Global Fastener Solutions

Description

Overview

Basic Info.

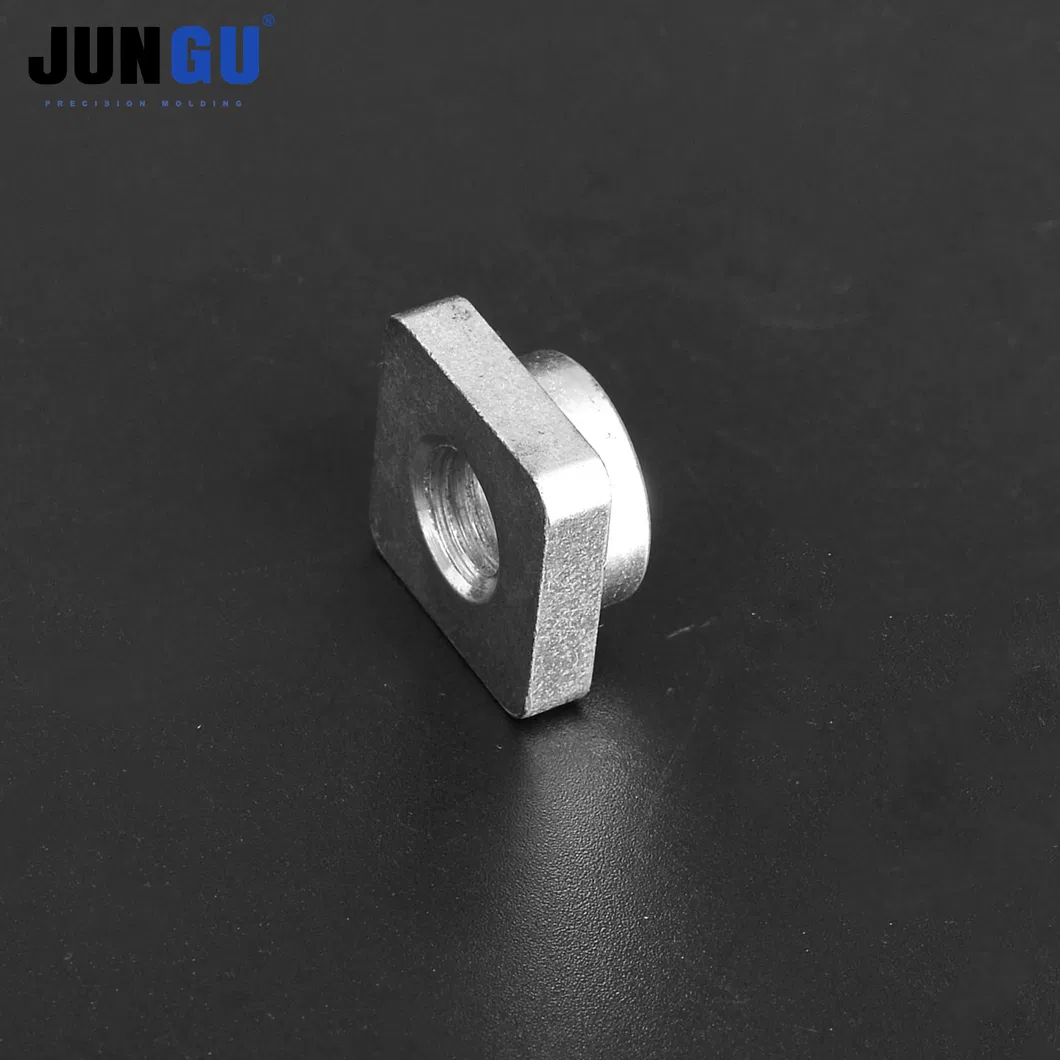

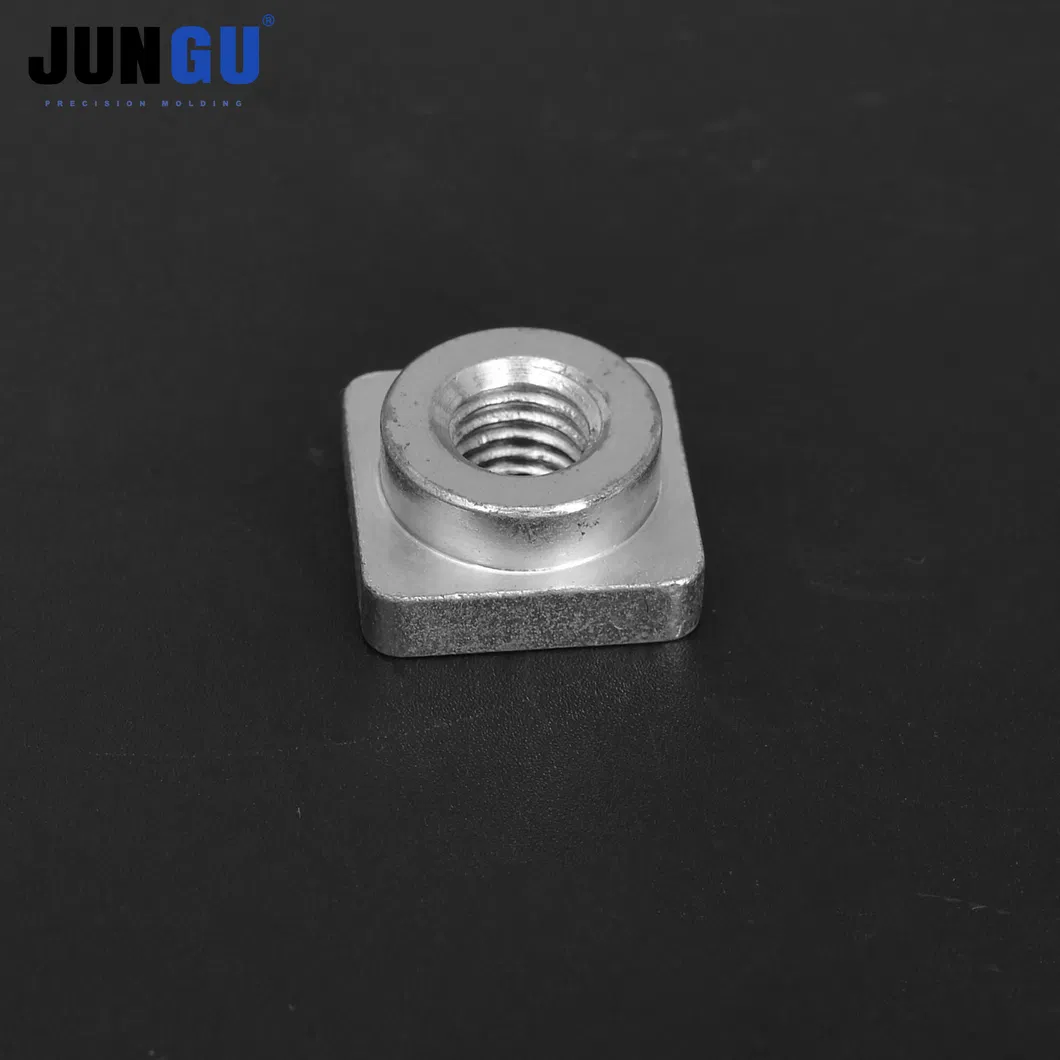

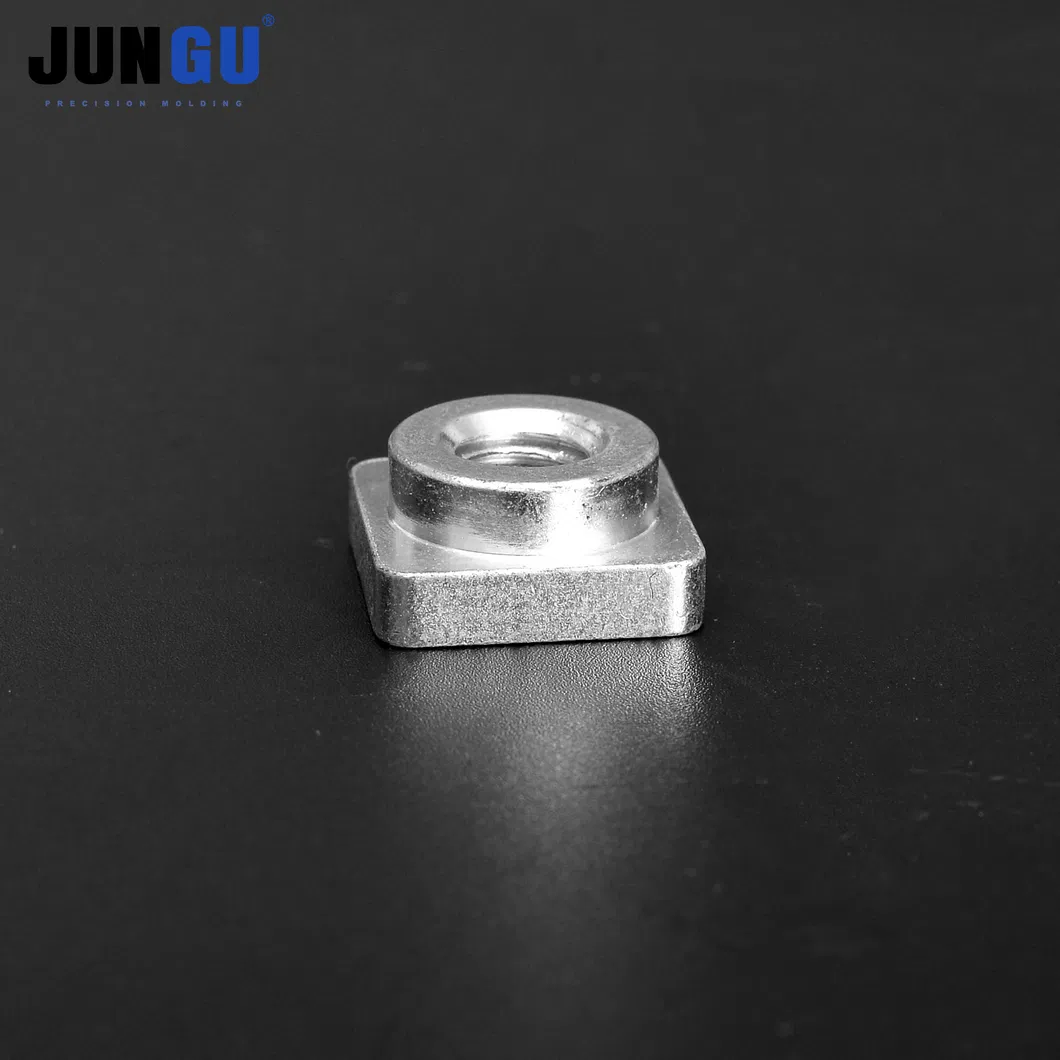

Model NO. Jg-CTO-234-5

Craftwork Polishing

Forging Work Steps Preliminary Working > Press Fit > Finish Machining

One-time Molding Not One-time Molding

Certification ISO

Warranty Product Life Based on Production Environment Habit

Metal Color Nature Metal

Customized Customized

Condition New

After-sales Service Yes

Weight Based on Customed

Precision Based on Customed

Transportation by Air/Sea/Railway

Delivery According to The Order Quantity

Sample Support Yes

Transport Package Carton

Specification Custom box gauge

Trademark JUNGU

Origin Jiangsu, China

HS Code 8207300090

Production Capacity 10000PCS

Packaging & Delivery

Package Size 20.00cm * 25.00cm * 30.00cm

Package Gross Weight 10.000kg

Product Description

Prime carbide die bolt die manufacturer

Tungsten carbide die bolt is mainly composed of tungsten carbide insert and high speed steel die case. Brass color is due to titanium coating .Tungsten carbide has the characteristics of high strength, high abrasion resistance, high hardness, high temperature resistance, etc., which can effectively improve the service life of the mould and at the same time, it can also meet the production of different materials of nuts. Our nut dies are of good quality, high precision and quick delivery. We are looking forward to cooperating with you!

Product Name

Die bolt/punch & die set /bolt die

Material

Tungsten carbide / High-speed steel /titanium

Accuracy

High-precision(0.005)

color

Metal nature

roughness

RA0.1

Advantage

High hardness , high wear resistance, high heat-resistance

Lead time

Shortly lead time(around 15 days, 10 days are available for a small number of urgent order)

Service

Customization, Design and optimization capability for improvement of mould life

Application

High strength automotive fasteners, auto parts, engineering forging parts, rail transit rivets, aerospace rivets, tensile mold products, and all kinds of standard cold heading molds.

Certification

ISO9001:2015

Processing methods

Cold heading, warm heading, hot forging, cold extrusion, stretching.

Equipment

CNC Lathes, CNC inner hole grinding machines, CNC cylindrical grinding machines, CNC Wire cutting, etc.

Company Profile

Founded in 2014, JUNGU is a professional precision fastener mold manufacturing enterprise integrating design, production, sales and service. Our factory covers an area of 10000 square meters and have 120 employees, 6 technicians, 12 engineerers, 5 people after sale service team and 178 equipments. The company mainly produces cold heading molds, including multi-station bolt and nut molds, cold extrusion molds, and vertical forging molds. Suzhou Jungu precision mould Co.,Ltd is a professional fastener mold manufacturer with 10 years of experience in molding industry. We have advanced production lines and a team of experienced stuff. We provide a full range of solutions for all kinds of cold heading mould, including multi-station bolt and nut mould, cold extrusion mould, vertical forging mould. Throughout the entire production process, we take strict quality control measures including raw materials inspection, production process monitoring and final product testing. We have built cooperation with many brands around the would. Such as EJOT, NEDSCHROEF, UNISTEEL, NM GROUP and etc. For many years, it has been in a leading position in the industry and was the first to pass the IS09001 quality management system certification. Backed by strong technical strength and talent advantages, Jungu strives to provide customers with cost-effective products and services. How to Satisfy Customers is our eternal pursuit.

Customers

We have built cooperation with many overseas clients in the word.

Packaging & Shipping

FAQ

- Q: Are you a manufacturer or a trade company? A: We are a professional manufacturer of fastener mould with 10 years of experience in this industry.

- Q: What is a cold forging die, and how does it function in the manufacturing process? A: A cold forging die is a specialized tool used to shape metal at room temperature through high-pressure deformation. It functions by applying force to a metal blank, causing it to flow into the desired shape without heating the metal.

- Q: What materials are typically used to manufacture cold forging dies, and why? A: Cold forging dies are typically made from high-grade tool steels like H13 or SKD61, or carbide. These materials are chosen for their exceptional hardness, wear resistance, and toughness, which allow them to withstand the intense pressures involved in cold forging.

- Q: What are the main advantages of using cold forging dies in production? A: The main advantages include high-strength components, cost-effective mass production, superior surface finish, and reduced energy consumption compared to hot forging, making it environmentally friendly.

- Q: What advantage do you have? A: We mainly have three capabilities:

- Professional mould simulation development and design capability.

- High-precision and high stability mould manufacturing capability.

- Optimization capability for continuous improvement of mould life.

- Q: Is it acceptable to visit your factory? A: Welcome to our factory for a visit. Our factory is located in Taicang, shouzhou city, jiangsu province, China. The traffic is very convenient.

Thank you very much!

${currentPro.title}