belt conveyor | --Screw conveyor |

|

|

| --Vibrating screen | --Feeder |

|

|

| --Hot air dryer | --Glue blender |

|

|

3. Finished Boards

|

|

${currentPro.title}