Custom Non-Standard Countersunk Flat Head Stainless Steel Machine Screw for Wood

Description

Overview

Basic Info.

Model NO.: according to customer requirement

Groove: Cross

Connection: Common Bolt

Head Style: Counter Sunk Bolt

Grade: A2-70

Inspection: 100% QC Steps Inspect Before Shipment

Delivery Time: Busy Season: 15-30 days. Slack season: 10-15 days

Transport Package: Cartons + Pallets

Specification: according to customer requirement

Trademark: Hongyuan

Origin: Zhejiang, China

HS Code: 7318159090

Production Capacity: 600 ton/Month

Packaging & Delivery

Package Size: 21.00cm * 21.00cm * 14.00cm

Package Gross Weight: 25.000kg

Product Description

Company Profile

Products name

SCREWS

Standard

DIN, ASTM/ANSI, JIS, EN, ISO, AS, GB

Material

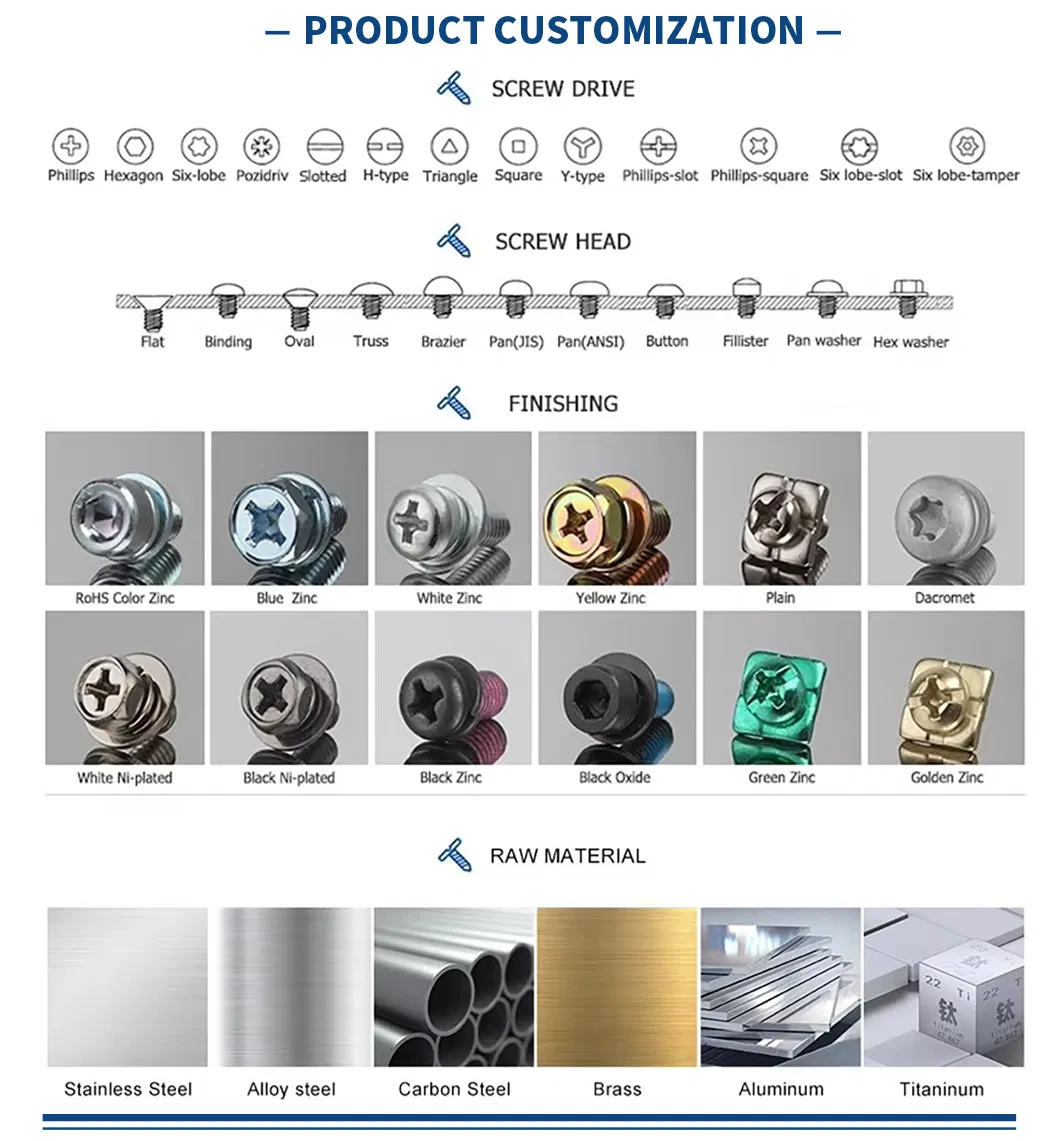

Stainless Steel: SS201, SS304, SS316; Carbon Steel: Gr A2; Aluminum

Finishing

Plain, Sand Blasting

Production Process

Cold Froging, Machining and CNC, Stamping, Welding

Customized Products

Lead time: Busy season: 15-30days, Slack seaon: 10-20days

Stock Products

Stainless steel: DIN933, DIN603, DIN912, DIN6923, DIN934, DIN125, DIN127, DIN7504K

Fress Samples for standard fastener

Factory Introduction

Ningbo Hongyuan Precision Hardware Manufacturing Co., Ltd. has been deeply involved in the industry for 20 years, always driven by technological innovation and guided by customer needs, committed to providing one-stop solutions for high-precision and high reliability fasteners.

Process and specifications

Surface Treatment:

Specification: Nickel Plated, Dumb Nickel, Black Nickel, White Zinc, Blue Zinc, Black Zinc, Yellow Zinc, Chrome Plated, Bronze Plated, Tin Plated, Silver Plated, Purified, Oxidized

Thread size: M3-M42 or customized

Length: 3-15mm or customized

Head size: 6-20mm Or customized

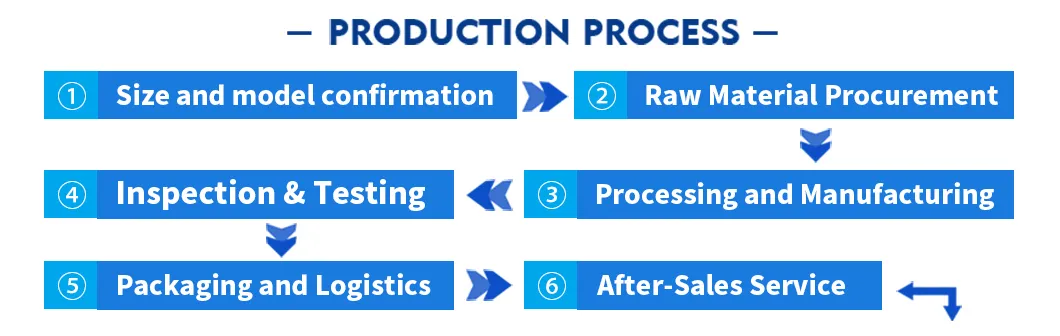

Production process

Step 1: Size and model confirmation

Hongyuan produces various high-quality fasteners and non-standard fasteners according to international standards (ISO), German standards (DIN), Italian standards (UNI), American standards (ANSI), Japanese standards (JIS), national standards (GB), etc.

Step 2: Raw Material Procurement

The annual procurement of tens of thousands of tons of raw materials allows us to take the initiative in negotiations with suppliers and strive for highly competitive prices. This significant cost advantage directly translates into competitive product prices, making us stand out in the market and winning the favor of many customers.

Step 3: Processing and Manufacturing

We are a professional fastener manufacturing enterprise with 400 high-precision machines and equipment, an annual production capacity of 3 billion screws, an annual sales revenue of 300 million yuan, and rapid growth.

Step 4: Testing and Debugging

Our company has a complete iso9001, iso14001, IATF16949 quality management system, and each product has more than 10 inspection procedures.

Step 5: Packaging and Logistics

We arrange for product transportation and logistics to ensure on-time delivery to customers.

Step 6: After-Sales Service

Once customers provide feedback on product quality issues, we will immediately initiate a quality traceability program to identify the cause of the problem. If it is indeed a product quality issue, we will provide customers with unconditional return and exchange services.

COLLABORATIVE BRAND CLIENTS

COLLABORATIVE BRAND CLIENTS

We have multiple skilled technicians with over 20 years of manufacturing experience, and each processing step is strictly inspected by dedicated quality inspectors.

CERTIFICATE

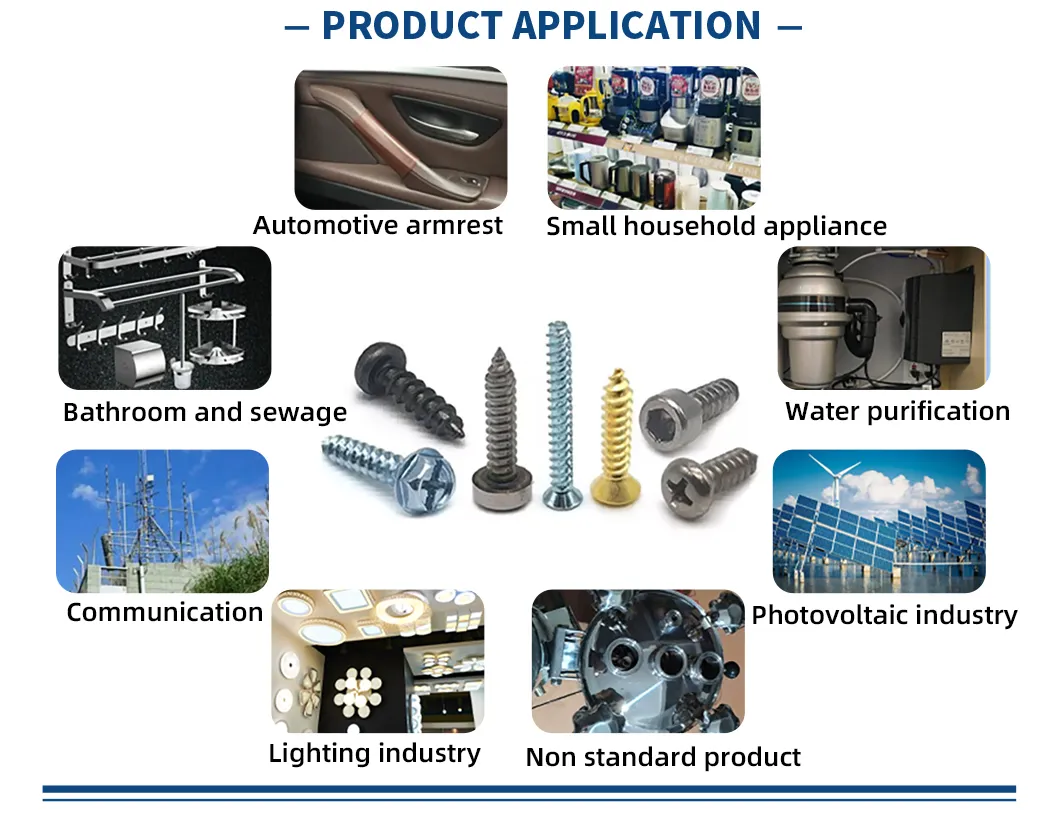

Obtained IS09001 international quality system certification, ROHS environmental testing, and SGS certification. Our products are widely used in various industries such as automotive parts, bathroom, communication, lighting, photovoltaics, small appliances, water purification, etc.

FAQ

Q1: What is your main products and material supply?

1.1. Our main products are Screws, Bolt, Nuts, rivet, Special Non-standard studs, Turning parts and High-end precision complex CNC Machining parts etc.

1.2. Carbon Steel, Alloy Steel, Aluminum alloy, Stainless Steel, Brass, Copper, Titanium alloy or according to your requirement.

Q2. When can I get the price?

We usually offer you a quotation within 12 hours, and the special offer is not more than 24 hours. Any urgent cases, please contact us directly by phone or send email to us.

Q3: If you can not find on our website the product you need how to do?

You can send the pictures/photos and drawings of the products you need by email, we will check if we have them. We develop new models every month, Or you can send us samples by DHL/TNT, then we can develop the new model especially for you.

Q4: Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Yes, we can, we can provide high precision parts and make the parts as your drawing.

Q5: How should I order and make payment?

By T/T, for samples 100% with the order;for production, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Q6: What's your Delivery Time?

Standard parts: 7-15days Non-standard parts: 15-25days We will make the delivery as soon as possible with the guarantee quality.

Q7: How to Custom-made (OEM/ODM)?

If you have a new product drawing or a sample, please send to us, and we can custom-made the hardware as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

Q8: Which mode of transport would be better?

In general, the production are heavy, we advice to make delivery by sea, Also we respect your views of other transportation as well.

${currentPro.title}