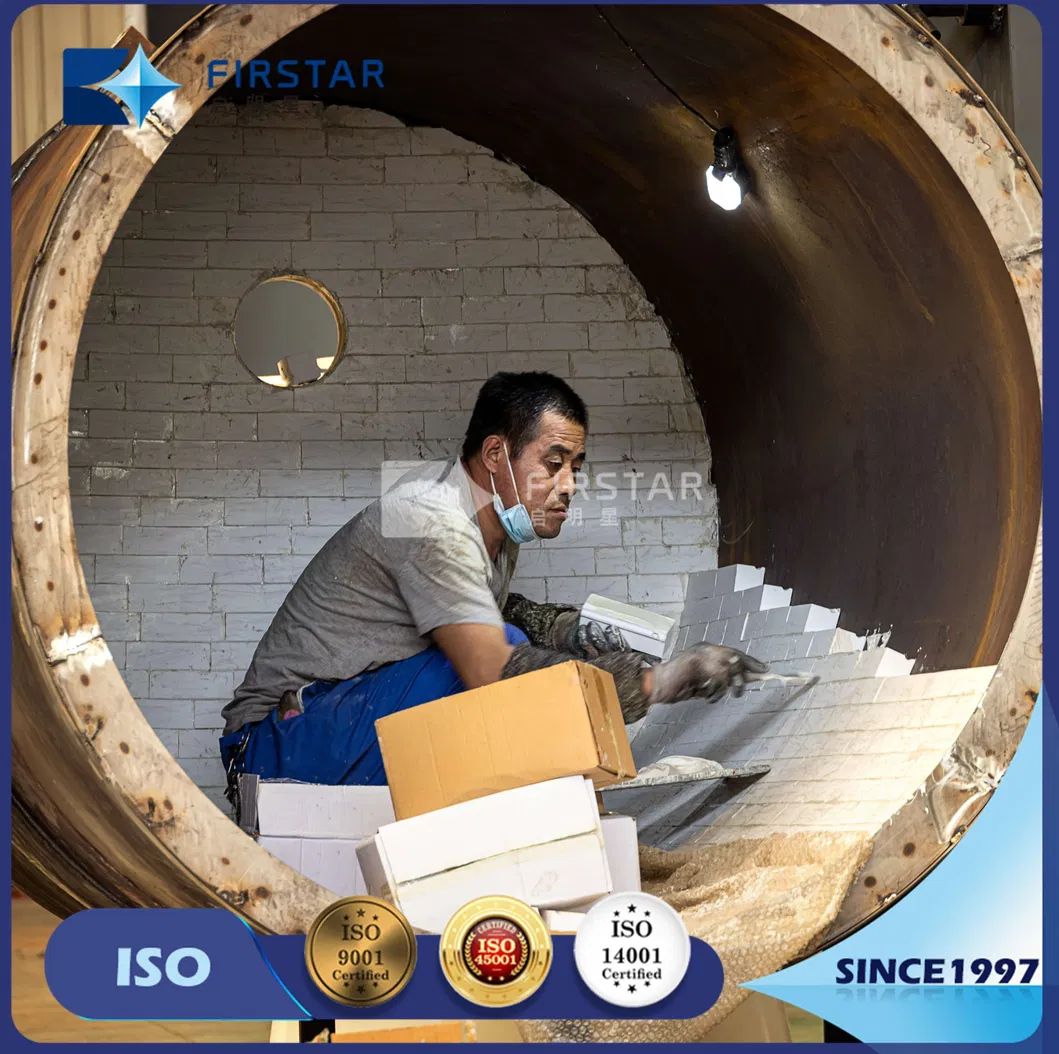

Ceramic Ball Mill Brick Lining for Sale

Description

Overview

Basic Info.

- Model NO. Ball Mill Bricks

- Material Aluminum

- Type Wear Resistant Ceramic

- Square Tile 10X10X3~10mm, 17.5X17.5X3~15mm, 20X20X3~15mm, etc.

- Ceramic Plate 100X100X6~50mm, 150X100X6~50mm, etc.

- Hexagonal Tile S12.5xt3~20mm, S23.5xt6-25mm

- Dimple Tiles 20X20X4-10+1(with 5 Dimples), 20X30X5~15+1(with 18)

- Ceramic Block 40X40X40mm, 45X45X50mm, 32X32X22mm, 38X38X38mm, etc.

- Ceramic Cylinder/Rod 6X6mm, 15X15mm, 20X20mm, 31X31mm, 40X40mm, 45X50mm, 5

- Al2O3 92%

- Density 3.6g/cm³

- Hv 20 950

- Rock Hardness Hra 82

- Bending Strength MPa 220

- Compression Strength MPa 1050

- Fracture Toughness Kic Mpam 1/2 3.7

- Wear Volume 0.25 Cm³

- Color White

- Transport Package CTN

- Specification customized size

- Trademark firstar

- Origin China

- HS Code 6909120000

- Production Capacity 400t/Month

Product Description

92% 95% Abrasive Resistant Ceramic Alumina Plate Tiles for Composite Ceramic Rubber Panel is a high-performance abrasion and impact resisting linings for high-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. In extreme applications, the Cube liners can be installed in a matrix or abrasion resistant steel plate to provide structural support for the ceramic/rubber matrix and provide exceptional wear life where competing products cannot. Used in heavy industry for years as a cost-effective, wear-resistant solution, these lightweight materials offer high durability, strength, and excellent abrasion and corrosion resistance. Alumina wear resistant compositions include:

- Alumina 92: most common wear product with great wear resistance

- Alumina 95: increased wear performance

- Alumina T95: premium alumina for best wear resistance

- Zirconium toughened alumina (ZTA): increased strength and impact resistance

Product Features:

- > High hardness

- > Superior abrasion and impact resistance

- > Corrosion and chemical resistance

- > Light weight

- > Easy installation by epoxy resin or bolt

- > Improve your working environment - noise, vibration and safety

Product Specification:

- - Square tile: 10x10x3~10mm, 17.5x17.5x3~15mm, 20x20x3~15mm, etc.

- - Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.

- - Hexagonal tile: S12.5xT3~20mm, S23.5xT6-25mm

- - Dimple tiles: 20x20x4-10+1(with 5 dimples), 20x30x5~15+1(with 18 dimples), 20x20x5-10mm( with 13 dimples)

- - Ceramic Block: 40x40x40mm, 45x45x50mm, 32x32x22mm, 38x38x38mm, etc.

- - Ceramic Cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 45x50mm, 50x50mm etc.

Ceramic wear lining tiles for a variety of applications:

- Processing equipment:

- Pharmaceutical clean rooms

- Food processing plants

- Grain handling

- Mineral processing

- Cement manufacturing

- Chemical processing

- Large Cyclones:

- Coal-fired power plants

- Steel Mills

- Asphalt Plants

- Petrochemical plants

- Pulp and paper mills

Product Parameters

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

|---|---|---|---|---|---|---|---|

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | >3.50g/ cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Detailed Photos

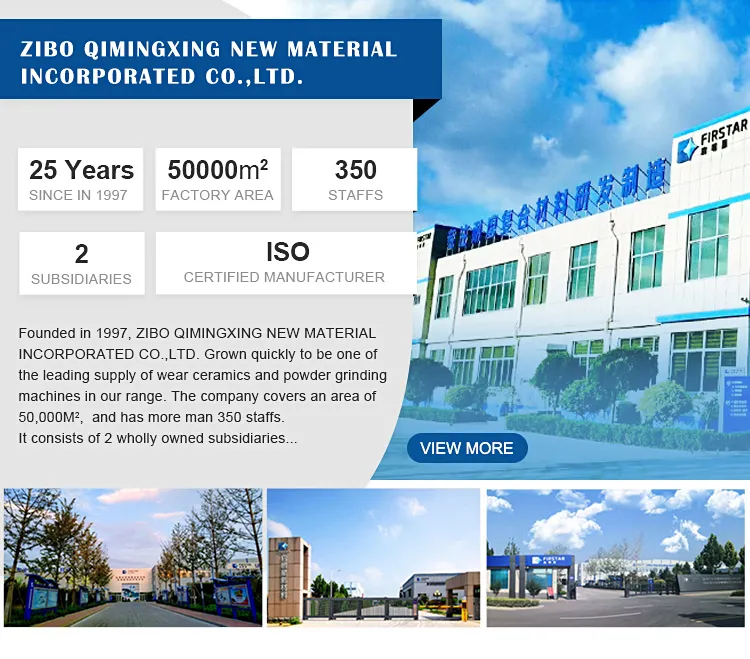

Company Profile

Qimingxing offers quality wear and anti-impact ceramics, in combination with our experienced and competent staff, ensure the increased efficiency and service life of all equipments and materials to which they are applied. - Established Ultrafine Energy Efficiency Technology Research Institute - Increase lifespan of wearable parts - New improved technology and products - Minimal downtime to minimize delays in production - Variety of wear combating options available as a one stop solution - Strong focus on product innovation supported by Chinese Academy of Sciences. - Customized application techniques to suit any wear problem

${currentPro.title}