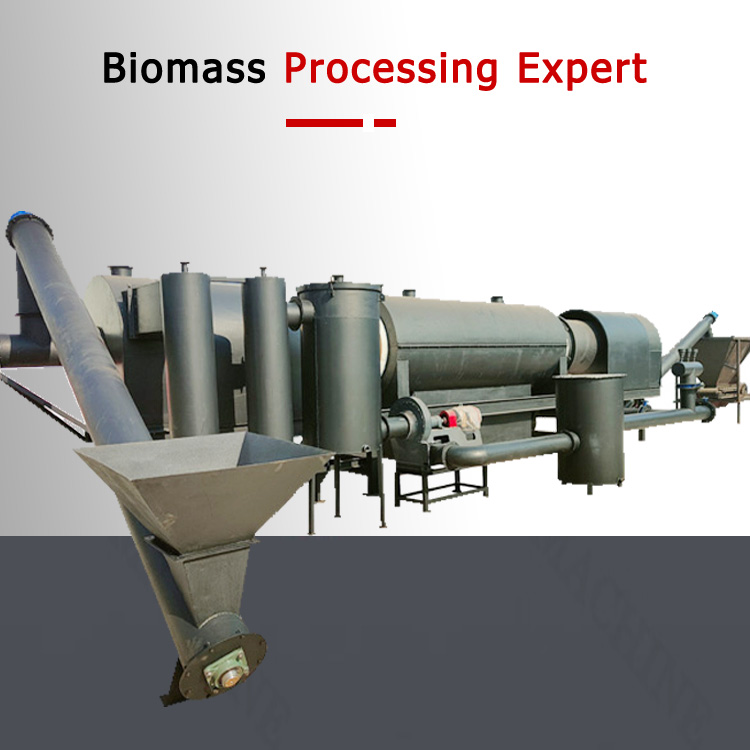

High Quality Wood Waste and Rice Husk Biochar Pyrolysis Kilns and Carbonization Furnaces

Description

Product description

The continuous carbonization furnace is mainly used for the carbonization of biomass materials. The equipment is still using the principle of gasification carbonization and adopts advanced smoke-free environmental carbonization process:The whole set of equipment consists of gasification system (liquefied gas gasification machine), purification system (spray tower, cyclone dust removal, water cooling, oil water separator, fine filter) and control system (control cabinet). The whole carbonization process is automated production, automated operation.

Different from the energy-saving and environmentally-friendly continuous carbonization machine, it has two significant advantages: First, the main machine has a large volume, high carbonization rate, and strong production capacity, and can be produce 0.3-0.8 tons of carbonized products per hour;

Second, the cost is low and the practicability is strong, which satisfies the objective requirements of the initial small entrepreneurs' investment and small benefits. The carbonization machine is a carbonized wood material such as wood chips, rice husks, peanut shells, plant straws, bamboo chips, coconut shells, palm shells, bark, etc. (volumes of less than 10 cm in size) are subjected to dry distillation under high temperature conditions in the furnace, Ideal equipment for oxygenation and high carbonization rates.

|

Model

|

LXT-1000

|

LXT-1200

|

|

|

Feed power

|

3kw+1.1kw

|

3kw+2.2kw

|

|

|

Cooling and discharge power

|

3kw+3kw

|

3kw+3kw

|

|

|

Drive motor

|

5.5kw

|

7.5kw

|

|

|

Fan motor

|

7.5kw

|

11kw

|

|

|

Diameter*length

|

1m*12m

|

1.2m*12m

|

|

|

Output capacity

|

600-800kg/h

|

800-1200kg/h

|

|

|

Working continuously

|

24H

|

|

|

|

The feed temperature

|

350-450℃

|

|

|

|

The raw material size

|

≤3cm

|

|

|

|

The raw material moisture

|

≤15%

|

|

|

According to this method of circulation, sufficient to achieve self-sufficient, then achieve the effect of energy-saving.The flue gas through purification, to reach the environment production and flue gas emissions-free. Which is reached to the standards of waste gas emptying. The whole carbonization process is automated production, automated operation.

${currentPro.title}