EN

Language

All categories

Product ID: 68262259

KINCNC Furniture Wood Processing 6-Sided CNC Drilling & Boring Machine for Cabinets, Doors, & Plywood Panels

Contact Now

Description

Product description

Products Description

|

Processing size range&speed |

Panel maximum length

|

4250mm

|

|

|

Panel minimum length

|

200mm

|

|

|

Panel maximum width

|

1250mm

|

|

|

Panel minimum width

|

30mm

|

|

|

Panel maximum thickness

|

50mm

|

|

|

Panel minimum thickness

|

10mm

|

|

|

Fastest processing speed

|

80m/min

|

|

Main details

|

Number of Motion axis

|

7

|

|

|

Processing surface

|

6

|

|

Drilling bags & configuration |

Number of drill bags

|

Upper: 1

Lower: 1 |

|

|

Upper vertical drill bit

|

7 pcs

|

|

|

Upper horizontal drill bit

|

4 pcs

|

|

|

Lower vertical drill bit

|

3 pcs

|

|

Spindle

|

Upper spindle

|

1

|

|

|

Lower spindle

|

1

|

|

|

Spindle power & speed

|

3.5kw & 2400rpm

|

|

|

X axis

|

3800mm & 130m/min

|

|

|

Y axis

|

2500mm & 90m/min

|

|

|

Z axis

|

150mm & 60m/min

|

|

|

A axis

|

3800mm & 90m/min

|

|

|

U axis

|

1500mm & 60m/min

|

|

|

V axis

|

1250mm & 90m/min

|

|

|

W axis

|

1250mm & 90m/min

|

|

|

Total power

|

22.8kw

|

|

|

Tool diameter

|

4-35mm (optional)

|

|

|

Working voltage

|

380V/50HZ or as your request

|

|

|

Working pressure

|

0.6-0.8Mpa

|

|

|

Weight

|

4300kg

|

|

|

Overall size

|

4600*2650*2100mm

|

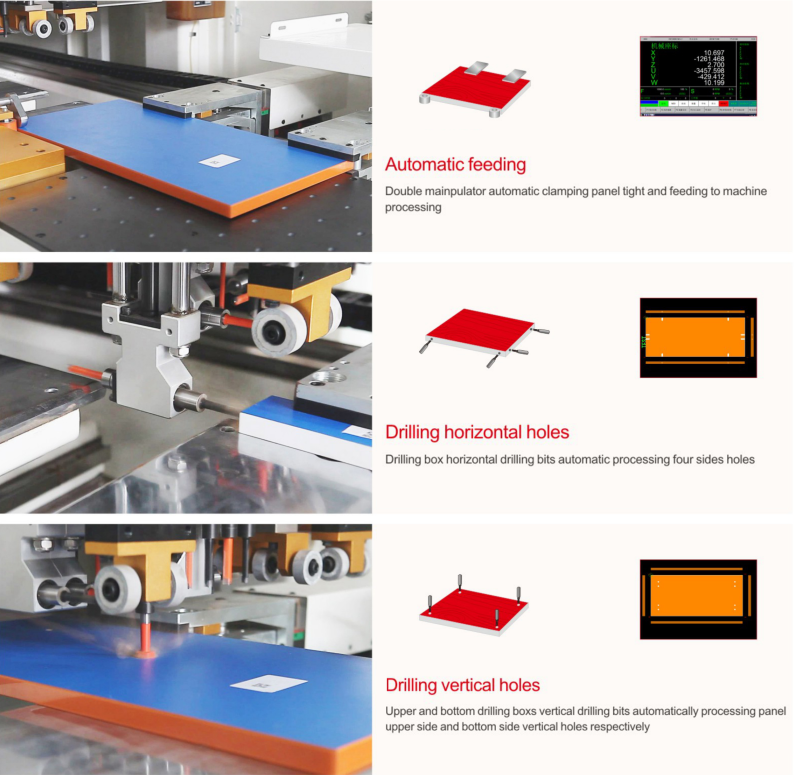

Application: It is suitable for panel furniture, house custom, cabinet wardrobe custom and other industries. The machined boards include: MDF, particle board, ABS board, PVC board, solid wood, ecological board, multi-layer board, wave board, insulating board, acrylic and other boards. Performance Characteristics: 1.Complete six-sided drilling, slotting and milling processing at one time. 2.Adopt Taiwan original SYNTEC integrated control system. 3.Diversified data docking ports, directly import processing data, realize intelligent and seamless production. 4.The machine can be connected to all kinds of software in the market, and it can recognize mpr/ban/xml.dxf/xxl/bpp/bd and other format files. 5.Adopting Taiwan high-precision rack and pinion transmission, the precision of rack and pinion transmission reaches 0.1mm, and the service life is improved. 6.Use air-floating worktable; the worktable can move up and down, front and back together with the plate, reducing plate friction, scratches, and collisions. 7.Ultra-long stroke double-grabbing device; intelligent optimization and fast clamping, one-time grasping of the workpiece, and fast and flexible switching of processing large and small plates. 8.Servo positioning and supporting board device can automatically position according to the size of the plate, improve positioning accuracy and stabilize processing accuracy. 9.800-1500 workpieces can be completed in 8 hours. Detailed Description : 1.Double linkage pneumatic gripper can automatically clamp panel tightly and feed it to the machine processing. 2.The horizontal drill bits can automatically process four sides holes. 3.The vertical drill bits can automatically process panel upper side and bottom side, drilling the vertical holes respectively. 4.According to the panel size, it can automatically align panel side tightly to detect panel width and avoid panel dislocation. 5.According to the slot information automatic make slot,cutting and milling functions. 6.Automatically transport the panel to unloading device, you can choose the workpiece back side unloading.

Contact Now

Please Send Message

${currentPro.title}