rod mill / wet rod mill / rod mill for sale

Description

Rod mill

- 【Processing capacity】:1.3-300(t/h)

- 【Motor Power】:22-1120(kw)

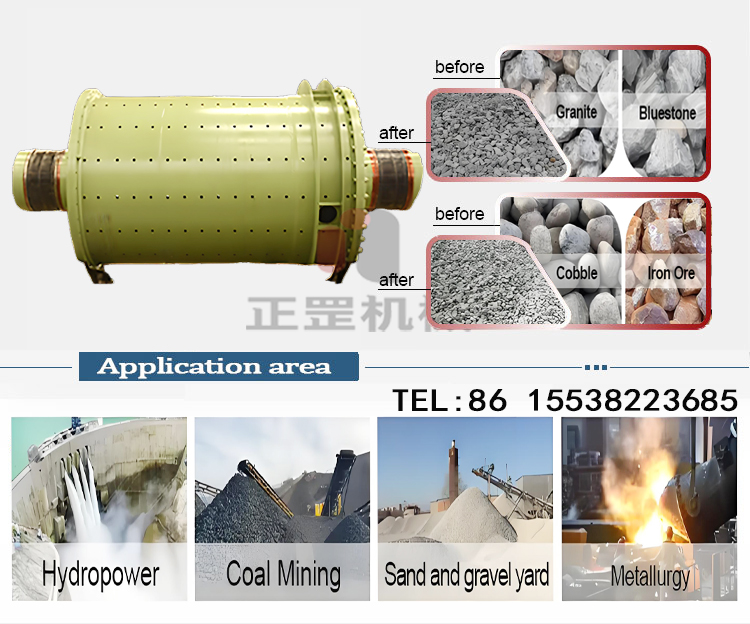

- 【Application range】:Widely used in artificial stone sand, concentrating plants, chemical plant power sector, ore, cement, silicate products, building materials, refractory materials, fertilizers, glass, ceramics and metal beneficiation.

Performance characteristics

working principle

Technical Parameters

| Model |

Cylinder diameter |

Cylinder |

Volume(m3) |

Cylinder |

Bar |

Feeding |

Discharging size |

Capacity |

Motor power |

Weight (t) |

| MB0918 |

900 |

1800 |

0.9 |

35.4 |

2. 5 |

<25 |

0. 2-2.5 |

1. 3-2.6 |

22 |

5.2 |

| MB0924 |

900 |

2400 |

1.2 |

35. 4 |

3.5 |

<25 |

0. 2-2.5 |

1.35-2.9 |

30 |

5. 6 |

| MB1224 |

1200 |

2400 |

2,28 |

34 |

4.8 |

<25 |

0. 2-2.5 |

2. 0-5. 0 |

55 |

13. 5 |

| MB1530 |

1500 |

3000 |

5 |

26. 5 |

8 |

<25 |

0. 2-2.5 |

4.8-12 |

95 |

16.7 |

| MB1836 |

1830 |

3600 |

7.6 |

22.5 |

17 |

<25 |

0. 2-2.5 |

6-17 |

132 |

31 |

| MB2130 |

2100 |

3600 |

9.2 |

20.9 |

22 |

<25 |

0. 2-2.5 |

14-40 |

155 |

37 |

| MB2136 |

2100 |

3600 |

11 |

20.9 |

24 |

<25 |

0. 2-2.5 |

15-45 |

210 |

39 |

| MB2436 |

2400 |

3600 |

14.6 |

19 |

28 |

<25 |

0. 8-5.0 |

26-65 |

280 |

58 |

| MB2736 |

2700 |

3600 |

18.4 |

17.5 |

42 |

<25 |

0. 8-5.0 |

30-125 |

400 |

86 |

| MB2740 |

2700 |

4000 |

20.5 |

17.5 |

47 |

<25 |

0. 8-5.0 |

40-150 |

400 |

91 |

| MB3040 |

3000 |

4000 |

25.9 |

16.2 |

51 |

<25 |

0. 8-5.0 |

62-165 |

500 |

130 |

| MB3245 |

3200 |

4500 |

33 |

15.5 |

56 |

<25 |

0. 8-5.0 |

70-210 |

630 |

137 |

| MB3250 |

3200 |

5000 |

35 |

15.5 |

60 |

<25 |

0. 8-5.0 |

75-240 |

710 |

143 |

| MB3645 |

3600 |

4500 |

40.8 |

14.5 |

78 |

<25 |

0. 8-5.0 |

83-260 |

1000 |

168 |

| MB3654 |

3600 |

5400 |

50 |

14.5 |

94 |

<25 |

0. 8-5.0 |

100-330 |

1120 |

192 |

Advantages

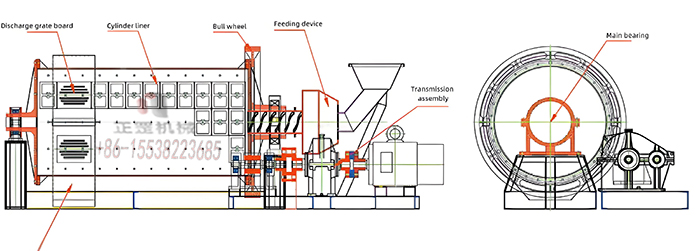

1. Iron rods can move inside mill with regularity.The curvature of end cover of wet rod mill is relatively small, which renders iron rods move inside mill with regularity.

2. Easy installation and maintenance.

3. Quick discharging.The diameter of discharge hollow shaft is comparatively bigger, which makes overhaul easier and diminishes the liquid level of ore pulp. Consequently, discharge becomes faster.

4. Uniform ore particles.

5. Low incidence of overly grinding.Uniform ore particles. Less incidence of overly grinding.

|

FAQ

|

Q1: Are you trading company or manufacturer? A: We are factory.

Q2: How long is your delivery time? A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method? A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service. What minerals are you separating? What's the maximum size of your raw minerals? Q5: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost. Q6: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you combine a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.

Q7:what's your motor brand?what bearing do you use?

For Motor-China top brand, also can use Siemens as per request .

For Bearing China top brand ZWZ, also can use SKF/NSK etc as per request

|

${currentPro.title}