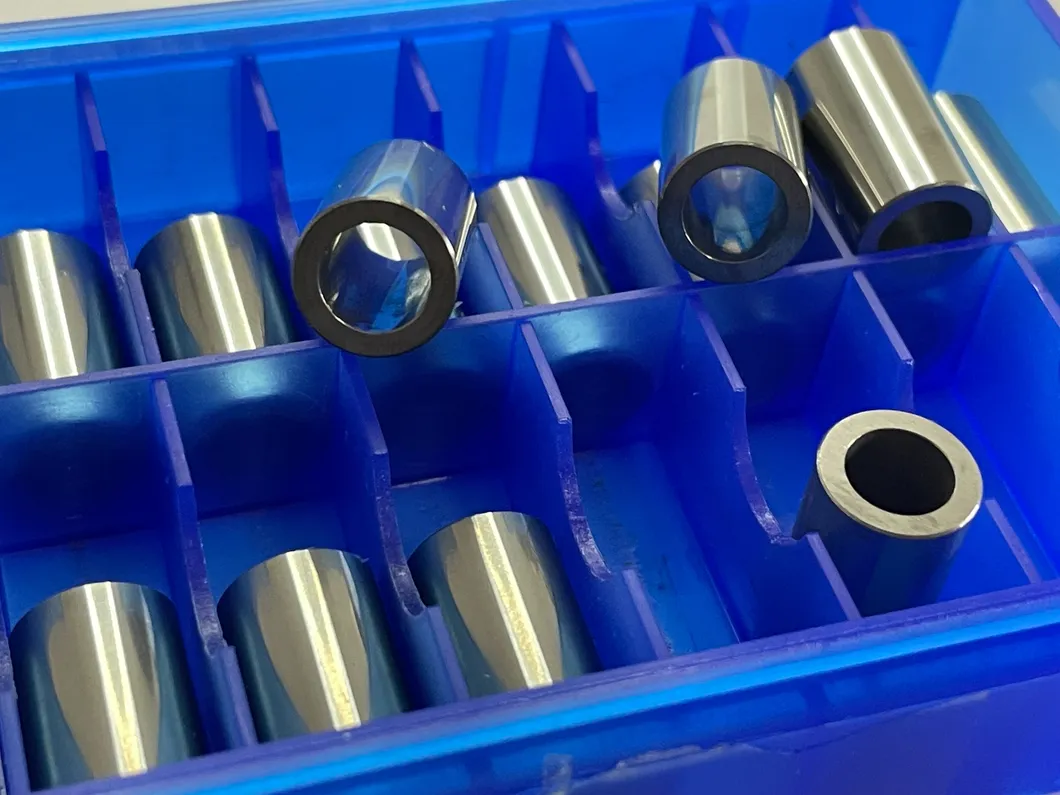

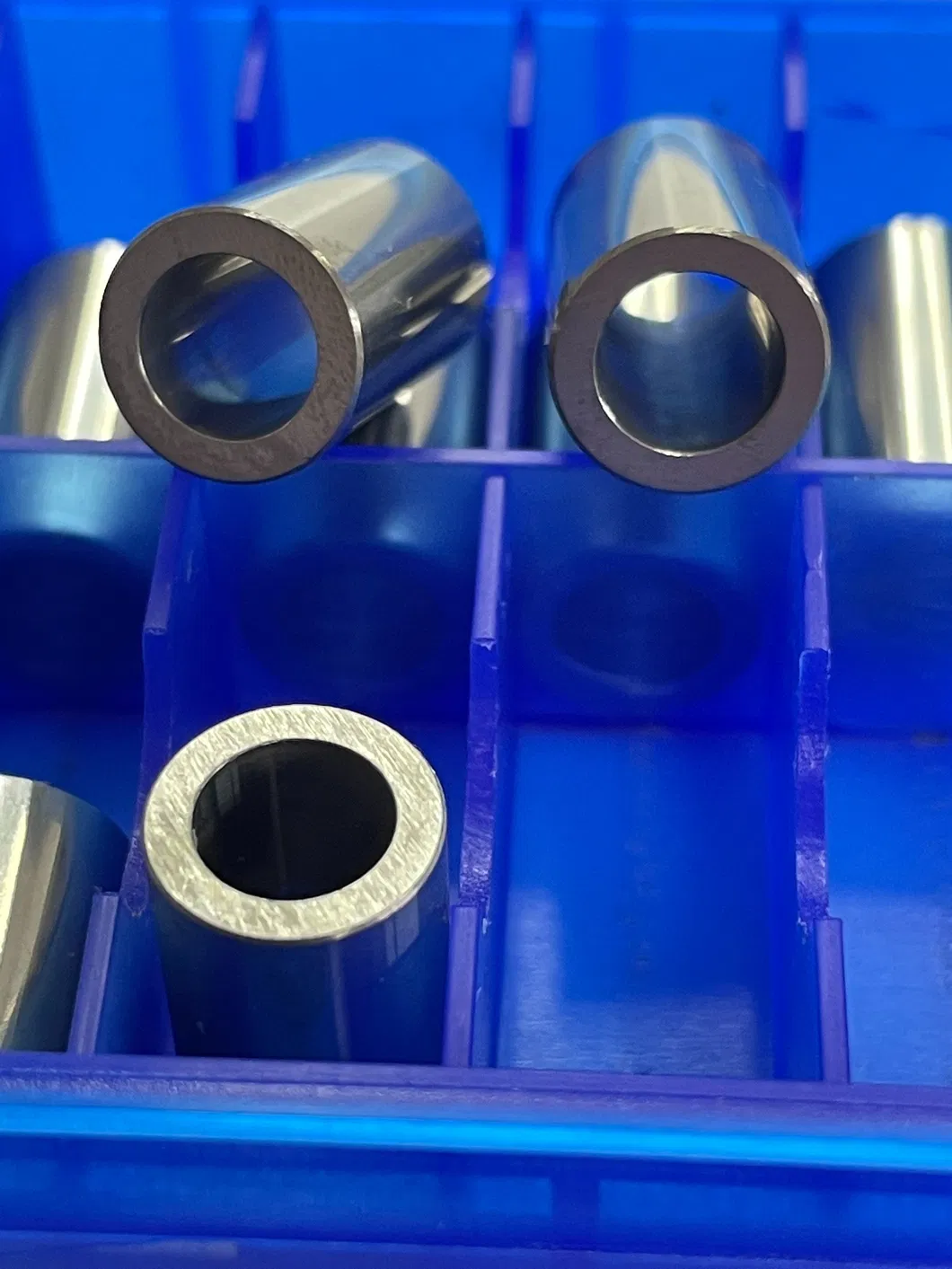

Fine Polished Tungsten Carbide Press-Fit Drill Bushings

Description

Overview

Basic Info.

| Model NO. | customized and standard |

| Manufacturing Process | Precise Drilling |

| Surface Treatment | Polishing |

| Operation Pressure | Atmospheric Pressure |

| Material | Carbide |

| Color | Dark Gray |

| Made of | Durable Tungsten Carbide |

| How to Use | Mount Flush with Jig Plates |

| Other Use | Shims/Spacers/Sleever |

| Tolerance ID | 0.0001" to 0.0005" |

| Tolerance OD | 0.0013" to 0.0018" |

| Tolerance L | -0.01" to 0.01" |

| Transport Package | by Carton |

| Specification | tungsten and coblat powder |

| Trademark | Evergreen or OEM |

| Origin | China |

| HS Code | 8209009000 |

| Production Capacity | 3 Tons/ Month |

Packaging & Delivery

| Package Size | 15.00cm * 10.00cm * 15.00cm |

| Package Gross Weight | 1.500kg |

Product Description

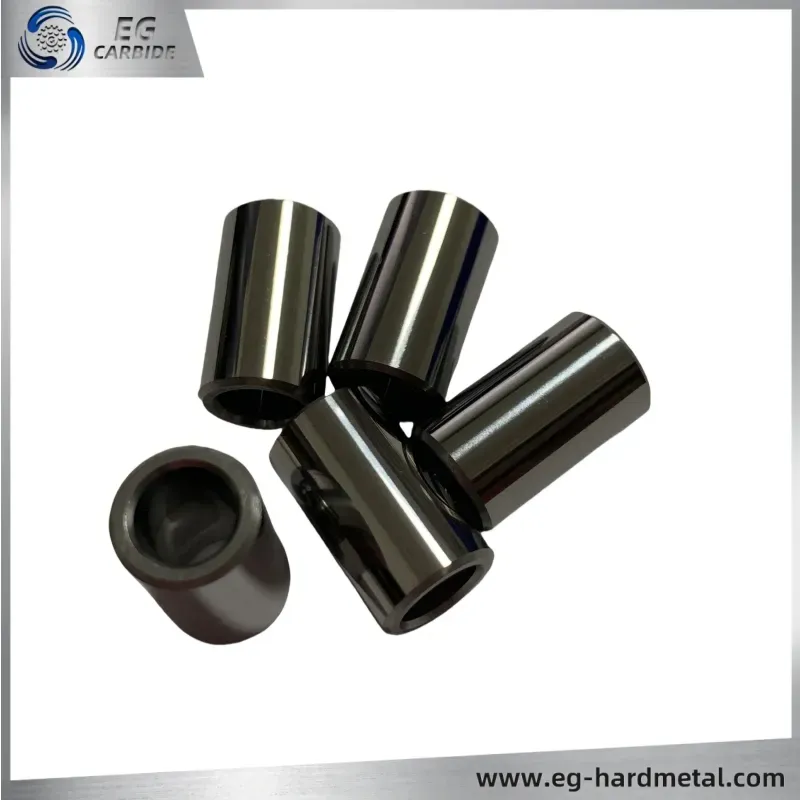

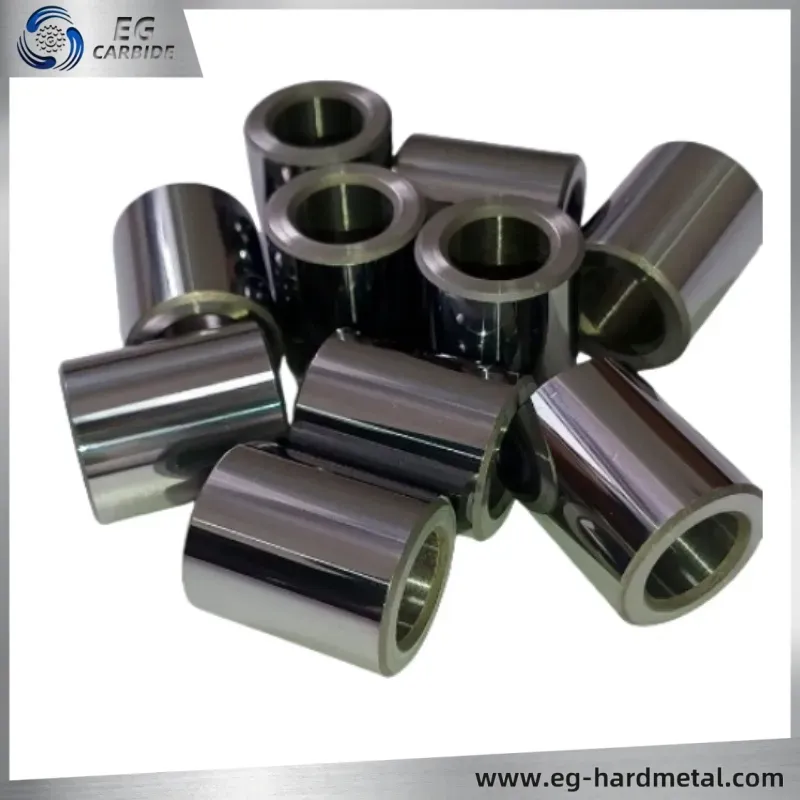

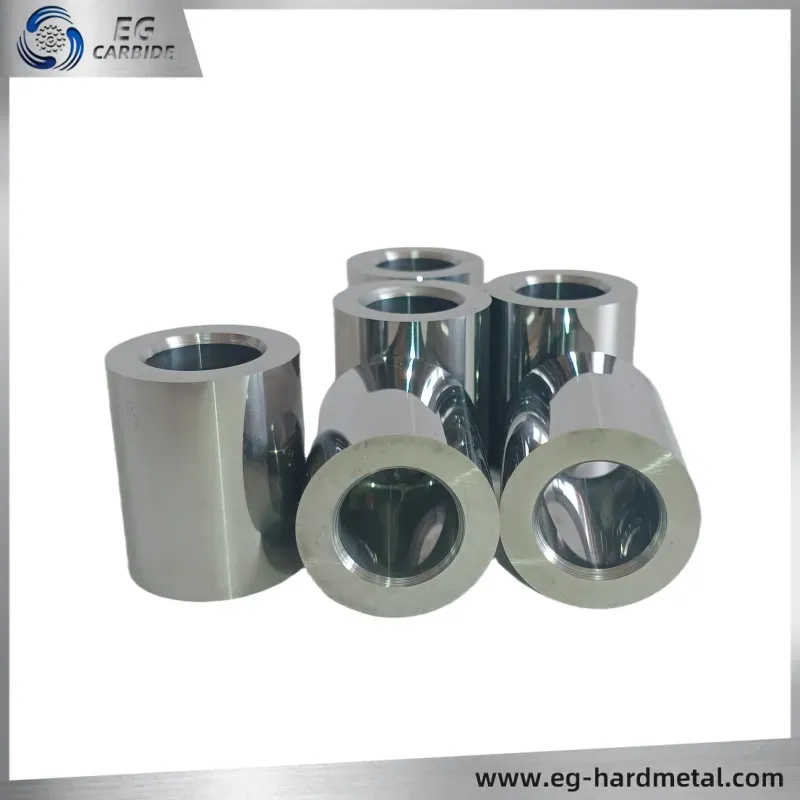

Products: Fine Polished Tungsten Carbide Wear Sleeve

Tungsten Carbide bushings are used as Mechanical Seal faces in pumps, Compressors and Agitators. These are used in Oil Refineries, Petrochemical plants, Fertilizer Plants, and Drugs/Pharmaceutical Industries.

Mechanical seal rings are developed to withstand high temperature, high pressure & highly corrosive chemical attack. We manufacture Rings in various shapes like Plain Ring, DA type, T-shape, L-shape and in shapes as per customers requirement.

Tungsten Carbide sleeve are generally made with Cobalt as binder material. Nickel bonded Rings also can be supplied.

Grade

| Grade | Binder (Wt%) | Density (g/cm3) | Hardness (HRA) | TRS (≥N/mm²) |

|---|---|---|---|---|

| YG6 | 6 | 14.8 | 90.0 | 1520 |

| YG6X | 6 | 14.9 | 91.0 | 1450 |

| YG6A | 6 | 14.9 | 92.0 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88.0 | 1810 |

| YG15 | 15 | 14.0 | 87.0 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84.0 | 2550 |

Applications

| Grade | Applications |

|---|---|

| YG6 | Good hardness and normal strength, for drawing of steel and non-ferrous metal and alloy bars or tubes under the condition of higher Stress. |

| YG6X | High wear resistance and high hardness, for drawing of steel wires and non-ferrous metal wires or alloy bars under low-stress condition. |

| YG8 | High wear resistance and high hardness, for drawing and straightening steels, non-ferrous metal and alloy bars and tubes; And for fabricating of machine parts, tools and wear parts, such as nozzles, centres, guiding devices, upsetting dies and perforating tools. |

| YG8X | Good strength and impact toughness; suitable for plates, bars, saws, seal rings, tubes etc. And it is one of the most popular grade for wear parts. |

| YG15 | High Strength and impact toughness, but lower hardness and wear resistance. For drawing steel rools and pipes under high stress condition; And also for upsetting dies and perforating tools under higher impact loading. |

| YG20 | Used as wear parts, sheets and some mechanical components. |

| EG10UF | Fine-grained alloy, good wear resistance and high strength. It is one of the most popular grade for rods, bars, tubes and other wear parts, which need high wear resistance and good cautery resistance and low impact toughness. |

| EG30UF | Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Suitable for rough machining of cast iron, non-ferrous metals, nonmetallic materials and heavy cutting. |

| YG6N | Good wear resistance and cautery resistance, high strength and fine impact toughness. Suitable for the submarine oil pump parts such as bushes and sleeves with excellent impact toughness. |

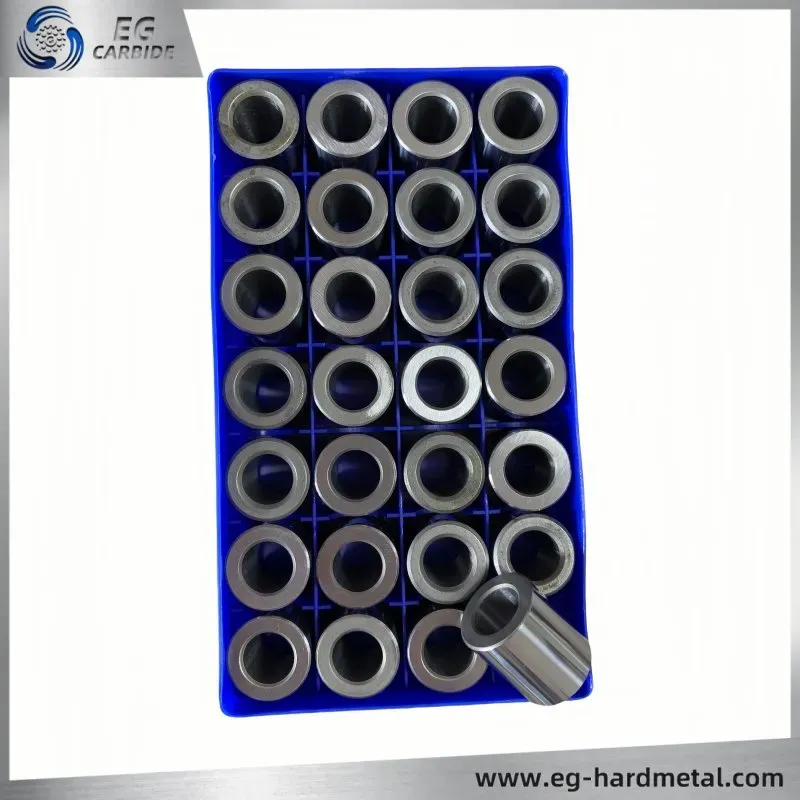

Detailed Photos

Please select specify ID, OD, and length.

| OD | Length | Material | Hardness |

|---|---|---|---|

| 0.0938 | 13/64" 1/2" 3/32" | Tungsten Carbide | ≥ hra89 |

| 0.125"ID | 1/4" 5/16" 1/8" | Tungsten Carbide | ≥ hra89 |

| 1/4" | 1/2" 1/8" | Tungsten Carbide | ≥ hra89 |

| 0.1875"ID | 5/16" 1/2" 3/16" | Tungsten Carbide | ≥ hra89 |

| 0.25"ID | 13/32" 1/2" 1/4", | Tungsten Carbide | ≥ hra89 |

| 1/2" | 1/2" 1/4", | Tungsten Carbide | ≥ hra89 |

| 0.3125"ID | 1/2" 1/2" 5/16" | Tungsten Carbide | ≥ hra89 |

| 1/2" | 1" 5/16" | Tungsten Carbide | ≥ hra89 |

| 5/8" | 3/4" 5/16" | Tungsten Carbide | ≥ hra89 |

| 0.5"ID | 3/4" 1/2" 1/2" | Tungsten Carbide | ≥ hra89 |

| 3/4" | 3/4" 1/2" | Tungsten Carbide | ≥ hra89 |

${currentPro.title}