steel rebar cage making machine

Description

Product description

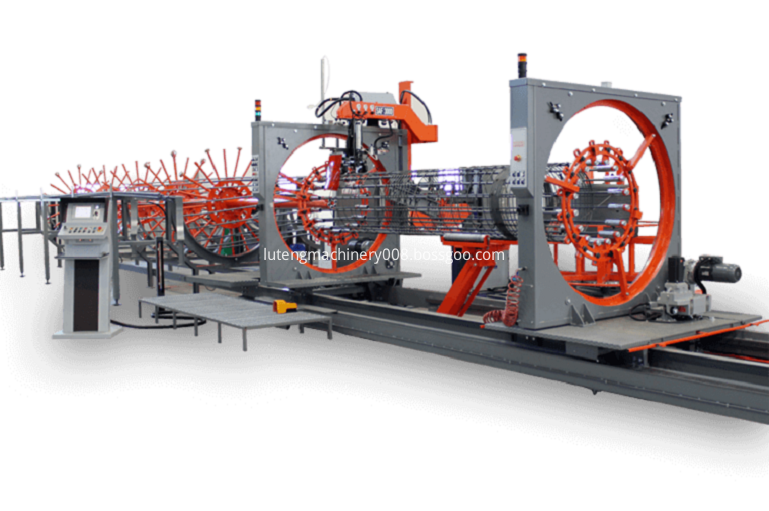

steel rebar cage making machine

Product Description

|

Model |

|

|

|

|

Cage diameter(mm) |

Φ500-1500 |

Φ500-2000 |

Φ500-2500 |

|

Cage length(m) |

2-12 |

2-12 |

2-12 |

|

Max Weight of reinforcement cages(KG) |

≤4500 |

≤6000 |

≤8000 |

|

Diameter of main bar(mm) |

Φ16-32 |

Φ16-32 |

Φ16-32 |

|

Spiral diameter(mm) |

Φ6-12 |

Φ6-12 |

Φ6-12 |

|

Spiral spacing(mm) |

50-500 |

50-500 |

50-500 |

|

Labeled electric power(kw) |

18 |

21 |

25 |

|

Walking speed(m/min) |

1.5 |

1.5 |

1.5 |

|

Rotating speed(r/min) |

2-4 |

2-4 |

2-4 |

|

Over Dimension(L*W*H)(mm) |

27000×4500×2700 |

27000×5000×3200 |

27000×5500×3700 |

Production Process

Feeding → Inserting rebar(main bar) → fixing →overlapping stirrup→start welding → normal welding→ stop welding → cutting stirrup → Separate fixed disk → loosing rebar →separating movable disk → unloading cage→ lowering electric support → resetting movable disk

Production efficiency

1500mm pile cage: two classes, can process 300-400 meters /day,( 68118692, 56998586, 56998330,about 20 tons).

When Welding a 12-metre steel cage, the general loading and unloading time is approximately 15-20 minutes, normal welding time is approximately 18-25 minutes (spacing 120mm), so the comprehensive time is 30-45 minutes, the speed can be greatly improved after skilled.(generally, the weight of a steel cage with diameter of 1.5 meters and length of 12 meters is about 800 kg)

The efficiency of making pile cage is related to the quantity of the longitudinal rebars, the diameter of the cage, the coil spacing and the skill of workers.

Steel cage template

According to actual requirements, the design of pile cage will be different (such as the quantity or diameter of longitudinal rebar), it`s adaptable to different engineering needs by changing the template and the catheter.

Product display

Packaging & Shipping

|

Packaging Details: |

Wooden case or as the client's requests |

|

Delivery Detail: |

Within 15days after receiving your deposit. |

Our Services

Pre-sale Service

1. Supply item design, process design.

2. Help you choose a proper machine.

3. Making the machine according to your requirement.

Sale Service

1. Acceptance equipment together with you.

2.Help you to make the method statement and the details of process.

After-sales Service

1. Guarantee for a year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life.

Company Information

${currentPro.title}