EN

Language

All categories

Product ID: 68568855

Corrosion-Resistant High-Fatigue LTM D-Type Mooring Shackle for Marine Hardware Connection

Contact Now

Description

Basic Info.

Model NO.

LTM shackle

Usage

Industrial, Lifting and Rigging

Color

Colored

Condition

New

Safety Factor

6:1

Standard

Ltm

Surface Treatment

Galvanized

Test Report

3rd Party Inspection Report

Proof Load Test

Yes

Transport Package

Carton

Specification

16-76mm

Trademark

Haosail

Origin

China

HS Code

7326901000

Production Capacity

500000/Year

Packaging & Delivery

Package Size

50.00cm * 40.00cm * 30.00cm

Package Gross Weight

10.000kg

Product Description

- Superior Strength: Constructed from high-tensile alloy steel, offering working load limits (WLL) ranging from 50mm to 114mm chain sizes, with proof loads up to 2,160 kN (216 tons) for larger models .

- Corrosion Resistance: Hot-dip galvanized or marine-grade coatings protect against rust and corrosion in saltwater conditions.

- Certified Compliance: Approved by ABS (American Bureau of Shipping) and compliant with DNVGL-OS-E301 standards for offshore mooring systems .

- Versatile Design: Available in D-type, Round Pin, and H-type configurations to accommodate chain-to-chain, chain-to-buoy, or chain-to-anchor connections .

- Fatigue Resistance: Engineered with advanced geometry to minimize stress concentration, ensuring long service life in cyclical loading scenarios .

- Offshore platforms, FPSOs, and MODUs

- Deepwater mooring systems

- Aquaculture net pen anchoring

- Ship-to-ship transfer operations

- Heavy-duty towing and lifting

- Rigorous Testing: Each shackle undergoes proof load testing at 2x WLL to ensure structural integrity .

- Custom Solutions: Available with customized finishes, certifications, and load ratings to meet specific project requirements.

- Global Reliability: Trusted by leading marine contractors and energy companies worldwide for their durability and safety.

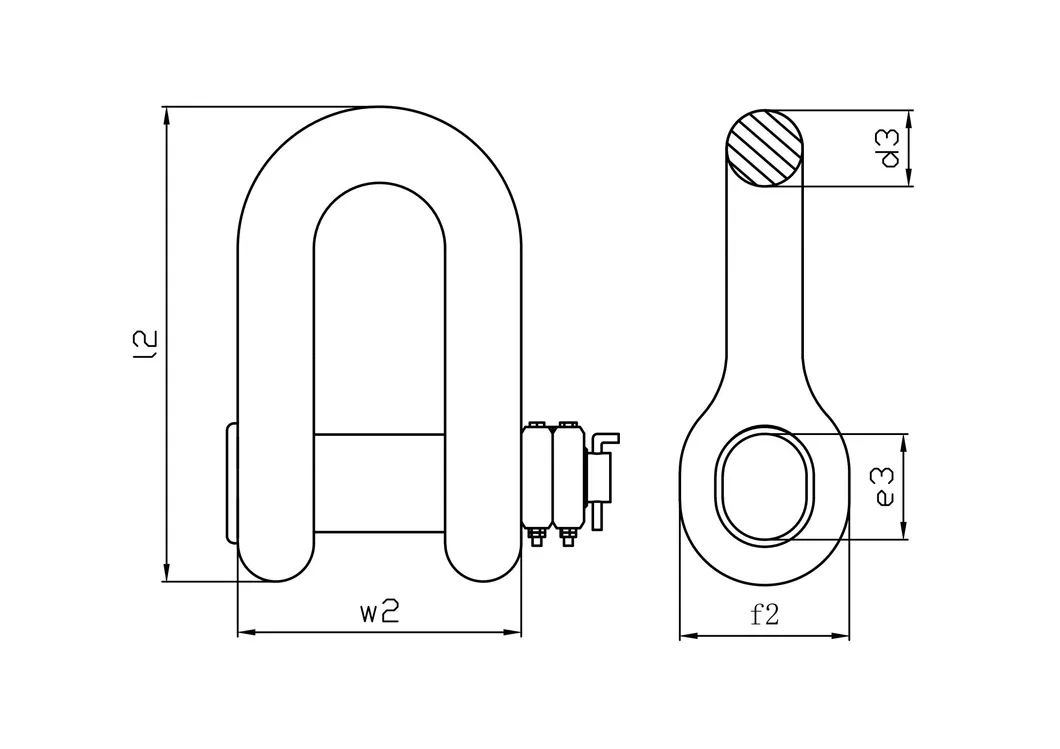

| Stock No. | Normal Size d(MM) | d3(MM) | l2(MM) | W2(MM) | e3(MM) | f2(MM) | Weight(KG) |

| HSM030605001 | 16 | 22 | 139 | 83 | 29 | 50 | 1.6 |

| HSM030605002 | 17.5 | 25 | 152 | 91 | 32 | 54 | 2 |

| HSM030605003 | 19 | 27 | 165 | 99 | 34 | 59 | 2.6 |

| HSM030605004 | 20.5 | 29 | 178 | 107 | 37 | 64 | 3.2 |

| HSM030605005 | 22 | 31 | 191 | 114 | 40 | 68 | 4.1 |

| HSM030605006 | 24 | 34 | 209 | 125 | 43 | 74 | 5.2 |

| HSM030605007 | 26 | 36 | 226 | 135 | 46 | 81 | 6.7 |

| HSM030605008 | 28 | 39 | 244 | 146 | 50 | 87 | 8.2 |

| HSM030605009 | 30 | 42 | 261 | 156 | 54 | 93 | 10 |

| HSM030605010 | 32 | 45 | 278 | 166 | 58 | 99 | 12 |

| HSM030605011 | 34 | 48 | 296 | 177 | 61 | 105 | 14.5 |

| HSM030605012 | 36 | 50 | 313 | 187 | 65 | 112 | 17 |

| HSM030605013 | 38 | 53 | 331 | 198 | 69 | 118 | 20 |

| HSM030605014 | 40 | 56 | 348 | 208 | 72 | 124 | 23 |

| HSM030605015 | 42 | 59 | 365 | 218 | 76 | 130 | 26.6 |

| HSM030605016 | 44 | 62 | 385 | 229 | 79 | 136 | 30 |

| HSM030605017 | 46 | 64 | 400 | 239 | 83 | 143 | 35 |

| HSM030605018 | 48 | 67 | 418 | 250 | 86 | 149 | 38.8 |

| HSM030605019 | 50 | 70 | 435 | 260 | 90 | 155 | 47.5 |

| HSM030605020 | 52 | 73 | 452 | 270 | 93 | 161 | 53.4 |

| HSM030605021 | 54 | 76 | 470 | 281 | 97 | 167 | 56.5 |

| HSM030605022 | 56 | 78 | 487 | 291 | 101 | 174 | 66.2 |

| HSM030605023 | 58 | 81 | 505 | 302 | 104 | 180 | 73.5 |

| HSM030605024 | 60 | 84 | 522 | 312 | 108 | 186 | 81.4 |

| HSM030605025 | 62 | 87 | 539 | 322 | 112 | 192 | 90.6 |

| HSM030605026 | 64 | 90 | 557 | 333 | 115 | 198 | 101 |

| HSM030605027 | 66 | 92 | 574 | 343 | 119 | 205 | 105 |

| HSM030605028 | 68 | 95 | 592 | 354 | 122 | 211 | 108 |

| HSM030605029 | 70 | 98 | 609 | 364 | 126 | 217 | 132 |

| HSM030605030 | 73 | 102 | 635 | 380 | 131 | 226 | 145 |

| HSM030605031 | 76 | 106 | 661 | 395 | 137 | 236 | 153 |

Contact Now

Please Send Message

${currentPro.title}