EN

Language

All categories

Product ID: 66678509

FAW 4X2 Compressed Rubbish Truck

Contact Now

Description

Product description

性能和目的

Our company is a professional refuse compactor manufacturer in China. We have a perfect quality inspection system for refuse compactor. Supply ability of refuse compactor is 300 units per month. welcome to our company to purchase the refuse compactor.

Vehicle parameters

Vehicle Model HLW52501ZYSC Vehicle Brand FOMON

Overall dimensions 11500X2495X3345mm Curb weight 15650kg

Loading capacity 21m3

Vehicle Model HLW52501ZYSC Vehicle Brand FOMON

Overall dimensions 11500X2495X3345mm Curb weight 15650kg

Loading capacity 21m3

Chassis parameters

Chassis model CA5250XXYP63K2L5T1A1E Chassis brand FAW

Overall dimensions 10950x2495x2896mm Wheel base 5800+1350mm

Front/rear wheel track 1950, 1847/1847mm Front/rear suspension 1400/2900mm

Approach/departure angle 21/11° Maximum speed 90km/h

Chassis Manufacturer China FAW Group Corporation

Cab Configuration J6M full-fload high cab,allowable 3 passengers, electric lift glass, manual mirrors, air damping seats, automatic air conditioner, high efficiency single air filter, manual hydraulic lifting device.

Color White, other color is optional

Engine Model CA6DF3-26E3F

Emission Euro 3

Type 6 cylinders, in-line, 4-stroke, turbo inter-cooling, electronically controlled common rail, diesel engine

Rated power 260hp, rated power speed 2300rpm

Displacement 7120ml

Max.torque 930N.m

Bore x stroke 110X125mm

Manufacturer China FAW Group Corporation

Tire Size 11.00R20 steel wire tire

Number 10+1 nos

Clutch Φ 430 diaphragm clutch

Frame 270X75X(7+5)mm

Fuel tank 400L aluminum oil tank

Front axle 1950 front axle

Rear axle 457 axle, casting type, main reduction ratio 4.875

Drive form 6X4

Suspension Multi leaf springs

Rated voltage 24V,DC

Transmissions Shaanxi Fast Gear 8JS118, 8 speed forward 1 reverse.

Steering device Power assisted steering

Steering wheel Left hand drive

Selective configuration

If there is a slight change in the chassis parameters above, please take the actual product as the standard

Chassis model CA5250XXYP63K2L5T1A1E Chassis brand FAW

Overall dimensions 10950x2495x2896mm Wheel base 5800+1350mm

Front/rear wheel track 1950, 1847/1847mm Front/rear suspension 1400/2900mm

Approach/departure angle 21/11° Maximum speed 90km/h

Chassis Manufacturer China FAW Group Corporation

Cab Configuration J6M full-fload high cab,allowable 3 passengers, electric lift glass, manual mirrors, air damping seats, automatic air conditioner, high efficiency single air filter, manual hydraulic lifting device.

Color White, other color is optional

Engine Model CA6DF3-26E3F

Emission Euro 3

Type 6 cylinders, in-line, 4-stroke, turbo inter-cooling, electronically controlled common rail, diesel engine

Rated power 260hp, rated power speed 2300rpm

Displacement 7120ml

Max.torque 930N.m

Bore x stroke 110X125mm

Manufacturer China FAW Group Corporation

Tire Size 11.00R20 steel wire tire

Number 10+1 nos

Clutch Φ 430 diaphragm clutch

Frame 270X75X(7+5)mm

Fuel tank 400L aluminum oil tank

Front axle 1950 front axle

Rear axle 457 axle, casting type, main reduction ratio 4.875

Drive form 6X4

Suspension Multi leaf springs

Rated voltage 24V,DC

Transmissions Shaanxi Fast Gear 8JS118, 8 speed forward 1 reverse.

Steering device Power assisted steering

Steering wheel Left hand drive

Selective configuration

If there is a slight change in the chassis parameters above, please take the actual product as the standard

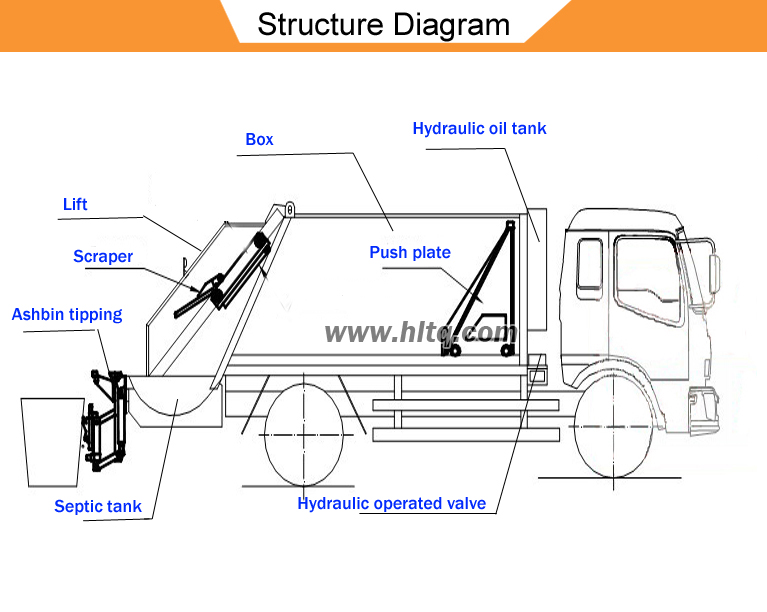

Refuse compactor structure parameters

Equipment

Structure Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems

Loading capacity 21m3

System of loading Mechanized, rear loading

Modes of the pressing Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic

Body

Version All-metal

Shape arc-shaped

Sidewalls Sheet carbon steel (thickness: 4 mm)

Bottom Sheet carbon steel (thickness: 5 mm)

Roof Sheet carbon steel (thickness: 4 mm)

Front frame Sheet carbonaceous steel (thickness: 5 mm)

Basis 120X120mm (thickness: 5 mm)

Loading bunker

Loading bunker All-metal with sidewalls and a loading ladle

Volume 1.5 m3

Sidewalls Sheet carbon steel (thickness: 4 mm)

Ladle floor material Sheet carbon steel (thickness: 5 mm)

Liquid drain Drainage channel,sewage tank

Working zone Lighting 2 lamps

Mechanism of raising Two hydraulic cylinders

Ensuring tightness Between the body and lifting back part in the lower part profile acid-proof rubber is used.

Pressing system

Features Control mode diversification,bidirectional compression

Pressure 16Mpa

Compaction ratio 3.0:1

Loading cycle 25-30 second

Unloading cycle 15-20 second

pressing mechanism The giving plate and hinge related pressing plate moving on two directing bars

Pressing mode Automatic pressing

(1 full cycle and continuous pressing) and controlling of each cycle of pressing separately

Control of pressing Control from the external panel on the bunker

Lifting rear part

Mechanism of lifting Two hydraulic cylinders

Function description Suitable for various rubbish bins

Others

Color and Logo Optional

Standard configuration Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control.

Selective configuration PLC electric automatic control,multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc.

Equipment

Structure Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems

Loading capacity 21m3

System of loading Mechanized, rear loading

Modes of the pressing Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic

Body

Version All-metal

Shape arc-shaped

Sidewalls Sheet carbon steel (thickness: 4 mm)

Bottom Sheet carbon steel (thickness: 5 mm)

Roof Sheet carbon steel (thickness: 4 mm)

Front frame Sheet carbonaceous steel (thickness: 5 mm)

Basis 120X120mm (thickness: 5 mm)

Loading bunker

Loading bunker All-metal with sidewalls and a loading ladle

Volume 1.5 m3

Sidewalls Sheet carbon steel (thickness: 4 mm)

Ladle floor material Sheet carbon steel (thickness: 5 mm)

Liquid drain Drainage channel,sewage tank

Working zone Lighting 2 lamps

Mechanism of raising Two hydraulic cylinders

Ensuring tightness Between the body and lifting back part in the lower part profile acid-proof rubber is used.

Pressing system

Features Control mode diversification,bidirectional compression

Pressure 16Mpa

Compaction ratio 3.0:1

Loading cycle 25-30 second

Unloading cycle 15-20 second

pressing mechanism The giving plate and hinge related pressing plate moving on two directing bars

Pressing mode Automatic pressing

(1 full cycle and continuous pressing) and controlling of each cycle of pressing separately

Control of pressing Control from the external panel on the bunker

Lifting rear part

Mechanism of lifting Two hydraulic cylinders

Function description Suitable for various rubbish bins

Others

Color and Logo Optional

Standard configuration Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control.

Selective configuration PLC electric automatic control,multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc.

Contact Now

Please Send Message

${currentPro.title}