EN

Language

All categories

Product ID: 68156337

High Efficiency Hydrothermal Carbonization and Pyrolysis Search Engine

Contact Now

Description

Product description

Products Description

The smokeless continuous carbonization furnace consists of a conveyor, a high-temperature furnace, dust removal, decoking, purification, a gas cabinet, a power distribution cabinet and other equipment. It is the latest developed continuous carbonization equipment that is efficient, environmentally friendly and intelligent.

This equipment is the latest carbonization equipment in China that integrates the co-production of "carbon, gas, oil and

fertilizer". It can carbonize a variety of materials, such as straw, branches, wood chips, fungus materials, etc. It has no strict requirements on the materials and can be directly carbonized without crushing. It also realizes production processes such as continuous feeding, continuous carbonization, layered carbonization, intelligent control, automatic collection of tar and combustible gas, thereby improving the quality of carbon powder, solving the various drawbacks of traditional carbonization production such as low efficiency and high labor intensity, and truly realizing the efficient and rational utilization of renewable resources.

This equipment is the latest carbonization equipment in China that integrates the co-production of "carbon, gas, oil and

fertilizer". It can carbonize a variety of materials, such as straw, branches, wood chips, fungus materials, etc. It has no strict requirements on the materials and can be directly carbonized without crushing. It also realizes production processes such as continuous feeding, continuous carbonization, layered carbonization, intelligent control, automatic collection of tar and combustible gas, thereby improving the quality of carbon powder, solving the various drawbacks of traditional carbonization production such as low efficiency and high labor intensity, and truly realizing the efficient and rational utilization of renewable resources.

Technical Parameters

The carbonization process in a Biochar kiln can generally be divided into the following three temperature stages:

Drying Stage: From ignition to the furnace temperature reaching 160°C, the moisture content in the briquettes relies mainly on external heating and heat generated from their own combustion for evaporation. The chemical composition of the briquettes remains largely unchanged during this stage.

Initial Carbonization Stage: This stage is driven primarily by the combustion of the briquettes themselves, raising the furnace temperature to between 160°C and 280°C. At this point, thermal decomposition reactions occur in the woody material, leading to changes in its composition. Unstable components such as hemicellulose undergo decomposition, producing substances like CO2, CO, and small amounts of acetic acid.

Full Carbonization Stage: This stage occurs within the temperature range of 300°C to 650°C.During this stage, the woody material undergoes rapid thermal decomposition, simultaneously generating significant amounts of liquid products such as acetic acid, methanol, and wood tar. Additionally, combustible gases like methane and ethylene are produced. These gases can be controlled and utilized through valves for cyclic combustion. The combined processes of thermal decomposition and gas combustion generate a substantial amount of heat, raising the furnace temperature. The woody material is distilled into charcoal under high temperatures.

For the production of high-temperature charcoal, apart from the three stages mentioned above, additional heat is applied to raise the furnace temperature further to around 800°C to 1000°C. This helps to expel volatile substances remaining in the charcoal, increase the carbon content, enhance the graphite structure within the charcoal, and improve its conductivity.

Drying Stage: From ignition to the furnace temperature reaching 160°C, the moisture content in the briquettes relies mainly on external heating and heat generated from their own combustion for evaporation. The chemical composition of the briquettes remains largely unchanged during this stage.

Initial Carbonization Stage: This stage is driven primarily by the combustion of the briquettes themselves, raising the furnace temperature to between 160°C and 280°C. At this point, thermal decomposition reactions occur in the woody material, leading to changes in its composition. Unstable components such as hemicellulose undergo decomposition, producing substances like CO2, CO, and small amounts of acetic acid.

Full Carbonization Stage: This stage occurs within the temperature range of 300°C to 650°C.During this stage, the woody material undergoes rapid thermal decomposition, simultaneously generating significant amounts of liquid products such as acetic acid, methanol, and wood tar. Additionally, combustible gases like methane and ethylene are produced. These gases can be controlled and utilized through valves for cyclic combustion. The combined processes of thermal decomposition and gas combustion generate a substantial amount of heat, raising the furnace temperature. The woody material is distilled into charcoal under high temperatures.

For the production of high-temperature charcoal, apart from the three stages mentioned above, additional heat is applied to raise the furnace temperature further to around 800°C to 1000°C. This helps to expel volatile substances remaining in the charcoal, increase the carbon content, enhance the graphite structure within the charcoal, and improve its conductivity.

|

Model

|

800

|

1000

|

1200

|

1500

|

1800

|

2000

|

|||||

|

Number of cylinder layers

|

Single

|

Single

|

Double

|

Double

|

Double

|

Double

|

|||||

|

Cylinder diameter

|

800mm

|

1000mm

|

1200/700mm

|

1500/900mm

|

1800/1200mm

|

2000/1500mm

|

|||||

|

Capacity

|

200-300kg/h

|

300-400kg/h

|

450-600kg/h

|

600-800kg/h

|

800-1000kg/h

|

1000-1200kg/h

|

|||||

|

Cylinder material

|

309S/310S/316L

|

309S/310S/316L

|

309S/310S/316L

|

309S/310S/316L

|

309S/310S/316L

|

309S/310S/316L

|

|||||

|

Power

|

1.5kw

|

2.2kw

|

5.5kw

|

7.5kw

|

11kw

|

15kw

|

|||||

|

Temerature

|

500-800ºC

|

|

|

|

|

|

|||||

|

Carbonization time

|

20-60min

|

|

|

|

|

|

|||||

|

Raw material particle size

|

≤4cm

|

|

|

|

|

|

|||||

|

Heating method

|

indirect heating

|

|

|

|

|

|

|||||

|

Operation mode

|

continuously working

|

|

|

|

|

|

|||||

|

Control method

|

PLC control

|

|

|

|

|

|

|||||

|

Induced draft fan power

|

1.5kw

|

2.2kw

|

7.5kw

|

11kw

|

18.5kw

|

22kw

|

|||||

|

Preheat burner model

|

10kcal×3

|

10kcal×4

|

15kcal×4

|

20kcal×4

|

30kcal×4

|

30kcal×6

|

|||||

|

Preheat burner fuel

|

Fuel oil/gas/biomass/coal gas/biomass synthesis gas

|

|

|

|

|

|

|||||

The professional experimental testing team can provide experiments and testing of various key data such as fixed carbon contentand ash content. Provide you with reliable solutions.

Product Application

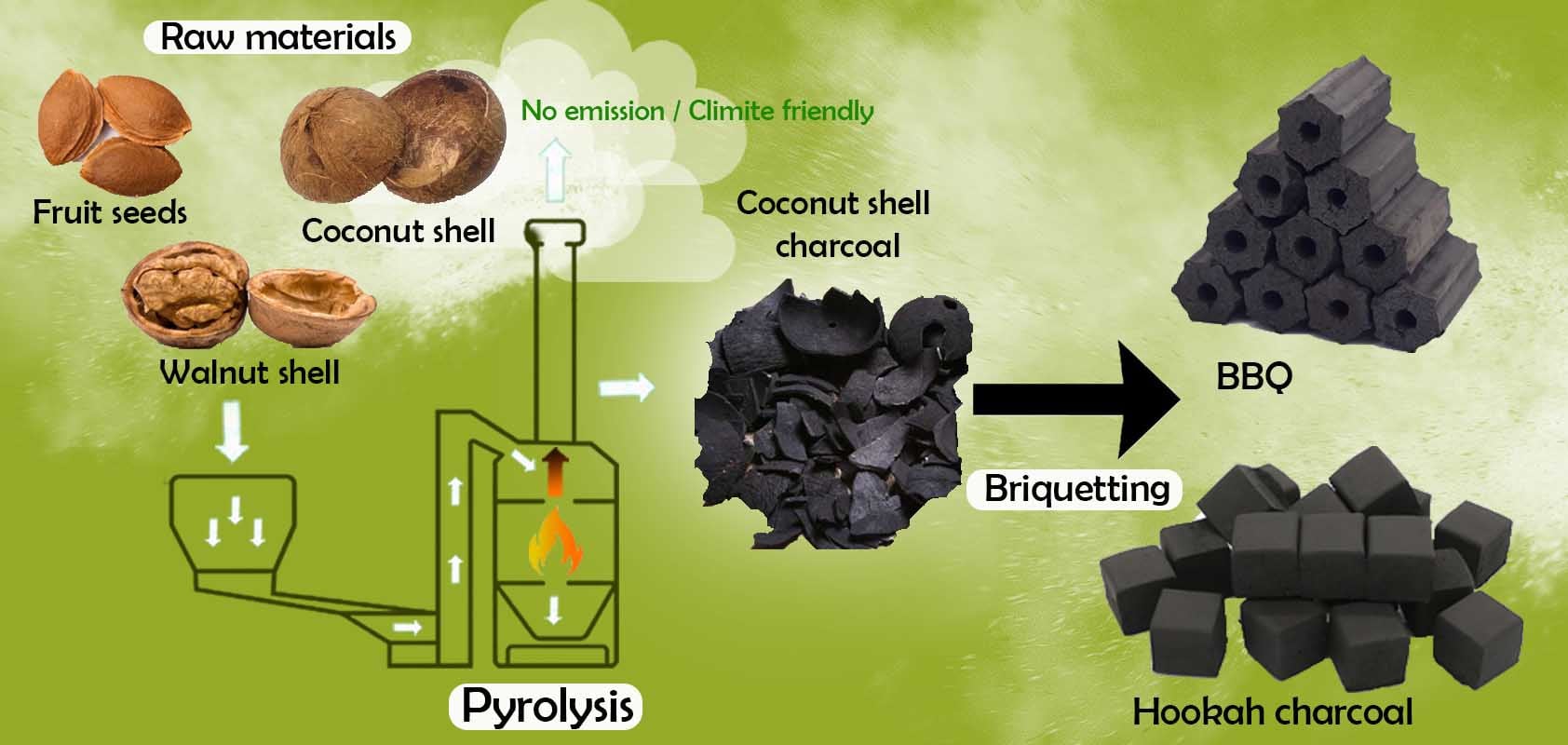

Raw materials

seeds; shells and pits of tree-fruits; wood chips; bamboo; shrubby and other plant materials, the fraction of which is from 5 to 30 mm with a moisture content of not more than 15%.

|

Coconut shell

|

Walnut shell

|

Hazelnut shell

|

Wood chips

|

Bamboo

|

|

Coconut shell charcoal

|

Shell charcoal

walnut

|

Hazelnut shell charcoal

|

Wood chips charcoal

|

Bamboo charcoal

|

|

Palm kernel shell

|

Pits of olives

|

Pits of date

|

Peach Shell

|

Hawthorn Seed

|

|

Palm kernel charcoal

|

Pits of olives charcoal

|

Pits of date charcoal

|

Peach Shell charcoal

|

Hawthorn Seed charcoal

|

Received products

Raw materials for obtaining activated carbon Raw Material for BBQ Charcoal Briquette and Industry Raw materials for the production of coal briquettes for hookahs (hookah, hookah coal)

BIO-Char, as a fertilizer or hydroponic growth intended for the agricultural industry, is made from plant raw materials and does not contain harmful substances.

Brief description of the production process

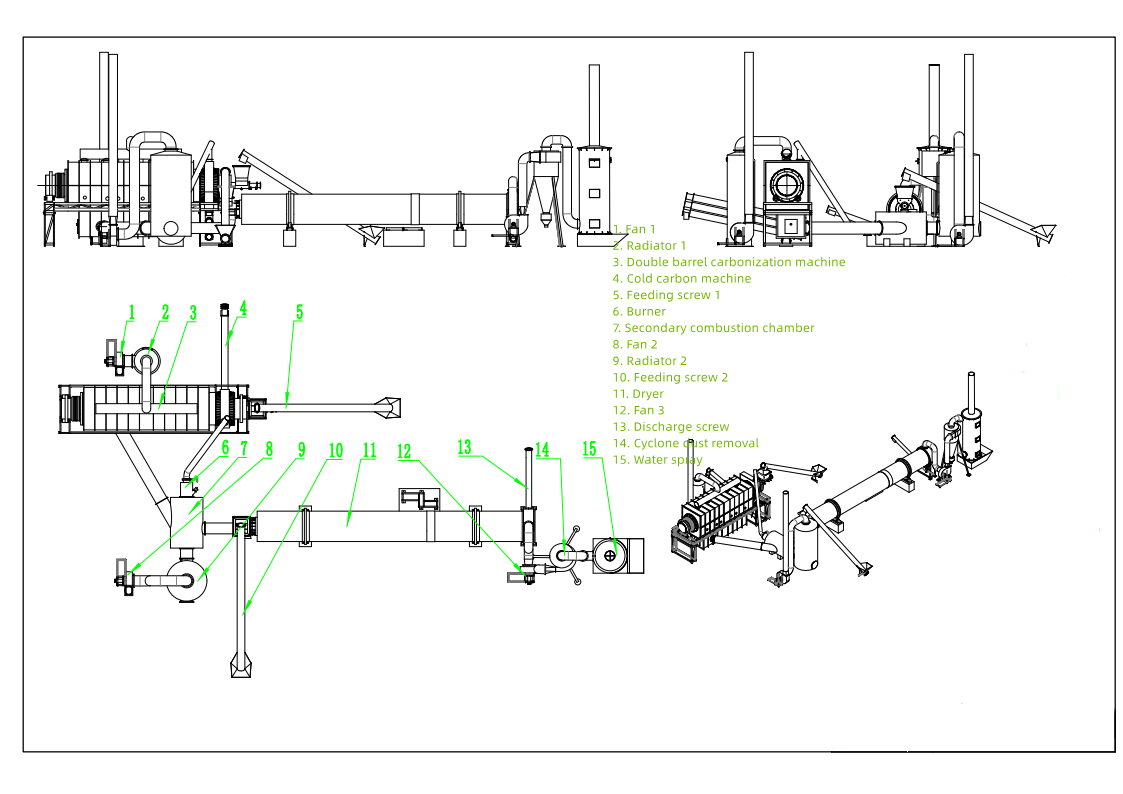

Biomass Pyrolysis Equipment Continuous Carbonization Furnace for Sawdust, Coconut Shell, Bagasse, Olive Pomace, Rice Husk, Palm, The machine is equipped with: crushing system, drying system, liquefied gas combustion system, flue gas purifier, fan, self-distributing gas burner, dry distillation carbonization furnace, secondary combustion chamber, grinding system, environmental protection carbon rod production and other equipment ( See attached image for details). This system is energy-saving, environmentally friendly, dust-free, smoke-free and tasteless. The direct-fired type does not produce wood tar and wood vinegar. It adopts the double-drum dry distillation and carbonization method to make full use of the combustible gases such as carbon monoxide, methane, and hydrogen generated in the carbonization process. The gas purification system separates dust (the dust will enter the cold carbon machine with the cold carbon equipment) and pure combustible gas, and then fully burns through the self-distributing air burner to heat the high temperature carbonization equipment (the temperature is generally controlled at about 700-800 ℃ ). There are double sleeve pipes inside the carbonization machine, the inner barrel is a preheating and drying pipe, and the outer barrel is a high temperature carbonization pipe. The inner cylinder pipe uses the waste heat in the furnace to dry the material, and the outer cylinder is provided with a combustible gas recovery pipe. The combustion of the burner heats the pipeline, and the mixed gas collected from the carbonization equipment enters the filter system from the lower part, and the filtered pure gas is recycled to the combustion chamber heating equipment to achieve the effect of reciprocating cycle heating and carbonization. The primary carbonization ignition gas source is supplied by the liquefied gas combustion system.

Baoyuan Machinery is a comprehensive enterprise that comprises R& D, test, manufacture, sales and service functions. We have succeeded in researching and supplying solutions with the following equipment: Drying equipment, activated carbon production equipment, building materials equipment, beneficiation equipment, crushing equipment and other products.

With our leading-edge technologies, advanced processing equipment and our corporate spirit of "innovation, pragmatism, unity, hard work and dedication", our company has the strength to meet the challenges from all aspects. We have the confidence to build "Baoyuan" into a world-renowned brand, provide quality services for the dryer and building processing industry, and achieve a win-win situation between the company and customers.

With our leading-edge technologies, advanced processing equipment and our corporate spirit of "innovation, pragmatism, unity, hard work and dedication", our company has the strength to meet the challenges from all aspects. We have the confidence to build "Baoyuan" into a world-renowned brand, provide quality services for the dryer and building processing industry, and achieve a win-win situation between the company and customers.

Contact Now

Please Send Message

${currentPro.title}