cnc marking Angle punching machine with shearing function

Description

Product description

数控打标 带剪切功能的角度冲孔机

CNC Punching, Marking and Cutting Machine for Angles Model TAPM1010 is a CNC Angle Line Equipment. It mainly used for angle Punching, Marking and Cutting. It is wildly used in Communication Tower, power transmission tower and other industries.

This CNC angle line machine is a small model to process angle, the angle size is from 40*40*3mm-100*100*10mm. The material of the angle will be Q345. The punching force is 600/1000KN. There are two / Three punching head in each side of the CNC angle line machine.

There are totally three CNC axes for the angle processing machine. This angle line is single blade cutting (SCM also has double blade cutting angle line machine).

This kind of angle punching, marking and cutting machine can process max. length 10 or 12 meters raw angle. The max. length of finished angel is 8 m.

The layout of the CNC angle machine can be A type layout and B type layout. The customer can choose according with their workshop.

The machine is the special equipment used for angle steel punching, marking & shearing in the field of angle steel tower industry, mainly composed of transverse conveyor, rotating loading system, infeed conveyor, CNC infeed carriage, punching unit, marking unit, cutting unit, unloading conveyor, as well as hydraulic, electrical and pneumatic systems etc.

Product Feature:

1.采用数控技术,伺服电机进给,效率高,工件精度稳定。关键液压、气动和电气部件全部进口。2、每侧有三套冲头和模具,可安装三种不同直径的冲头,一次可加工所有孔。

3. 电脑具有中/英文界面,操作简单,可显示工件图纸。 编程简单,可以手动编程,也可以使用放样软件生成的程序。 我可以读取 TEKLA 软件生成的 NC.1 文件。

4. CNC 进给托架由伺服电机驱动。 光电编码器将信息反馈回来。 C失回路控制,确保高定位精度。

5. 自动完成打标、冲孔和剪切,所有成品角度都可以通过气动翻转装置卸载,以减轻工作强度。

6、控制系统由上位机、伺服电机、PLC、外部检查传感器等组成。只需输入工件的尺寸,即可进行加工。 此外,还可以根据工件编号存储、选择、显示和通信程序。

7. Marking 单元采用封闭框架,刚性好。 打版单元上固定了四组字符框,可通过程序进行选择。

8. TAPM2020A 刀片更换,无碎屑。 TAPM2020 TAPM2020C为增强型号,冲孔、打标和剪切气缸更大;

9. 具有避免剪切功能,以便处理定长角度。具有 故障自诊断功能。

Technical Parameter:

| Model | TBL2020 | TAPM2020 | TAPM2020A |

| Angle size (mm) | 50х50х3~200х200х20 | 63х63х4~200х200х20 | 63х63х4~200х200х20 |

| Max. Punching (dia. х thi.) (mm) | Φ26х20 | Φ26х20 | Φ26х20 |

| Punching force (kN) | 1000 | 1200 | 1200 |

| Marking force (kN) | 800 | 1030 | 1030 |

| Shearing force (kN) | 1400 | 2100 | 4300 |

| Max. length of blank (m) | 14 | 14 | 14 |

| Max. length of finished (m) | 12 | 12 | 12 |

| Punches per side | 3 | 3 | 3 |

| Group of Marking letters | 4 | 4 | 4 |

| Dimension of letter (mm) | 14×10×19 | 14×10×19 | 14×10×19 |

| CNC axes | 3 | 3 | 3 |

| Shearing mode | Double blade cutting | Double blade cutting | Single blade cutting |

| Feeding speed of angle (m/min) | 60 | 60 | 60 |

| Programming mode | Lofting software or instruction program | ||

| Overall dimensions (mm) | ≈32000×7000×3000 | ≈32000×7000×3000 | ≈32000×7500×3000 |

| Gross Weight of machine (kg) | ≈16500 | ≈17000 | ≈17500 |

| Total power (kW) | About 35 | About 40 | About 40 |

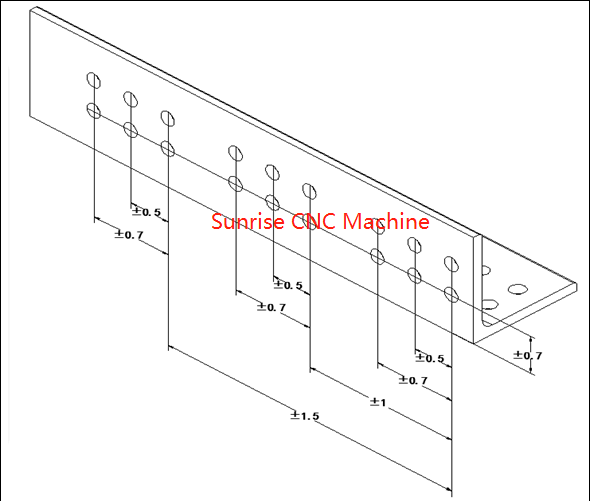

| Processing precision (The allowable tolerance): | ||

| 1. | Two adjacent hole deviation of the same group | ±0.5mm |

| 2. | Two not adjacent hole deviation of the same group | ±0.7mm |

| 3. | Hole deviation of two adjacent group | ±1mm |

| 4. | Stadia (Distance from central of hole to edge ) | ±0.7mm |

|

||

Main Components List:

| No. | Name | Brand | |

| Main Electric Components | |||

| 1 | PLC | Japan YOKOGAWA | |

| 2 | Servo Motor | Japan YASKAWA | |

| 3 | Servo Driver | ||

| 4 | Business Computer | China Lenovo | |

| 5 | Photoelectric Switch | AUTONICS | |

| 6 | Low-voltage electrical parts(Switches,Push button, Breaker,Indicator light, Contactor switch and so on) |

German SIEMENS | |

| 7 | Proximity Switch(N.O) | AUTONICS | |

| 8 | Proximity Switch(N.C) | AUTONICS | |

| 9 | Power Supply | China Aerospace | |

| Main Hydraulic Components | |||

| 1 | Hydraulic Valves | Italy ATOS | |

| 2 | Vane Pump | America DENISON | |

| Main Mechanical Components | |||

| 1 | Linear Slide | HIWIN | |

| 2 | Ball Screw | HIWIN | |

| Main Pneumatic Components | |||

| 1 | Punching Unit | Padding Block Cylinder | Japan SMC or AirTAC |

| 2 | Magnetic Switch | Japan SMC or AirTAC | |

Spare parts list:

| No | Name | Material | Qty. | Remark |

| 1 | Punch head (Ф17.6, Ф21.6, Ф25.6) | T10A | 12 | Including installed in machine |

| 2 | Cavity die (Ф18.7,Ф19.2,Ф22.7, Ф24.6,Ф26.7,Ф28.6) | T10A | 24 | Including installed in machine |

| 3 | Upper blade | 9CrSi | 2 | Including installed in machine |

| 4 | Short nether blade | 9CrSi | 4 | Including installed in machine |

| 5 | Long nether blade | 9CrSi | 4 | Including installed in machine |

| 6 | Punching die base | ZG45 | 7 | Including installed in machine |

| 7 | Punch head pole | T10A | 7 | Including installed in machine |

| 8 | Punching screw nut | 40Cr | 7 | Including installed in machine |

| 9 | Upper jaw | T10A | 2 | Including installed in machine |

| 10 | Nether jaw | T10A | 2 | Including installed in machine |

| 11 | Character box | T10A | 4 | Including installed in machine |

| 12 | Character | T10A | 1 set | Including installed in machine |

| 13 | Proximity switch | Normal open | 1 | AUTONICS |

| 14 | Proximity switch | Normal close | 1 | AUTONICS |

| 15 | Photoelectric switch | 1 | AUTONICS | |

| 16 | Charge nitrogen tool | CQJ-16 | 1 set | |

| 17 | O ring | 2 sets | ||

| 18 | Spanner for punch head | 1 | Manufacturer made | |

| 19 | Spanner | 2 | Manufacturer made | |

| 20 | Tools with equipment | 1 set | ||

| 21 | Springs | 1 set | ||

| 22 | Standby paint | 2 pail | 1pail for main color and 1pail for warning color | |

| 23 | Operation Manual & Attached Illustration | 2 sets | ||

${currentPro.title}