Low-Maintenance Grate Cooler Plate with Reinforced Structure and Anti-Clogging Design

Description

Overview

Model NO.: GC-500X

Application: Construction, Chemical Industry, Mineral Operation

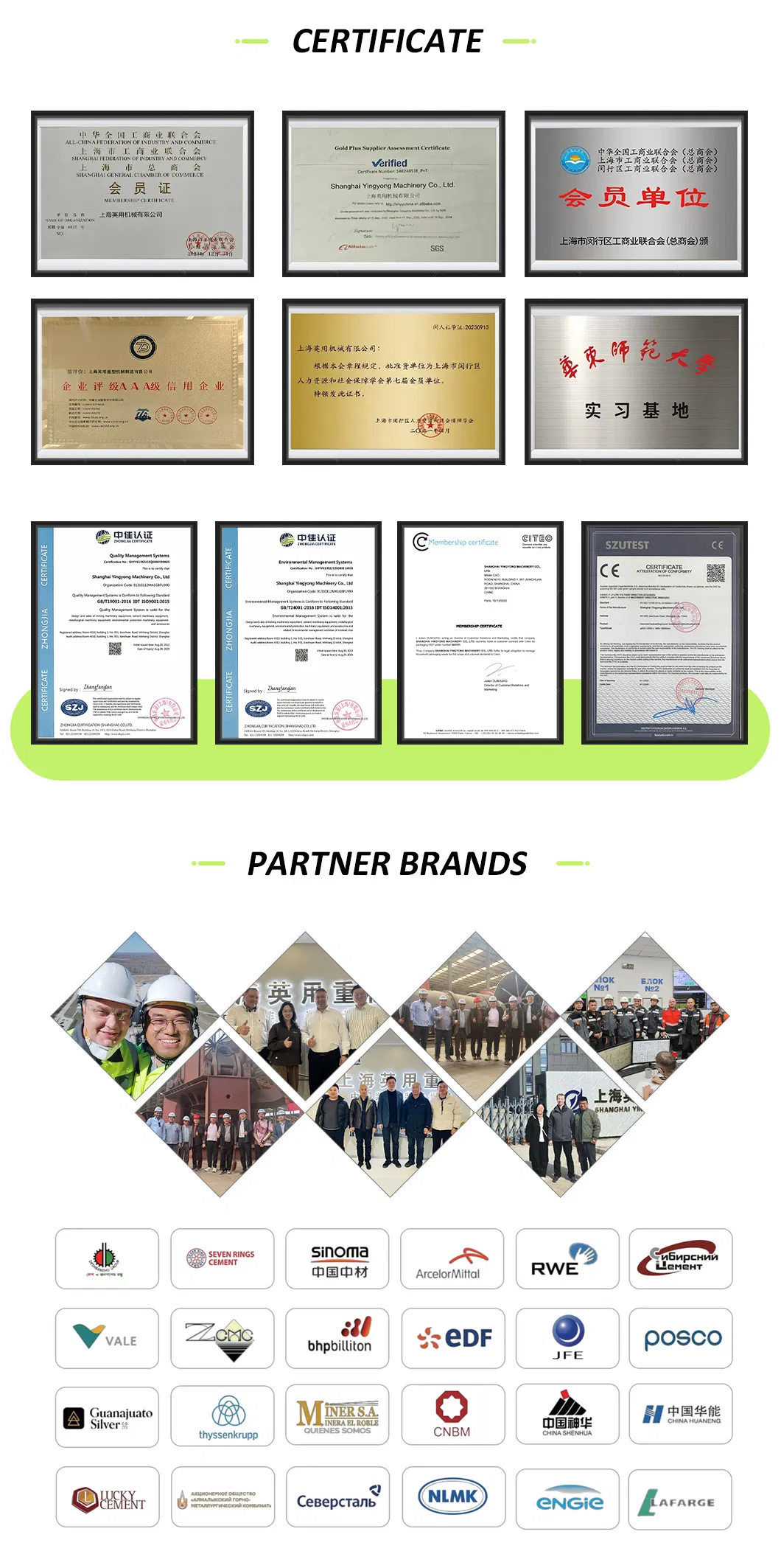

Certification: CE, ISO

Customized: Customized

Automatic Grade: Automatic

Advantage: High Heat Recovery

Color: Customized

Power: 800-20000kw

Factory Visit: Welcomed Warmly

Spare Parts: Supply All Using Life

Quality: High Level

Price: Negotiable

Video Outgoing-Inspection: Provided

Transport Package: Customized

Specification: 1000*1000*1000

Trademark: SYM

Origin: Shanghai

Production Capacity: 50000pieces/Year

Product Description

Grate Cooler

The Grate Cooler is a core equipment in cement production lines, designed for efficiently cooling clinker and recovering waste heat. Its modular grate bed ensures uniform clinker distribution and stable cooling while optimizing thermal efficiency and reducing energy consumption.

The Grate Cooler utilizes a multi-stage controlled grate bed to transport clinker, paired with high-pressure fans for zonal air supply, enabling rapid cooling and high heat recovery. Equipped with an intelligent control system, it dynamically adjusts air volume and grate speed to adapt to varying clinker sizes and production demands.

Grate Cooler Grate Plate

The grate plate is the core component of the grate cooler, directly handling high-temperature clinker for conveying and cooling. Made of high-chromium cast iron or heat-resistant steel, it offers exceptional wear resistance, high-temperature stability, and thermal shock resistance. Its unique design (e.g., fish-scale, stepped, or air-permeable structures) ensures even clinker distribution, enhances cooling air penetration, minimizes "red river" effects, and extends service life.

SYM Services

- One stop EPC service engineering procurement and construction

- On site installation and commissioning

- Technical training and operation guidance

- Spare parts support and after sales maintenance

Grate Cooler

- Modular Design: Sectional grate modules enable easy maintenance and capacity scaling.

- High Heat Recovery: Up to 75% waste heat reuse, drastically reducing energy loss.

- Zoned Air Supply: Multi-fan independent control for precise clinker cooling.

- Wear-Resistant Plates: High-chromium alloy resists heat/abrasion, 3x lifespan.

Application Fields

- Cement clinker cooling.

- Metallurgical sinter cooling.

- Thermal treatment of chemical raw materials.

- Solid waste processing.

Customization Options

- Grate Plate Options: Standard, fish-scale, or air-permeable designs for varied clinker properties.

- Enhanced Sealing: Reinforced side seals to minimize material leakage and dust.

- Smart Monitoring: Real-time temperature/pressure tracking with auto-adjustment.

- Drive Options: Variable frequency or fixed-speed motors for energy flexibility.

Why Choose SYM Machinery?

- Over 10 years of experience in rotary kiln manufacturing and design

- Strict quality control and international standard certifications

- Professional technical support and after-sales service

- Customized solutions to suit your raw materials and production capacity

FAQ

Frequently Asked Questions

- Q1: What production capacity can your grate cooler handle?

A1: Our coolers suit 1000-12000 TPD lines, with customizable designs. - Q2: What is the service life of the grate plates?

A2: High-chromium alloy plates last 3-5 years under standard conditions. - Q3: Can existing coolers be retrofitted?

A3: Yes, we offer modular upgrades for grates, fans, or control systems. - Q4: What is the heat recovery efficiency?

A4: Optimized design ensures secondary/tertiary air temperatures exceed 1000°C with ≥70% recovery.

${currentPro.title}