Continuous ceramic ball mill/ball mill/ball mill sale

Description

Continuous ceramic ball mill

- 【Processing capacity】:0.4-2(t/h)

- 【Motor Power】:15(kW)

- 【Application range】:Applies to ceramics,electromagnetism,fire-proof material industries.

Equipment introduction

Ceramic ball mill is a new type of energy-saving ball milling equipment developed by mechanical experts in combination with the latest domestic ball milling technology not only improves the production capacity and crushing efficiency, but also expands the scope of application.

Performance characteristics

The fineness of grinding operation depends on the grinding time. The motor is started by self decompression to reduce the starting current. Its structure is divided into integral independent type. This product has the characteristics of less investment, energy saving and power saving compared with similar products, novel structure, simple operation, safe use, implicit and reliable performance, etc. Suitable for mixing and grinding of ordinary and special materials. Users can comprehensively consider and select the appropriate model, lining plate and medium type according to the specific gravity and hardness of the material, as well as the output and other factors.

working principle

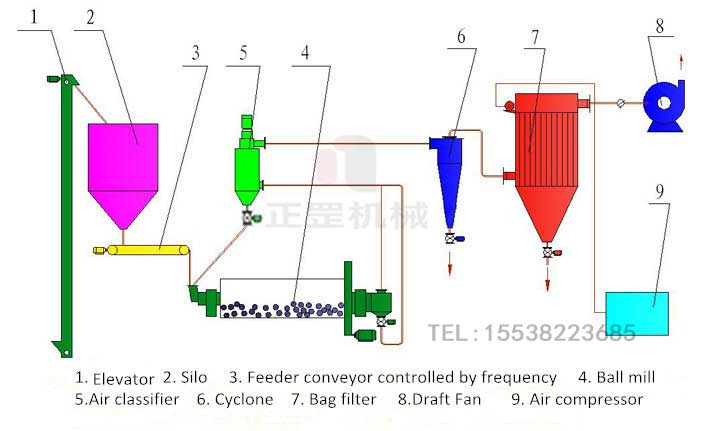

Features of Superfine Ball Mill GRINDING Production Line:

1. Low energy consumption: LHM superfine ball mill production line adopted high advanced energy-saving technology and classification technique; as a result, our production line can save over 40% energy for producing same quantity materials.

2. Several times of classification could be obtained:

Finished product fineness after first time classification: 300-2500mesh; if our ball mill production line is equipped with a second classification system, the finished product fineness after second time classification would be 6,250mesh (d97≤2um).

3. Adopted highly advanced self-diffluent classification system:

4. Scientific grinding medium enable us to produce large quantity superfine particles.

5. Different lining boards and grinding mediums are available for milling different materials, so as to guarantee the purity and whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our ball mills and classifiers in the production lines are VFC controlled and have high automation;

8. Negative pressure production condition gives a good production environment;

9. High annual production capacity: 5-500 thousand tons.

Technical Parameters

| Model |

Cylinder diameter(mm) |

Cylinder length(mm) |

Cylinder RPM(r/min) |

Motor power(kW) |

Effective volume(m3) |

Max ball load (t) |

Capacity(t/h) |

Weight(t) |

| MQY 0918 |

900 |

1800 |

38 |

15 |

0.9 |

1.66 |

0.4-2.0 |

5.28 |

| MQY 1224 |

1200 |

2400 |

32 |

30 |

2.28 |

3.8 |

0.8-3.5 |

9.3 |

| MQY 1530 |

1500 |

3000 |

28.8 |

75 |

5 |

10 |

3.8-12 |

16.9 |

| MQY 1830 |

1800 |

3000 |

24.5 |

185 |

9 |

20 |

4.5-19 |

29.2 |

| MQY 1836 |

1800 |

3600 |

24.5 |

210 |

10.8 |

22 |

5.2-22 |

31.4 |

| MQY 1845 |

1800 |

4500 |

24.5 |

245 |

13.5 |

23.8 |

6.0-25 |

33.6 |

| MQY 2130 |

2100 |

3000 |

23.8 |

185 |

9 |

20 |

5.5-24 |

39.2 |

| MQY 2136 |

2100 |

3600 |

23.8 |

210 |

10.8 |

22 |

6-28 |

41 |

| MQY 2145 |

2100 |

4500 |

23.8 |

245 |

13.5 |

23.8 |

7.2-32 |

45.8 |

| MQY 2430 |

2400 |

3000 |

21.7 |

280 |

12.1 |

23 |

9-39 |

51 |

| MQY 2436 |

2400 |

3600 |

21.7 |

280 |

14.5 |

23 |

10-42 |

52.6 |

| MQY 2445 |

2400 |

4500 |

21.7 |

320 |

18.2 |

23 |

10-45 |

56 |

| MQY 2721 |

2700 |

2100 |

21.4 |

280 |

10.7 |

24 |

10-84 |

63.9 |

| MQY 2736 |

2700 |

3600 |

21.4 |

400 |

18.4 |

32 |

12-95 |

76.8 |

| MQY 2745 |

2700 |

4500 |

21.4 |

450 |

20.5 |

40 |

13-145 |

83.5 |

| MQY 3231 |

3200 |

3100 |

18.6 |

630 |

22.65 |

45 |

20-185 |

107 |

| MQY 3245 |

3200 |

4500 |

18.6 |

630 |

32.8 |

65 |

30-200 |

121 |

| MQY 3254 |

3200 |

5400 |

18.6 |

1000 |

39.2 |

73 |

35-245 |

129 |

| MQY 3645 |

3600 |

4500 |

17.3 |

1000 |

40.8 |

76 |

30-220 |

155 |

| MQY 3650 |

3600 |

5000 |

17.3 |

1250 |

45.4 |

86 |

35--256 |

159 |

| MQY 3660 |

3600 |

6000 |

17.3 |

1250 |

54.5 |

102 |

38-270 |

174 |

|

1. Are you manufacture or trading company? We are factory. 2. How long is your delivery time? 7-10 days for the stock, 15-30 days for the mass production. 3. What is your payment method? 30% deposit in T/T advance, 70% balance before shipment. 4. How long is the warranty? Does your company supply the spare parts? One year. Spare parts for you at lowest cost. 5. If I need the complete crushing plant can you help us to build it? Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.  |

${currentPro.title}