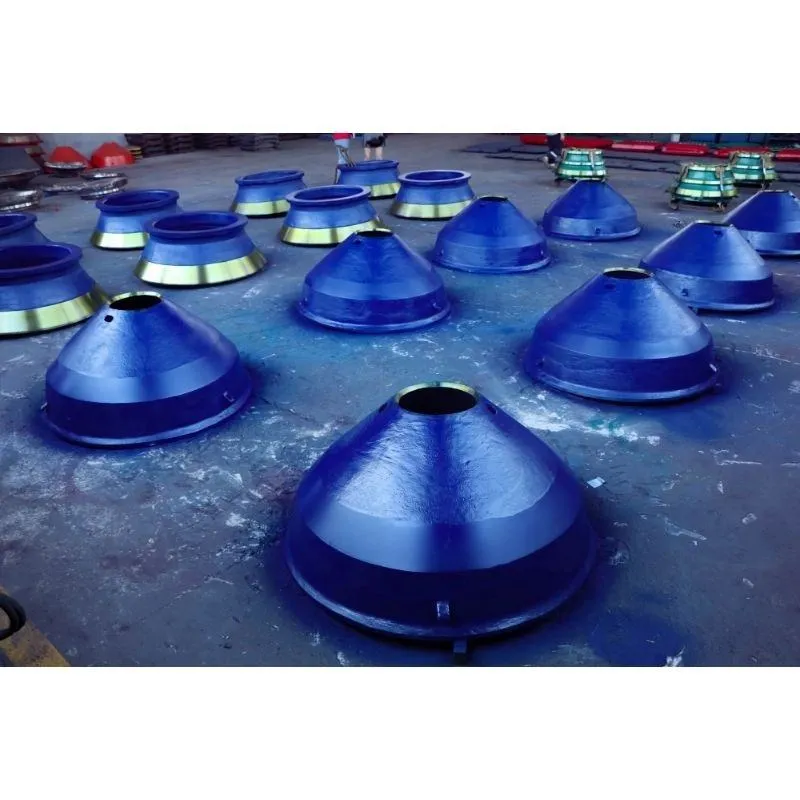

Manganese Steel Mantle for Cone Crusher

Description

Basic Info.

Product Description

Description

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

HONGFEI cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

Case studies and customer reports comparing our wear liners to other suppliers have displayed up to a 50% increase in wear life across various applications using the identical profile design,

Our technical sales team, product engineers and pattern makers work closely together alongside our customers to develop and modify heavy duty jaw, cone and gyratory liner designs to further increase wear life, some of these modified designs have increased wear life in excess of 300% over standard design liners.

| Product Name | mantle and bowl liner for cone crusher |

| Type | mantle , bowl liner |

| Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2 |

| Foundry technology | sand casting |

| Lead time | 20-50days, according to products details and order quantities |

| Shipment | according to clients request |

| Technical support | drawing , surveying and mapping |

| Quality testing | dimentional checkout , hardness inspection, metallographic test , ingredients analysis, PT(penetration testing), destructive test(impact, bending test... |

| Certification | SGS , ISO9001 , ISO45001 , ISO14001 |

| Service | 24 hours online service |

Why Choose HONGFEI Mantle & Bowl Liner

1. We offer OEM interchangeable cone crusher parts & liners;

2. We offer a variety optional materials of cone crusher mantles and bowl liners;

3. We produce more wear-resistant products;

4. We extend the service life of the mantle and bowl liner;

5. We provide more competitive prices;

6. We provide more professional services and suggestions.

High Manganese Steel Cone Crusher Mantle & Bowl Liner

For the material of concave, HONGFEI use the Hadifield-steel , like Mn13Cr2,Mn18Cr2,Mn22Cr2, to ensure the wear resistance. Our cone parts are widely used on mining, constrution, chemical, cement and metallurgical indusery. After the modification treatment, combining with the special processing techniques, concave have a service life 10%-15% longer than those made of traditional materials.

Chemical Composition & Machanical Property Of High Manganese Materials

| Materials | Chemical Composition (%) | Machanical Property | ||||

| Mn | Cr | C | Si | Ak/cm | HB | |

| Mn13Cr2 | 12-15 | 1.7-2.2 | 1.15-1.25 | 0.3-0.8 | >140 | ≤220 |

| Mn18Cr2 | 17-19 | 1.8-2.2 | 1.15-1.3 | 0.3-0.8 | >140 | ≤220 |

| Mn22Cr2 | 21-23 | 1.8-2.2 | 1.1-1.4 | 0.3-0.8 | >140 | ≤220 |

Hongfei Machinery Manufacturing Co.,Ltd is located in Lanxi City,Zhejiang Province as a leading manufacturer of wear- resistant castings in China . We specializes in the production of high manganese steel, high chromium cast iron, alloy steel and other crusher accessories, annual output more than 15,000 tons. Our products are served for jaw crusher, cone crusher, impact crusher, ball mill, Raymond mill, sanding machine and other types of machines in mining, sand, cement, chemical industries more than 20 years.The main products are: jaw plate, mantle,bowl line, hammer, blow bar, liner,roller, mill ring etc.Company has a comprehensive production base of more than 50,000 square meters, with over 200 employees and more than 30 technical, R&D and QC team.

FAQ

FAQ

Q1. What's your company's casting methods?

A: We support sand casting and lost foam casting.

Q2. Can you make products without drawing?

A: No, we can only make products strictly according to customers'

technical drawing. Because every spare parts must be install to

the equipment even little error will make big problem.

Q3. How about the lifetime of your wear spare parts?

A: Different working condition make different results based on same

products. You buy our products and try them, you will know our

quality.

Q4. What's the delivery time?

A: About 20-50days , according to the products detail request .

Q5. What's the payment term does your company accept?

A: T/T, L/C, Western Union etc.

Q6. What's the after-sale service?

A: We could negotiate then come to an agreement.

${currentPro.title}