Wood Plywood Making Machinery: Veneer Scarf Joint Machine

Description

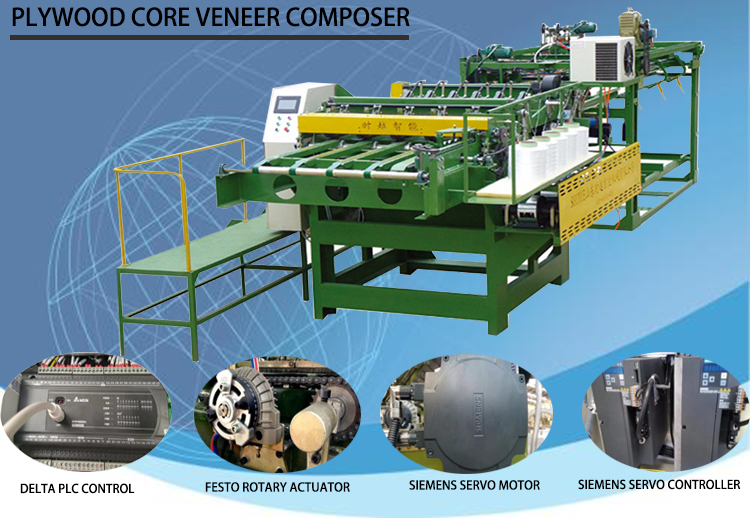

Product description

Application

Core veneer jointer machine is suitable for core joining together in plywood production line. It can work different length sizes of core veneer with high strength thread and hot melt adhesive connection as one whole body Then facilitate the subsequent stages of production of plywood line. The whole process can be operated by one worker, it is time-saving and efficient.

1.Working principle

The core veneers (1.0-4.0mm thickness panels) after drying may have different length and thickness, and the shapes may get irregular, this core veneer composing machine can detect width, thickness, cavities of the core veneer , trimmed, glued, composed, cut to length and stacked automatically. With this machine, the core veneer with different sizes can be composed in one whole sheet.

2.Working process

1. feeding delivery----2. plate correction----3.the former drive----4. cut and control-----5. after the drive----6.docking puzzle----7.finished plate cut off The entire operation process only by a person operation. Finished plate, small material in the board, abandoned scrap, can be stitching, not only saves the cost, but also saves the artificial.

Parameter

|

SPECIFICATIONS FOR 4 FT PLYWOOD CORE VENEER JOINTING MACHINE |

|||

|

Driver system |

Driver |

Servo-type |

Siemens servo motor |

|

Cutter driver |

motor+electromagnetic clutch |

Taiwan Chain Tail clutch |

|

|

Driver reducer |

Star type reducer |

8/1 |

|

|

Dimension |

complete machine |

L*W*H(mm) |

12000*2600*2500 |

|

Jointing machine |

L*W*H(mm) |

3600*2600*2500 |

|

|

veneer stacker |

L*W*H(mm) |

4000*2200*2500 |

|

|

Control system |

Control module |

PLC computer module |

TDATDA PLC |

|

rotary actuator |

photoelectric sensor |

FESTO(germany) |

|

|

Heating control |

* |

Automatic Control |

|

Characteristic

1.PLC control, unmanned operation, automatic process, laborsaving

2.Precise thickness checking, even thickness, mini polishing

3.Servo drive, effective overlap and joint control

4.Supported by German Festo, Danfoss, Taiwan Taida, Japanese Mitsubishi and other international to level brands.

5.High strengthened thread, improve product horizontal tensile force and flexibility, no break

Presale service

Ⅰ.Make reliable pratical mechine list and production proposal free of charge, according to customers' actual situation

Ⅱ.Design the machine free of charge, according to customer's production line and production cost,

Ⅲ. Make the workshop and production line layout free of charge, according to customers' factory land

Medium-sales service

Ⅰ.Video for the manufacturing process as customers requirement

Ⅱ.Machine modifying according customers' suggestion

Ⅲ.Order the shipment and prepare the documents for customers' clearance, according to customers' custom requirement

After-sale services

Ⅰ.One year warranty for main machine, cost price for vunerable parts

Ⅱ.Experienced engineer is avaiable for the machine installation and worker training

Ⅲ.Cooperate with Aliyun OS, remote control of trouble shoting and system upgrading

Linyi Ruifeng Machinery Manufacturing Co.,Ltd is located in Linyi city, the world largest wood-based panel producing base, with 25 years development, Linyi Ruifeng become one of the leading wood-based panel machinery equipment developer and manufacturer, till now we have exceed 80 experienced engneer and an installation and training team of 20 experienced workers.We can manufacture and install most WBP producing line(including plywood making line, particle board line, OSB producing line, MDF production line) according to customers' requirement independently.

"Honesty, Responsibility, Innovation" is our company's principles, anytime give our customers honest treatment, be responsible to our products and guest, continuously innovate to make better machine, to give customers better service. With Ruifeng people 25 years hard working, now our machines and lines have already exported to more than 50 countries and locations. We believe that through our struggling, Linyi Ruifeng will be famous worldwide in the near future.

${currentPro.title}