EN

Language

All categories

Product ID: 66299642

Spiral Classifier/High weir spiral classifier/Spiral Classifier for sale

Contact Now

Description

Spiral classifie

The spiral classifier mainly has four types of sorghum single helix and double helix, sinking single helix and double helix. The sand returning end of the improved spiral classifier manufactured by our company has increased the automatic sand returning device, so the configuration of the large head of the ball mill can be eliminated, and the ball mill runs mo.

Equipment introduction

Performance characteristics

The classifier is widely used in the concentrating plant to form a closed loop recirculating ore with the ball mill, or to classify the ore and fine mud in the gravity concentrating plant, and to classify the slurry in the metal beneficiation process, and to wash the ore. Desliming, dehydration and other operations during the operation. The classifier has the characteristics of simple structure, reliable operation and convenient operation.

Applicable Materials

working principle

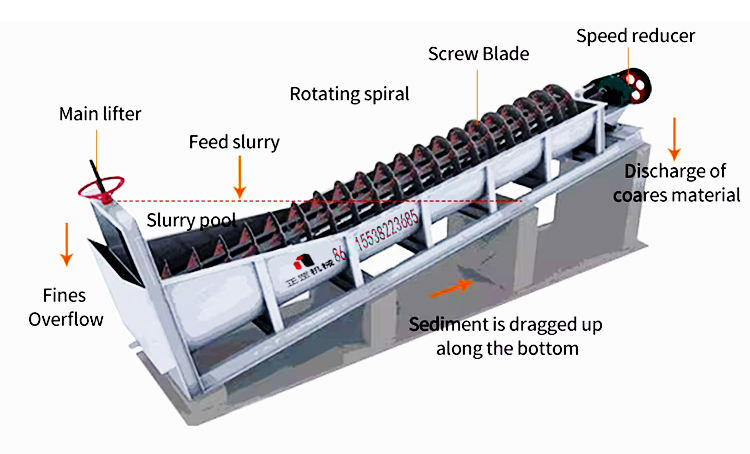

The sinking type spiral classifier is made up of different solid particles and different specific gravity, so the sedimentation speed in the liquid is also different. The fine ore particles float in the water and overflow, and the coarse ore particles sink to the bottom of the tank and are pushed out by the screw. A grading device for mechanical grading. By rotating the screw at a low speed, the slurry is agitated to suspend the fine particles to the top, and overflows to the overflow weir, and the coarse particles sink to the bottom of the tank, and are transported by the screw to the discharge port for discharge.

Technical Parameters

| Model | Screw diameter(mm) | Tank length(mm) | Screw RPM(r/min) | Capacity(t/d) | Motor power(kw ≤) | Dimension(mm≤) | Weight(t) | ||||

| Sand return | Overflow | Drive | Lifting | Length | Width | High | ≤ | ||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | ---- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11.0 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41.0 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73.0 |

| 2FC-30 | 14300 | 23300 | 1410 | ---- | ---- | 17091 | ---- | 8680 | 84.8 | ||

FAQ

|

1. Are you manufacture or trading company? We are factory. 2. How long is your delivery time? 7-10 days for the stock, 15-30 days for the mass production. 3. What is your payment method? 30% deposit in T/T advance, 70% balance before shipment. 4. How long is the warranty? Does your company supply the spare parts? One year. Spare parts for you at lowest cost. 5. If I need the complete crushing plant can you help us to build it? Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.  |

Contact Now

Please Send Message

${currentPro.title}