EN

Language

All categories

Product ID: 66926095

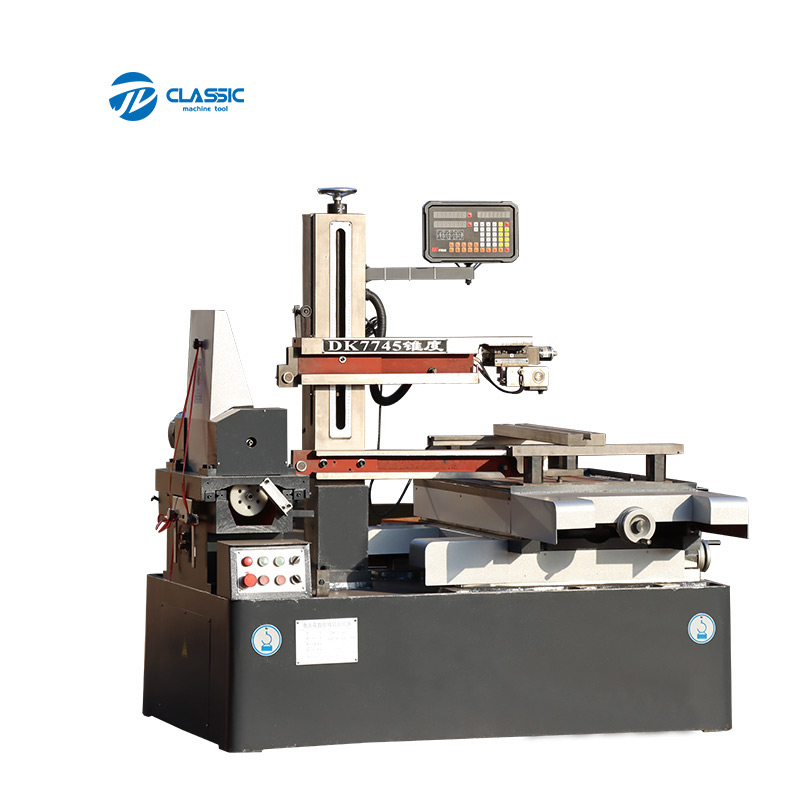

Hot Sale Edm Wire Cutting Machine with 0.18mm Molybdenum Wire DK7745

Contact Now

Description

产品描述

Products Description

Product Application

Our company produces DK77 series wire EDM machines, models are complete, structure is reasonable, rigidity is good, and precision

is high. High-grade machine adopts precision linear guide rail, and high column optionally equips electric lifting roller span

adjustment. Swinging big taper series machine tools are equipped with wire electrode wire agencies, and produce semi-hermetic

environmental protection machine tools. Molybdenum wire diameter range is from 0.12-0.18mm, maximum processing speed is more than

120 mm² / min, the best surface roughness ≤Ra2.5um(single cut)Ra1.6mm(multicut).

is high. High-grade machine adopts precision linear guide rail, and high column optionally equips electric lifting roller span

adjustment. Swinging big taper series machine tools are equipped with wire electrode wire agencies, and produce semi-hermetic

environmental protection machine tools. Molybdenum wire diameter range is from 0.12-0.18mm, maximum processing speed is more than

120 mm² / min, the best surface roughness ≤Ra2.5um(single cut)Ra1.6mm(multicut).

|

Machine model

|

DK7745

|

|

Weight

|

1800 kg

|

|

Dimension (L*W*H)

|

1700*1400*1600

|

|

Worktable size(mm)

|

800*460

|

|

Travel size (mm)

|

600*400

|

|

Max Workpiece Thichness (mm)adjustable

|

400

|

|

Max workpiece weight(kg)

|

450

|

|

Max Productivity(mm²/min)

|

≥150mm²/min

|

|

Best surface roughness(Ra)

|

Ra≤2.5μm

|

|

Wrie diameter(mm)

|

0.1-0.25mm

|

|

Taper angle

|

6°/80mm-12°/80mm

|

|

Accuracy(mm)

|

≤±0.015mm

|

|

Power supply

|

380V/50HZ

|

1.BMXP software Functions:

(1)Coordinate system: Absolute coordinate, incremental coordinate (relative coordinate)

(2)Functions of coordinate transforming, zooming in and zooming out, rotating and tracking display in real time (3)Functions of interpolation of straight line and circular arc

(4)Function of taper processing

(5)Function of processing different top and bottom abnormities parts

(6)Auto-handle for short circuit and wire-break

(7)Functions of memorizing when power was cut and auto-stop after processing

(8)Functions of auto edge-touching position and auto center finding

(8)Functions of auto edge-touching position and auto center finding

(9)Function of auto-adding transitional arc (Arbitrary angle)

(10)Function o Functions of menu technology and auto-programming ward

(10)Function o Functions of menu technology and auto-programming ward

(11)Functions of menu technology and auto-programming

(12)AUTOCAD can be used to program directly in the software.

(12)AUTOCAD can be used to program directly in the software.

2. CNC system configuration and technical performances

(1) CNC Hardware configuration:

(A) Industrial Computer: P4 or above

(B)EMS memory: 1G

(C)Fixed DisK: 160G

(D)USD and Internet

(E)15"liquid crystal display (LCD)

(F) RS232 and Keyboard and mouse

3. Axis processing

(1)CNC technical function:

(2)Running environment

(A)Temperature: 5-40 degree

(A)Temperature: 5-40 degree

Relative humidity: 40%~80%

Detailed Images

Contact Now

Please Send Message

${currentPro.title}