EN

Language

All categories

Product ID: 68592761

Durable Silex Lining Stone for Ball Mill Protection

Contact Now

Description

Basic Info.

Model NO.

GT-SL

Material

Natural Silica Mine

Type

Wear Resistant Plate

Sio2

99.31%

Fe2o3

0.018%

Al2O3

0.36%

Hardness

>=8 Mohs

Volume Density

>=2.66g/cm3

Actual Abrasion Rate of Pebble

<=1.35

Porosity

<=0.38%

Color

Gray and White

MGO

0.04%

Cao

0.09%

Transport Package

Bags or Wooden Cases

Specification

Height: 110-200 mm

Trademark

GAOTENG

Origin

China Mainland

HS Code

6802939000

Production Capacity

10000tons/Year

Product Description

Production Information

Technical Data

Technical Data

Why choose us

Product Feature

1. Long lining life---2.5 to 3 years

2. High silica content - 99.31% min

3. Wear resistance---density 2.66~2.68g/cm3,hardness 7-8mohs

4. Easy installation

5. Provide installation service on site

Company Strength

1. Workers with 30 years of cutting experience

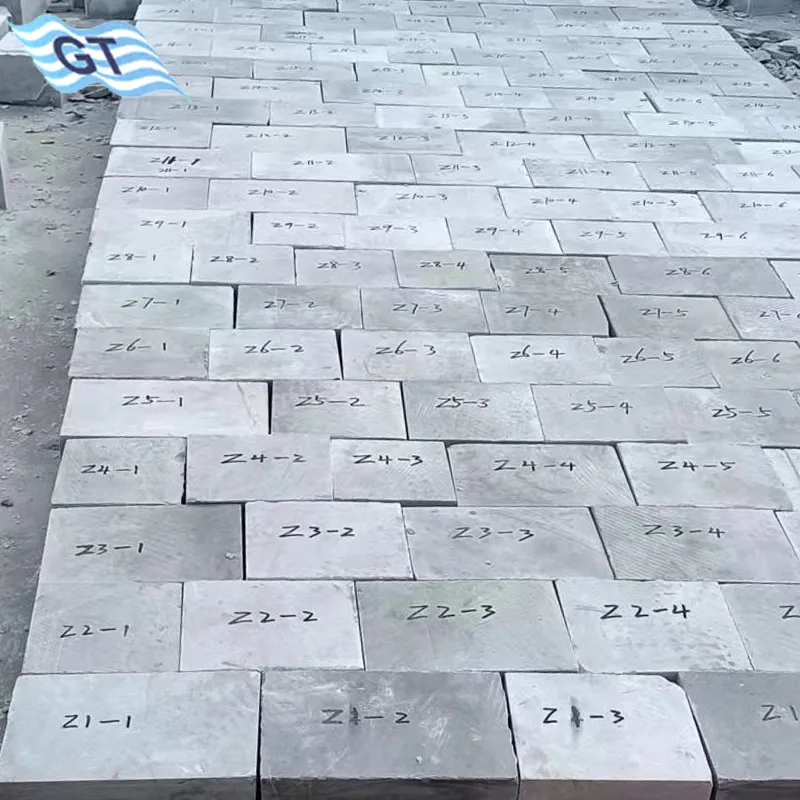

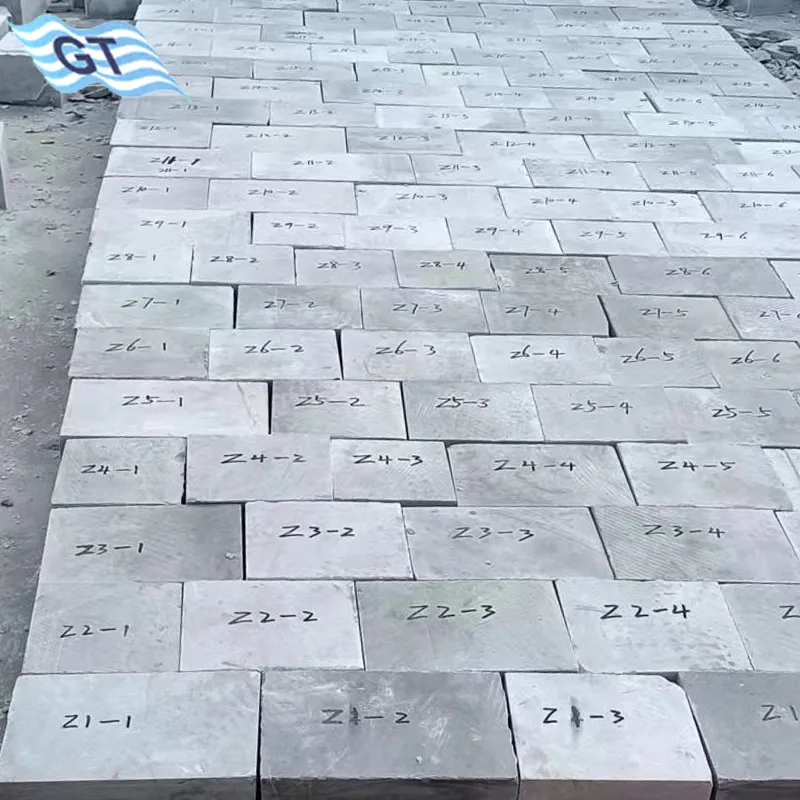

2. Marks numbers on every stone, more convenient to install

3. Provide HD stone photos and drawings

4. Provide installation service and guide video

5. Cutting inlet and outlet with free charge

Our Company

Certificate

Our Customers

We have had more than 180 customers from over 40 countries and regions since Gaoteng was founded, and many of them have cooperated with us for more than 10 years.

Our Team

Packing Details

Application fields

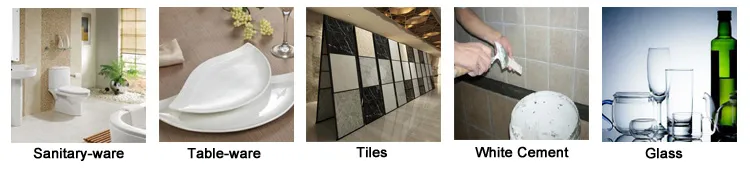

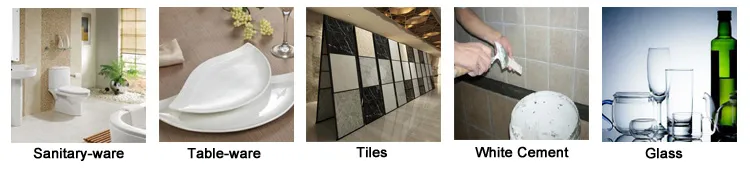

It is used as an inner lining for ball milling, with high SiO2 content, and perfect hardness, for the production of industrial raw materials, glass, porcelain, ceramic processing, alumina fine powder grinding, and all kinds of mineral production, suitable for pot milling, continuous ball mill, batch ball mill.

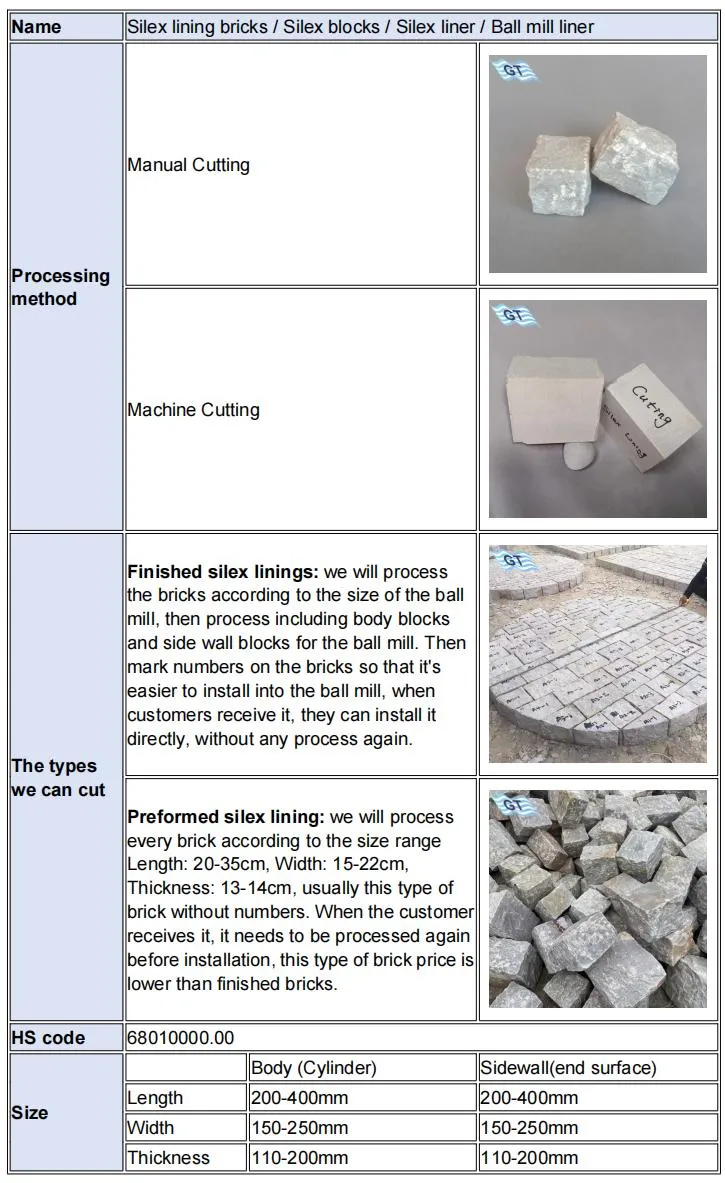

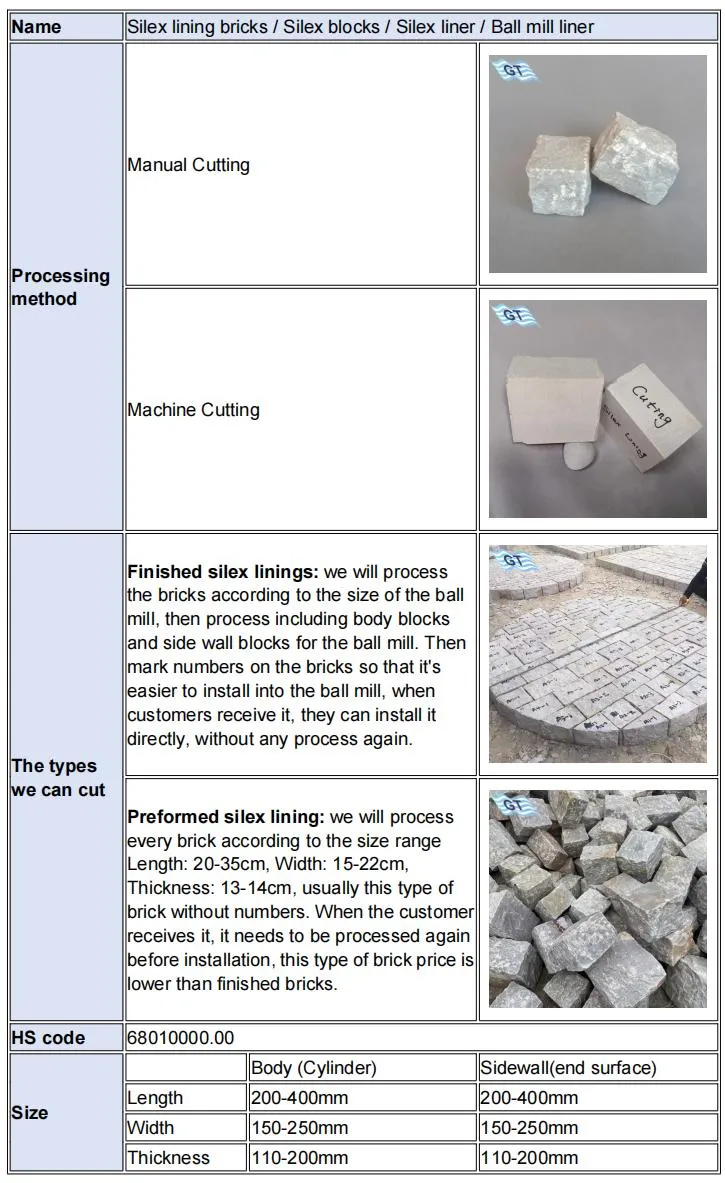

We can produce different sizes according to customer specifications and the size of the ball mill, mainly supply two types, manual cutting and Machine cutting.

FAQ

Q: Are you a trading company or a manufacturer?

For silica pebbles and silex lining bricks, we are a manufacturer with more than 30 years of experience.

Q: Which countries do you mainly export to?

Most of our customers are in Japan, Southeast Asia, the Middle East, Europe, etc ...

Q: What is the annual output of Silex lining bricks?

1000 tons per year.

Q: What information do we need to prepare if we want to get an exact quotation from you?

For silex blocks, you need to kindly tell us your ball mill size (Diameter and Length) and the thickness of bricks you prefer. Then we will calculate the weight you need for one ball mill and give you a reasonable price.

Q: The Size of silex lining bricks:

Usually, the thickness of the sidewall is thinner than the body.

Length and width usually are a range, different sizes assure the blocks to be stably installed on the ball mill.

The sum of the width for all rows is equal to the perimeter of the ball mill, and the sum of the length for all columns is equal to the length of the ball mill.

Q: What's the processing method of silex lining?

We can supply both manual and machine cutting, most of the customers are used to choosing manual.

Q: How many years can ball mill lining use?

For silex lining and alumina lining, normally 2.5-3 years, it will be decided by what material is used to grind, usually grind ceramic glaze material, the use time will be longer.

Q: What material is used to paste lining into a ball mill?

Usually, our customers use high alumina cement, A600.

Q: Is it possible to send samples for testing before ordering?

Certainly, we can send a free sample to test.

Q: What payment terms does your company usually do?

We can accept 100% T/T in advance or L/C at sight for the first cooperation.

Q: How to deliver the goods?

For the sample, we will use express such as DHL, TNT, UPS, and FEDX to send the goods.

For the mass production batch, we will use sea transportation for you.

Related Products

Technical Data

Technical Data

| SiO2 | ≥99.31% | Volume Density | ≥2.66~2.68g/cm3 | |

| Fe2O3 | ≤0.018% | Porosity | ≤0.38% | |

| Al2O3 | ≤0.36% | Actual abrasion rate | ≤1.35 | |

| CaO | 0.09% | Hardness | around 8 | |

| MgO | 0.04% | Color after burning | White |

Why choose us

Product Feature

1. Long lining life---2.5 to 3 years

2. High silica content - 99.31% min

3. Wear resistance---density 2.66~2.68g/cm3,hardness 7-8mohs

4. Easy installation

5. Provide installation service on site

Company Strength

1. Workers with 30 years of cutting experience

2. Marks numbers on every stone, more convenient to install

3. Provide HD stone photos and drawings

4. Provide installation service and guide video

5. Cutting inlet and outlet with free charge

Our Company

Certificate

Our Customers

We have had more than 180 customers from over 40 countries and regions since Gaoteng was founded, and many of them have cooperated with us for more than 10 years.

Our Team

Packing Details

Package Details |

Size | Bag:100cm x 100cm x 100cm Pallet:100cm x 100cm Wooden cases |

| Weight: | 1000-1300kg per bag 25-27 tons per 20'FCL 20 packages per 20'FCL |

|

| Mark and Label: | Customizable |

Application fields

It is used as an inner lining for ball milling, with high SiO2 content, and perfect hardness, for the production of industrial raw materials, glass, porcelain, ceramic processing, alumina fine powder grinding, and all kinds of mineral production, suitable for pot milling, continuous ball mill, batch ball mill.

We can produce different sizes according to customer specifications and the size of the ball mill, mainly supply two types, manual cutting and Machine cutting.

FAQ

Q: Are you a trading company or a manufacturer?

For silica pebbles and silex lining bricks, we are a manufacturer with more than 30 years of experience.

Q: Which countries do you mainly export to?

Most of our customers are in Japan, Southeast Asia, the Middle East, Europe, etc ...

Q: What is the annual output of Silex lining bricks?

1000 tons per year.

Q: What information do we need to prepare if we want to get an exact quotation from you?

For silex blocks, you need to kindly tell us your ball mill size (Diameter and Length) and the thickness of bricks you prefer. Then we will calculate the weight you need for one ball mill and give you a reasonable price.

Q: The Size of silex lining bricks:

Usually, the thickness of the sidewall is thinner than the body.

Length and width usually are a range, different sizes assure the blocks to be stably installed on the ball mill.

The sum of the width for all rows is equal to the perimeter of the ball mill, and the sum of the length for all columns is equal to the length of the ball mill.

Q: What's the processing method of silex lining?

We can supply both manual and machine cutting, most of the customers are used to choosing manual.

Q: How many years can ball mill lining use?

For silex lining and alumina lining, normally 2.5-3 years, it will be decided by what material is used to grind, usually grind ceramic glaze material, the use time will be longer.

Q: What material is used to paste lining into a ball mill?

Usually, our customers use high alumina cement, A600.

Q: Is it possible to send samples for testing before ordering?

Certainly, we can send a free sample to test.

Q: What payment terms does your company usually do?

We can accept 100% T/T in advance or L/C at sight for the first cooperation.

Q: How to deliver the goods?

For the sample, we will use express such as DHL, TNT, UPS, and FEDX to send the goods.

For the mass production batch, we will use sea transportation for you.

Related Products

Contact Now

Please Send Message

${currentPro.title}