EN

Language

All categories

Product ID: 68588452

High Quality Ruiqin DIN6796 SS304 Belleville Spring Washer

Contact Now

Description

Basic Info.

Model NO.

DIN6796

Combination Washer Structure

A Type

Combination Washer Packaging

All Inclusive

Spring Washer Type

Standard

Surface Treatment

Natural Polished Finish (Bright Annealed)

Application

Used in Between The Nut and Bolt.

OEM

Available

Spring Load Capacity

High Load, Ideal for Pre-Tensioning Applications

Hardness

HRC 44–52

Transport Package

Carton+Pallet

Specification

M3 – M36 (Customizable)

Trademark

RUIQIN

Origin

China

HS Code

7318150000

Production Capacity

200000000piece/Years

Packaging & Delivery

Package Size

20.00cm * 10.00cm * 10.00cm

Package Gross Weight

5.000kg

Product Description

Product Description

DIN6796 Belleville washers feature a unique conical disc design, with a thick center and thin edges, providing excellent elasticity and high preloading force to maintain constant clamping pressure in bolt connections, effectively preventing loosening and fatigue relaxation. Its outstanding vibration and impact resistance make it ideal for automotive suspension systems, engine fasteners, wind power equipment, and machinery in high-vibration, high-load environments.

Key Features of 304 Stainless Steel 304

304 stainless steel is a high-quality, non-magnetic material known for its excellent corrosion resistance, durability, and clean appearance. It performs well in harsh environments, is easy to form and weld, and is widely used in applications requiring hygiene, strength, and long-term reliability.

Other materials and finishes are available | merit |

65Mn + Dacromet | Superior corrosion resistance and high-strength performance. |

65Mn + Black Oxide | Enhanced wear resistance and anti-corrosion properties. |

65Mn + Blue-White Zinc | Excellent rust protection with a clean, bright finish. |

65Mn + Color Zinc Plating | Provides corrosion resistance with a bright, attractive finish for 65Mn spring steel. |

SS304 + Natural Polishing | Outstanding corrosion resistance and a smooth, polished surface. |

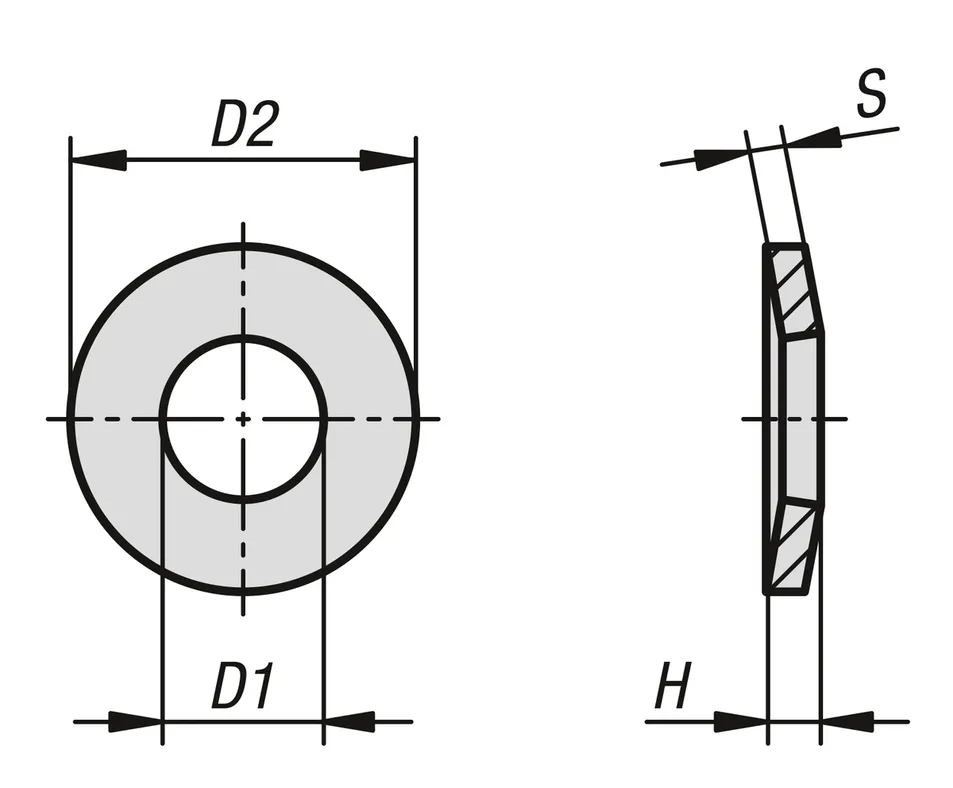

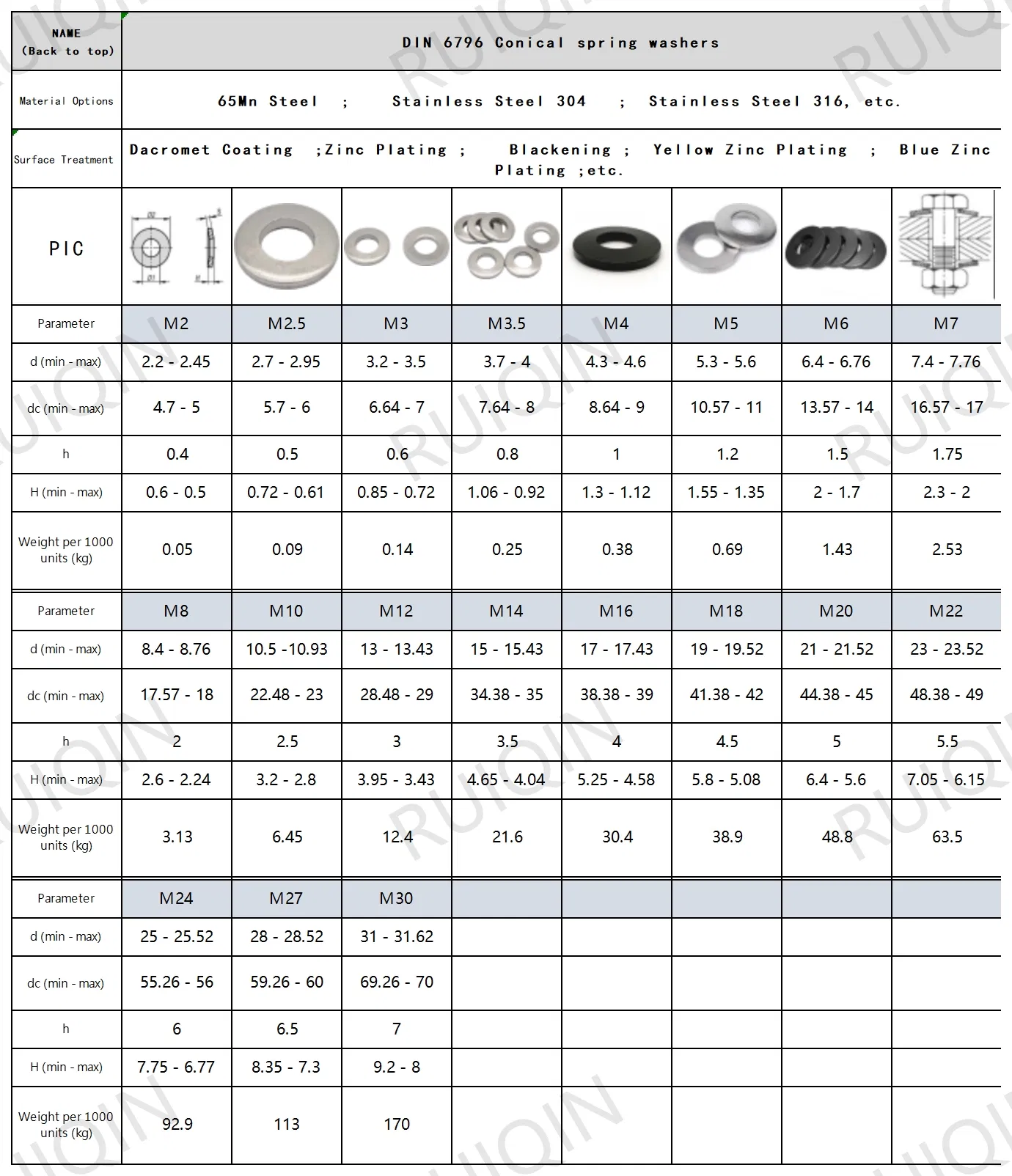

Specification

Product Applications

Functional Features of DIN6796 Belleville Washer

1. Anti-Loosening

The conical design provides constant pressure to prevent bolt loosening.

2. Vibration Resistance

Effectively absorbs vibrations to avoid bolt detachment.

3. Load Distribution

Evenly spreads pressure to prevent localized stress.

4. Compensation for Bolt Relaxation

Automatically adjusts for bolt relaxation over time.

5. Enhanced Preload Stability

Maintains strong connections and reduces maintenance.

The conical design provides constant pressure to prevent bolt loosening.

2. Vibration Resistance

Effectively absorbs vibrations to avoid bolt detachment.

3. Load Distribution

Evenly spreads pressure to prevent localized stress.

4. Compensation for Bolt Relaxation

Automatically adjusts for bolt relaxation over time.

5. Enhanced Preload Stability

Maintains strong connections and reduces maintenance.

Engine Mounting System

Belleville washers are used for bolt fastening on engine covers, cylinder heads, and intake/exhaust manifolds, effectively preventing loosening caused by high temperatures and vibrations, ensuring long-term stable operation of the engine.

Suspension System

In automotive suspension systems, Belleville washers are used for fastening connectors and brackets, providing excellent shock resistance and preventing loosening caused by road impacts.

Brake System

Applied to the fastening bolts of the brake master cylinder and brake discs, enhancing thread vibration resistance to prevent loosening during high-speed braking, ensuring driving safety.

Transmission Mounting Bolts

At the connection between the transmission and the engine, Belleville washers effectively prevent loosening caused by intense vibrations during power transmission, ensuring smooth power output.

Packaging & Shipping

Minimum Unit Packaging

Inventory and Quick Delivery

Secure Carton Packaging

Our minimum unit packaging consists of plastic bags, with different quantities based on the washer size and specifications. Commonly, each bag contains 1000, 500, or 200 pieces, ensuring easy handling and efficient storage.

We maintain a reliable inventory of all sizes and materials of our products, ensuring fast delivery for in-stock items. Our commitment to sufficient stock levels allows us to support immediate shipment to meet your urgent needs efficiently.

The plastic bags are placed inside sturdy cartons, securely sealed with tape and zip ties to prevent movement and damage during transportation, ensuring your products arrive safely and in perfect condition.

Pallet Packaging and Protection

Container Loading

Shipping Methods

The cartons are neatly stacked on pallets, secured with zip ties and reinforced with wooden edge protectors for added stability. Finally, the entire pallet is wrapped with stretch film to ensure safe and damage-free transportation.

Pallets are systematically loaded into containers, ensuring maximum space utilization and secure placement. Our team follows strict loading procedures to prevent shifting during transit, guaranteeing that your products arrive safely and intact.

For large-volume orders, we arrange ocean freight to ensure cost-effective and reliable delivery. For small-sized orders, we offer express shipping for faster transit, meeting different customer needs with flexibility and efficiency.

Founded over 20 years ago, Ruiqin Standard Parts has grown into a leading manufacturer of high-quality washers and fasteners. Located in the heart of China's automotive parts industrial hub, we leverage local advantages for cost control and technological optimization. With a strong production and delivery capability, we ensure reliable and timely supply to our global clients. Our products are widely exported to Europe, South America, and Southeast Asia, where they are trusted for their durability and precision. At Ruiqin, we are committed to providing exceptional quality and service, supporting your projects with efficient, cost-effective solutions.

Experienced Technical Team

Sufficient Inventory with Full Specifications and Materials

Automated Production Lines for Rapid and Stable Output

Our team consists of highly skilled technicians with many years of industry experience, ensuring precision and reliability in every product. Their expertise enables us to meet complex requirements and deliver consistent quality across all orders.

We maintain a comprehensive inventory of washers in a wide range of specifications and materials, allowing us to support large orders and urgent demands. Our well-organized stock ensures quick dispatch and uninterrupted supply.

Equipped with advanced automated production lines, we achieve high efficiency and stable output, meeting tight deadlines while maintaining superior quality. Our modern manufacturing capabilities ensure reliability and scalability for global markets.

FAQ

issue | Reply |

Can I customize the size, material, and surface treatment of the washers? | Yes, we offer full customization options, including size, material (65Mn, stainless steel, etc.), and surface treatment (Dacromet, zinc plating, etc.) to meet your specific requirements. |

What is the typical lead time for bulk orders? | Our standard lead time is 15-30 days, depending on the order quantity and product specifications. We can also coordinate delivery schedules to match your project timeline. |

Do you support small trial orders? | Yes, we accept small trial orders to help you test the quality and fit of our products before placing larger orders. |

Which shipping methods do you provide? | We offer a range of shipping methods, including ocean freight for bulk orders and express delivery for smaller quantities. |

Can you provide samples before placing an order? | Yes, we provide free samples, but the shipping cost is covered by the buyer. |

What regions do you export to? | We mainly export to Europe, South America, and Southeast Asia, with strong experience in handling international logistics and customs procedures. |

How do you ensure product quality? | We have a strict quality control system, including raw material inspection, in-process checks, and final product testing to ensure every item meets industry standards. |

Is your packaging safe for international shipping? | Yes, our products are securely packed in plastic bags, cartons, and reinforced pallets, with additional wrapping to prevent damage during transit. |

Can you help with custom labeling and packaging? | Yes, we offer custom labeling and packaging solutions to match your brand requirements. |

What payment terms do you accept? | We support T/T, L/C, and other negotiable terms, and we are flexible to accommodate your financial arrangements. |

Contact Now

Please Send Message

${currentPro.title}