OSB Making Machine for Furniture Manufacturing Plants - RF Technology Based on Raw Material, 380V, 8-25mm Thickness

Description

Product description

OSB production line/ OSB making machine,OSB production line machine

OSB production line is based on wood as raw materials, shavings, glue, auxiliary equipment, hot pressed density 550-750kg / M 3 man-made sheet. osb making machine has a fine smooth surface structure of the core layer gradient, and has good heat insulation, sound insulation and good machining properties

1) Chip preparation section Osb Production Line/Osb Board Making Machine

Raw material is reduced into qualified chips by the drum chipper, then the chips are

transported to the chip bin, and then feed to the knife-ring flaker by which the chips are turned

to flakes,then the flake stored in wet flake bin.

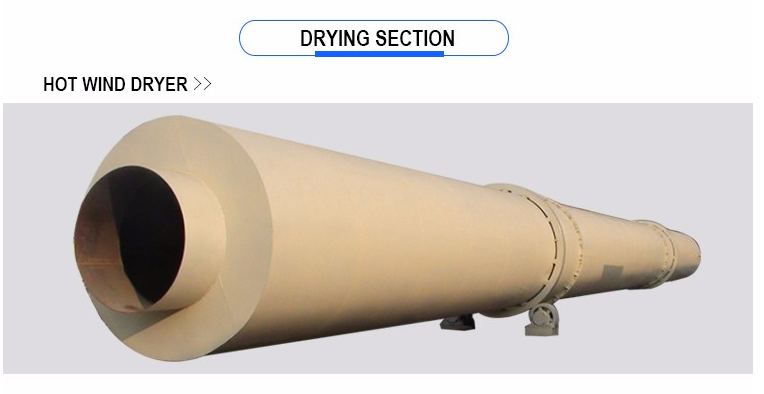

2) Drying and sifting section Osb Production Line/Osb Board Making Machine

The flakes discharged from the wet flake bin are conveyed to the rotary dryer. Qualified core

flakes are stored in core flake bin; oversize flakes are send to mill to be re-crushing,

and transported to surface flake bin.

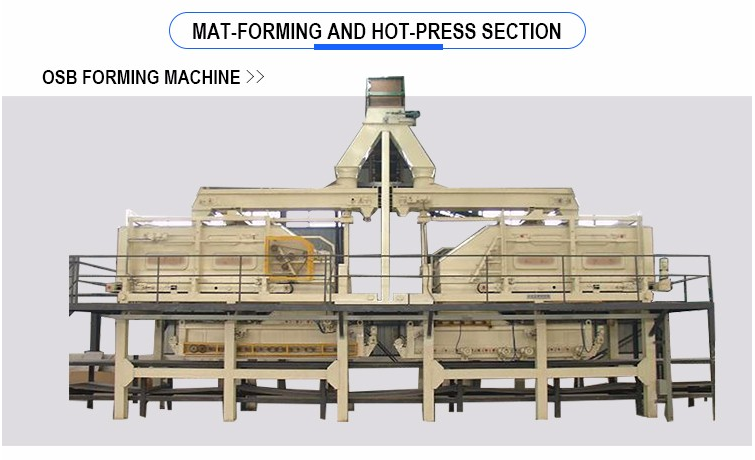

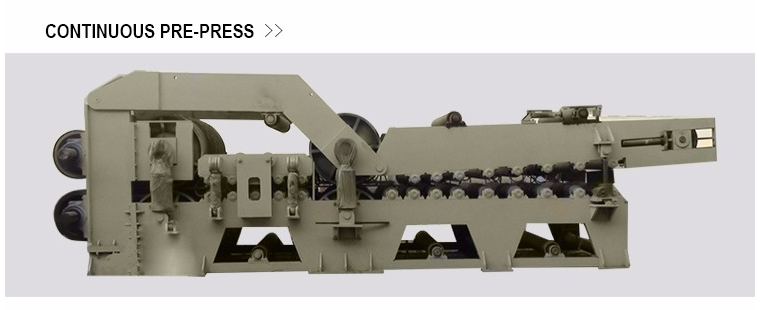

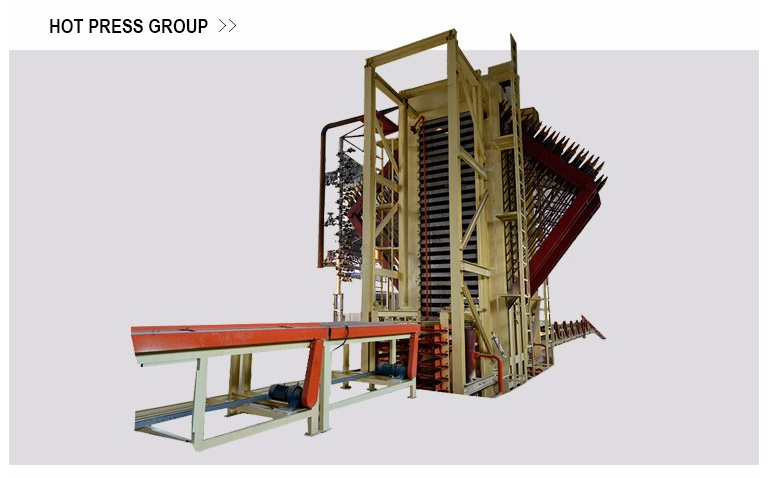

3) Forming and hot-pressing section

The surface and core flakes are sent into classi-forming machine, and forming on the mat

conveyor uniformly. After process of metal remover , pre-press, lengthwise saw, cross saw,

accelerate conveyor,scaling conveyor , storing conveyor and loading conveyor,mats are

transported to carrier and then to hot pressing. Rough boards after pressing are pushed to

unloader via pallet.

4) Cooling and sizing section Osb Production Line/Osb Board Making Machine

The rough board is conveyed to star-cooler for cooling ,then the rough board goes through

side trimming saw and become a qualified particle-board, stacked on the hydraulic lift.

5) Sanding section Production Line/Osb Board Making Machine

The board are sanded,checked and stored.

PLC control is used in mat-forming section.

${currentPro.title}