Six Side Drill Double Boring Heads For Furniture

Description

Product description

Wood Panel Furniture Making Six Side Drilling Machines

Overview:

PTP 6 Sides Drilling Machine Hot Sale Woodworking Fully Automatically CNC 6 Sides Boring Machine for Wood Panel.

6 sides hole drilling machine JX2412-6F is a special high-speed and comprehensive punching machine independently developed by JINGXUN Company.Professional customized drilling can achieve the least avoidance and fundamentally increase the drilling speed.The original peeling function makes the punching smoother and maximizes the plate yield.High-end air-floating table tops make the processing more precise.

1. finish six-side different types hole drilling and slotting on wood

2. Front and back card slot

3. Pneumatic float on table

4. Compatible with XML, MPR, etc

5. Teardown software seamless docking

6. Scan bar code without programming

7.The pusher facilitates material’s transportation, advanced intelligent laser coding function.

8. This machine is suitable for Panel Furniture, Office Furniture and Full-house Custom Furniture etc.

Upper drilling

L-shaped (12V4H) custom layout is adopted, the punching spacing can be minimized, and the punching efficiency can be improved

Lower drilling

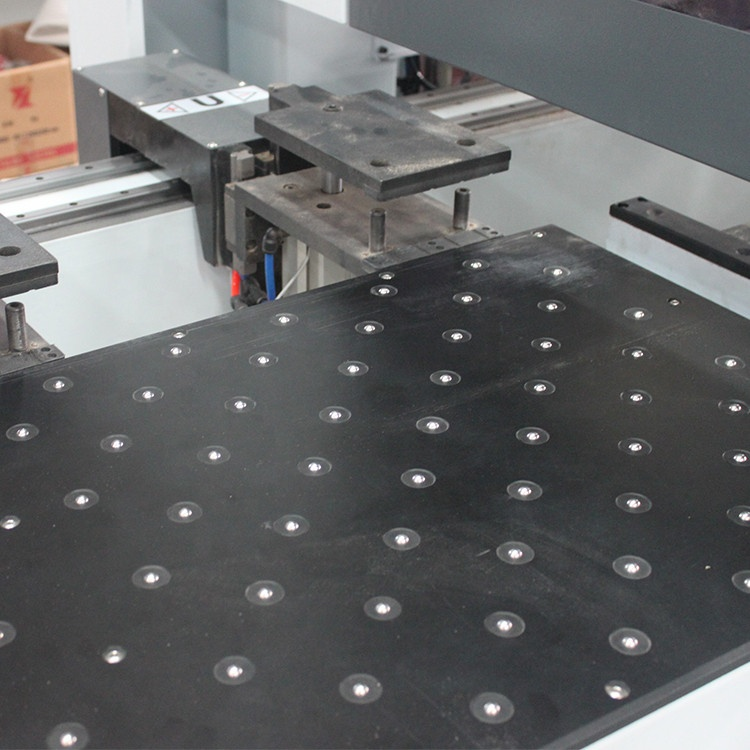

Table

Guide rail

Advantages:

6 sides hole drilling machine Advantage:

1. The process is highly concentrated, one-time clamping can complete the drilling of six sides of the workpiece and the slotting on the upper and lower sides of the workpiece.

2. High-speed gripper structure,makes processing more efficient; automatically detects the relevant dimensions of the plate to prevent manual errors.

3. The working table is filled with pneumatic floating beads, and it is easy to move the board on the table without scratching the board. According to the user's production needs, you can choose different discharge methods (forward and forward, forward and backward), and also choose the discharge method of the discharge platform or air floating table.

4. The original skin-breaking function makes the punching smoother and maximizes the yield of the plate.

5. The high-end air float table makes the processing more accurate.

6. Open software docking interface, compatible with many kinds of docking formats.

7.Lapping rails, which comes with steel belts, greatly improves the dustproof performance of the guide rails.

8. High technology compact machine making possible to drill holes on 6 sides, groove top and bottom, route shapes in one process without necessary of turning panel. Continuous working for various batch sizes and patterns to fit complex production. High accuracy and processing effective, basically no complaints.

9. Easy production management due to self-recording function. Automatic detection of panel size reducing man made mistakes. Adjustment of panel position by best compensation automatically to suit furniture assembly process. Open port for international popular software, compatible with many file formats like xml, mpr etc.

10. Choosing from powered or simple roller conveyor for feeding in and out of panel to form a production line based on requirements.

Ability of JINGXUN2812

● Pure six-sided, 8 hours working time 700-800 pieces panels any size (punching and slotting)

● Five-sided and six-sided mixed, 8 hours work time 900-1100 pieces panels any size (punching and slotting)

● Pure five-panel parts, 8 hours working time ,the qantity of panels any time 1000-1200 pieces (punching and slotting)

● Pure punching five panels, 8 hours working time, the Quatity of panels is 1300-1500 pieces (pure punching)

${currentPro.title}