EN

Language

All categories

Product ID: 68593016

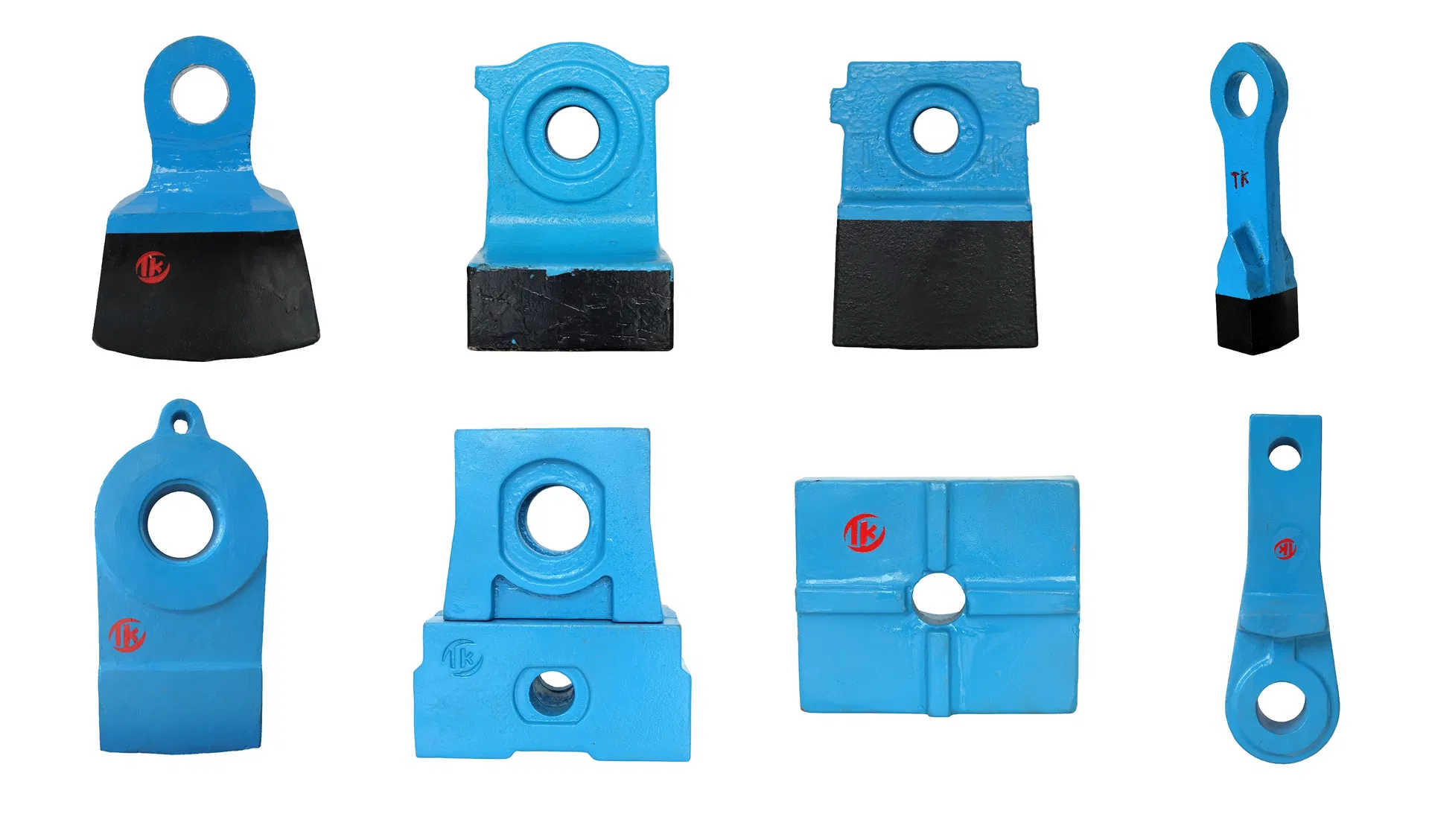

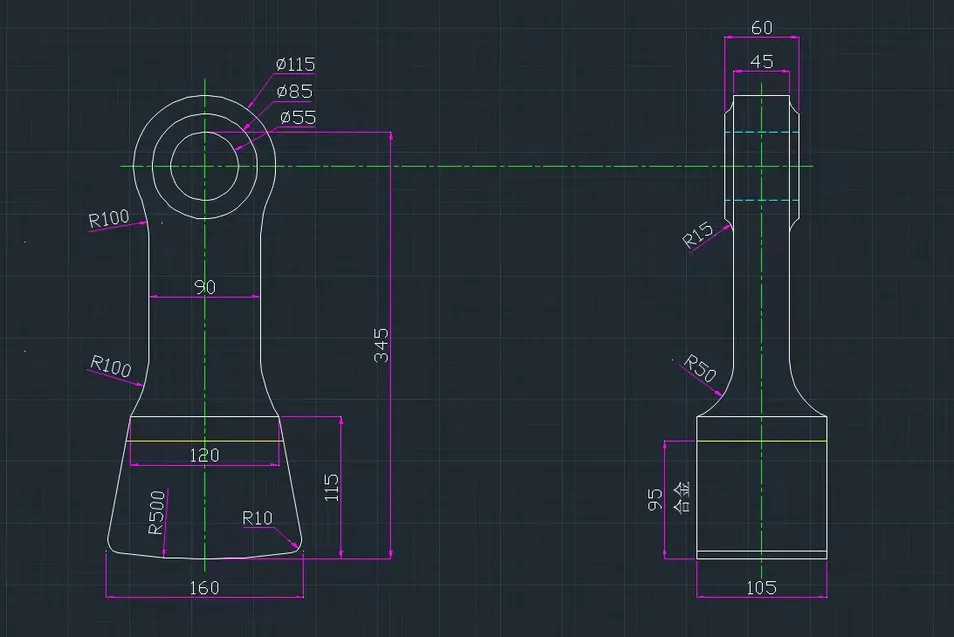

Wear-Resistant Ceramic Composite Hammer Heads for Ore Mining Crushers

Contact Now

Description

Basic Info.

Model NO.

JYMM 7

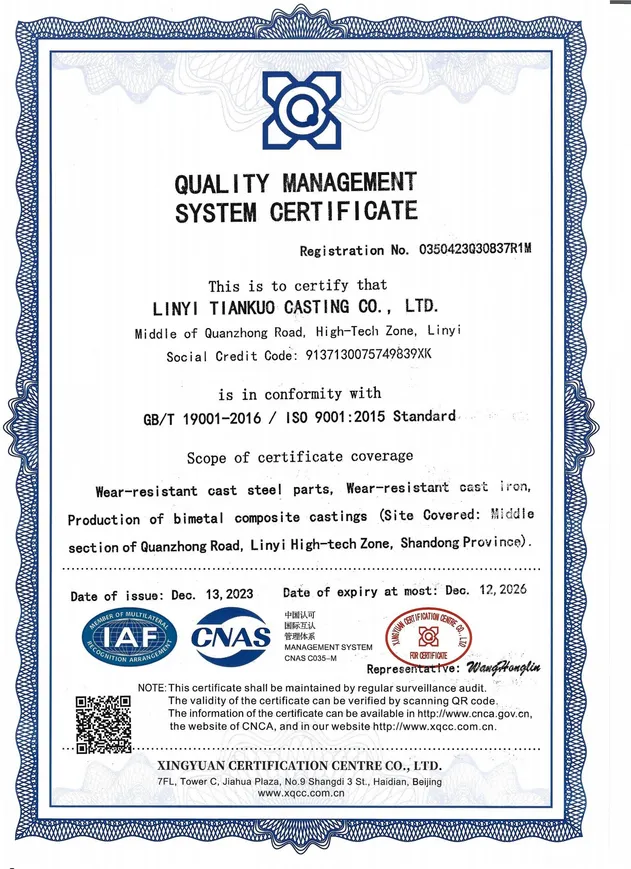

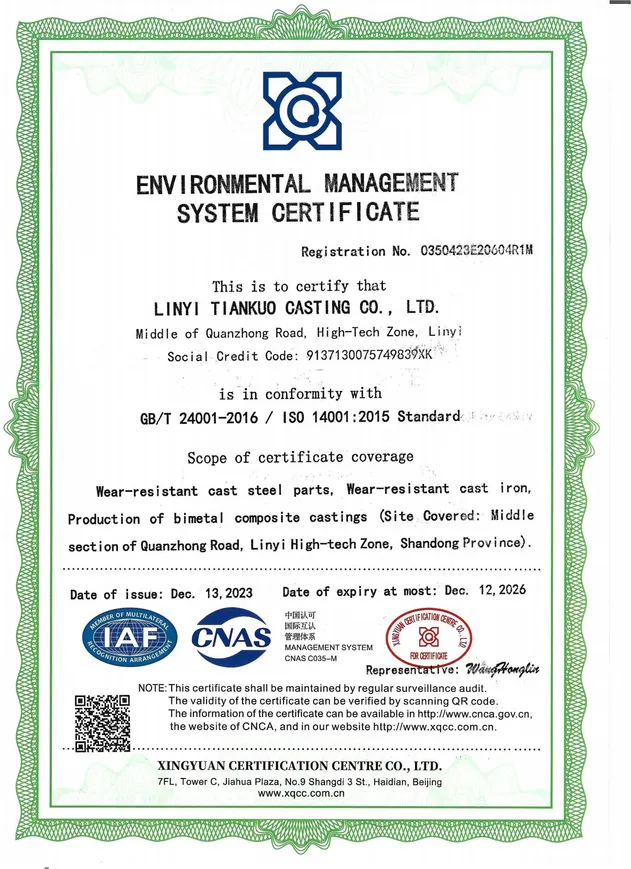

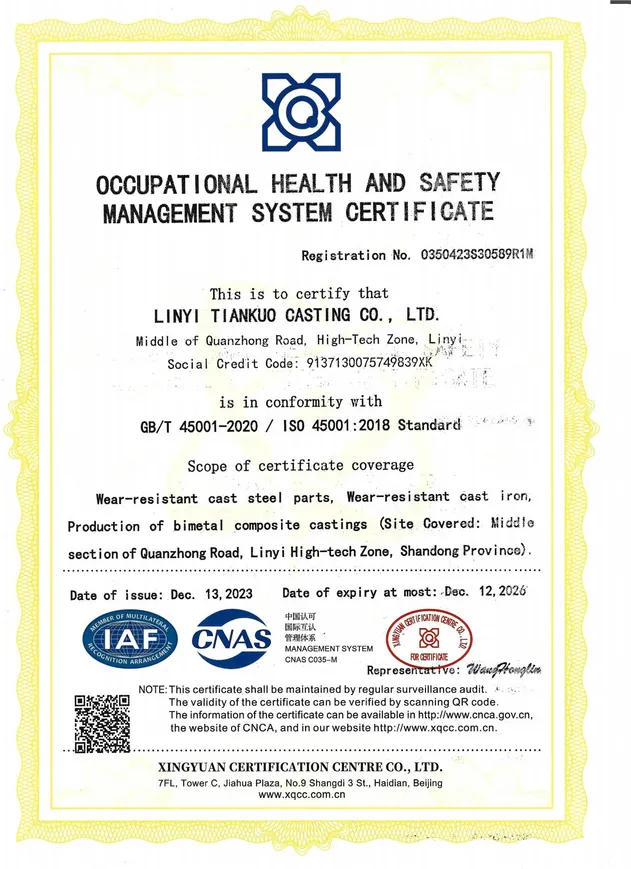

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Standard

AISI, ASME, BS, ANSI

Surface Treatment

Without Processing

Manufacturing Process

Casting

Material

Alloy Steel

Size

Customer Size

Condition

New

Use

Ore Mining

Delivery Time

According to The Quantity of Goods

Application

Hardware

OEM&ODM

Accept

Color

Light Gray / Customizable

Sand Core Type

Resin Sand Core

Structure

Casting

Advantage

Wear Resistant

After Services

Available

Model No.

Crusher Sand Machine Hammer Head

Steel Type

Alloy & Carbon

Materials

High Manganese Steel, etc

Quality

High Quality

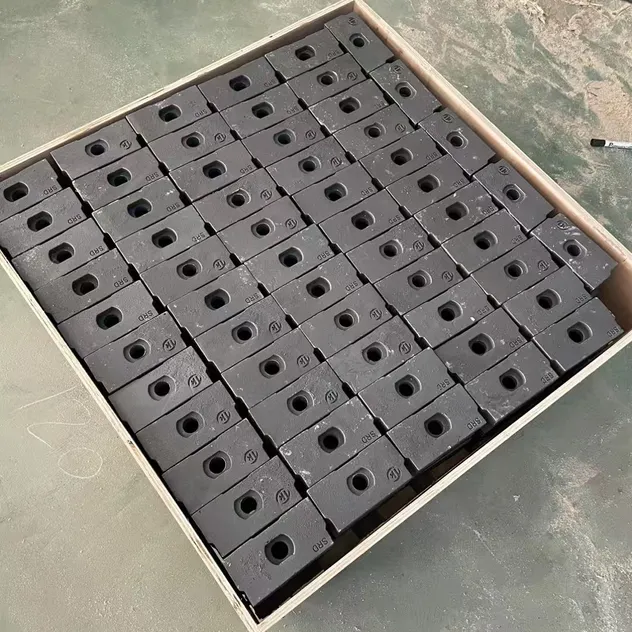

Transport Package

Pallets

Specification

350*130*1200 mm

Trademark

Yideli

Origin

Shandong, China

HS Code

8474900000

Production Capacity

50000 Pieces / Year

Product Description

Product Description

Quality choice

In stock supply

Support customization

From material selection to delivery,every program will be checked out layer by layer and the product quality will be tested

A strong after-sales team will help you with worries and difficulties , so that you can buy with confidence and use with peace of mind

The drawings and samples support personalized products , proof and confirm, and support a large amount of production

Specification

High chromium lining plate | ||||

Category | Impact toughness ak (J/cm2) | Rockwell hardness HRC | Microstructure | Performance |

Cr15 | ≥8 | ≥60 | M+M7C3+M23C6+A | suitable for mills below 3 m, with a service life of 3-5 years |

Cr20 | ≥8 | ≥60 | M+M7C3+M23C6+A | suitable for mills above 3 m, with a service life of 3-8 years |

Cr26 | ≥8 | ≥60 | M+M7C3+M23C6+A | suitable for mills above 4m, with a service life of 5-10 years |

Bimetallic compound lining plate | ||||

ZG45-Cr15 ZG45-Cr20 ZG45-Cr26 | composite style ≥25 J/cm2 | wear resistant layer ≥60 | soldering and casting iron in high temperature M+M7C3+M23C6+A | suitable for larger mills and equipment that will stand large impact loads,with a service life of 5-10 years |

Compound metallographic alloy steel lining plate | ||||

Alloy steel | ≥30 | ≥48 | M+B+A | suitable for mills of various specifications under dry and wet conditions,with good overall performance and a service life of 2-10 years |

Product Advantages

CRUSHER WEAR PARTS DESIGN EXPERTSE

We have established a full-cycle after-sales support system for breaker hammers to ensure efficient and stable equipment operation. During the warranty period, free replacement services are provided for hammer damages caused by non-human factors, eliminating customer worries. A 24/7 online response mechanism is in place - our customer service team stands by in real-time.

THE PROVEN QUALITY OF CRUSHER WEAR PARTS

Proactive after-sales care includes regular customer follow-ups to develop personalized maintenance plans based on hammer usage frequency and working conditions. Operational training and maintenance guidance are provided to extend equipment service life. With a complete spare parts supply chain, we maintain ample stock of original hammers and related components, supporting priority allocation for urgent orders to quickly respond to sudden customer needs and reduce production interruption losses. We safeguard customer value through professional services.

Product Spotlights

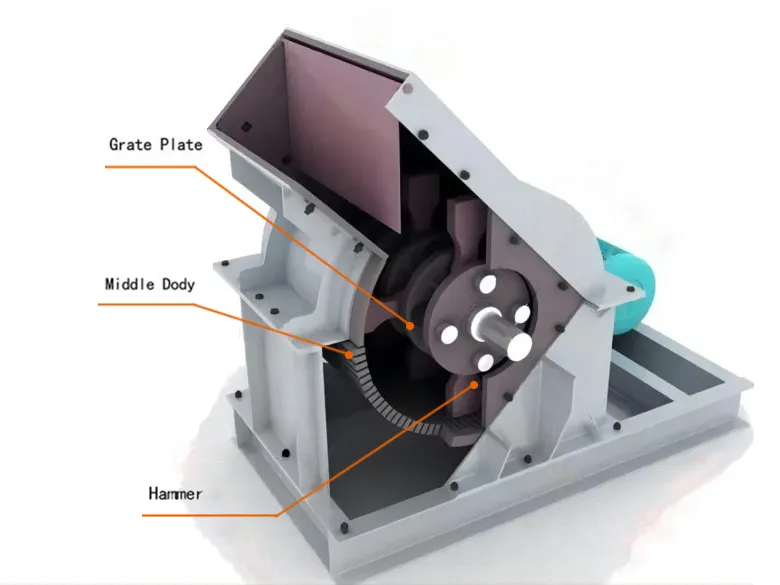

High-performance forged breaker hammer heads are made of high manganese steel and high chromium alloy to ensure durability and impact resistance in mining operations. Products undergo rigorous testing, including surface hardness, core hardness, chemical composition and impact tests, to provide reliable quality assurance. Certified mechanical test reports are provided to verify their performance standards.

Packing & Delivery

Advantages

1. High level of hardness and wear resistance, strongly supports carbide particles, prevents carbide from falling off the wear surface during work which ensures the high wear resistance of the material.

2. Could be widely used in the crushing plant of basalt, limestone, cement clinker, and other minerals. It is suitable for building materials industries such as brick factories, large and small stone factories, steel plants, coking plants, machine-made sand, cement plants, etc.

2. Could be widely used in the crushing plant of basalt, limestone, cement clinker, and other minerals. It is suitable for building materials industries such as brick factories, large and small stone factories, steel plants, coking plants, machine-made sand, cement plants, etc.

Company Profile

Jinan Yideli Mining Machinery Co., Ltd

Jinan Yideli Mining Machinery Co., Ltd (JYMM) was founded in 2001, focusing on the crusher industry. Its main products include crushers such as sand making machines, hammer crushers, jaw crushers, crusher accessories such as hammer heads, and crusher supporting equipment. JYMM is one of the drafting units of national standard, meriting of its leadership in bimetallic composite hammerhead. Aside, JYMM's series of products are widely used in metallurgy, building materials, electric power, mining and other industries. Inorganic ceramic sand binder molding shell technique was adopted by JYMM, and it also has fully equipped facilities, e.g. energy-saving steel shell intermediate frequency melting furnace, fiber trolley-type electric-resistance furnace, automatic core shooting machine etc. Moreover, JYMM possesses advanced physical and chemical characterization equipment, e.g. metallurgical microscope, spectral analyzer, high-frequency infrared carbon and sulfur instrument, desktop hardness tester and other imported facilities.

Our Customers

FAQ

Q : Are you a foundry or trading company ?

A: We a casting foundry since 2001, has been specializing in this industry for more than 20 years. We equip with complete facilities, all production process from manufacturing to testing is finished in our own foundry.

A: We a casting foundry since 2001, has been specializing in this industry for more than 20 years. We equip with complete facilities, all production process from manufacturing to testing is finished in our own foundry.

Q : What kind of products do you make ?

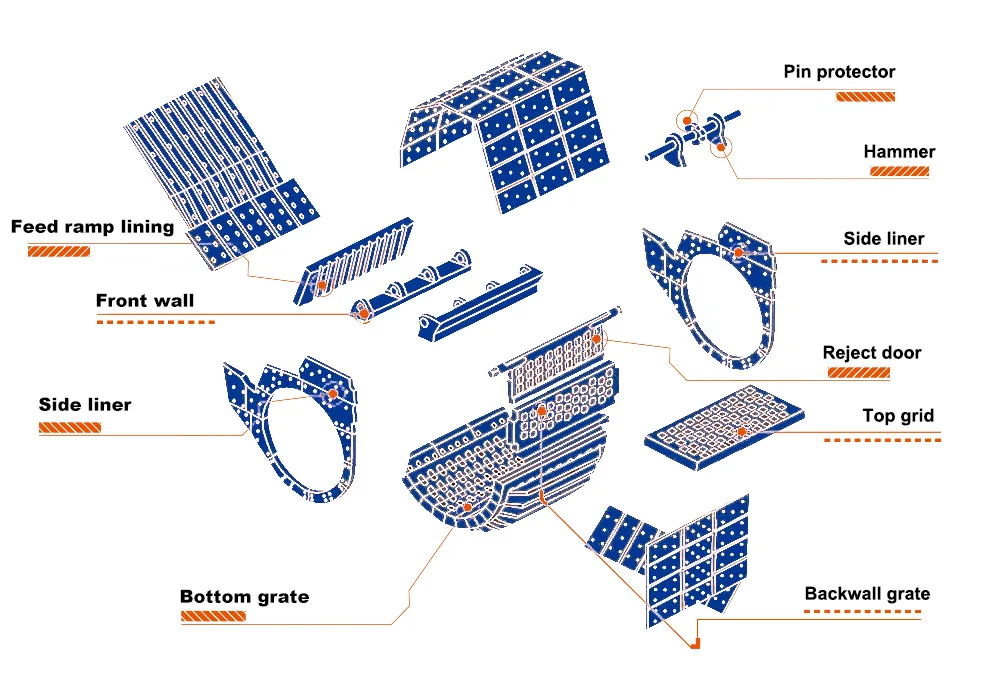

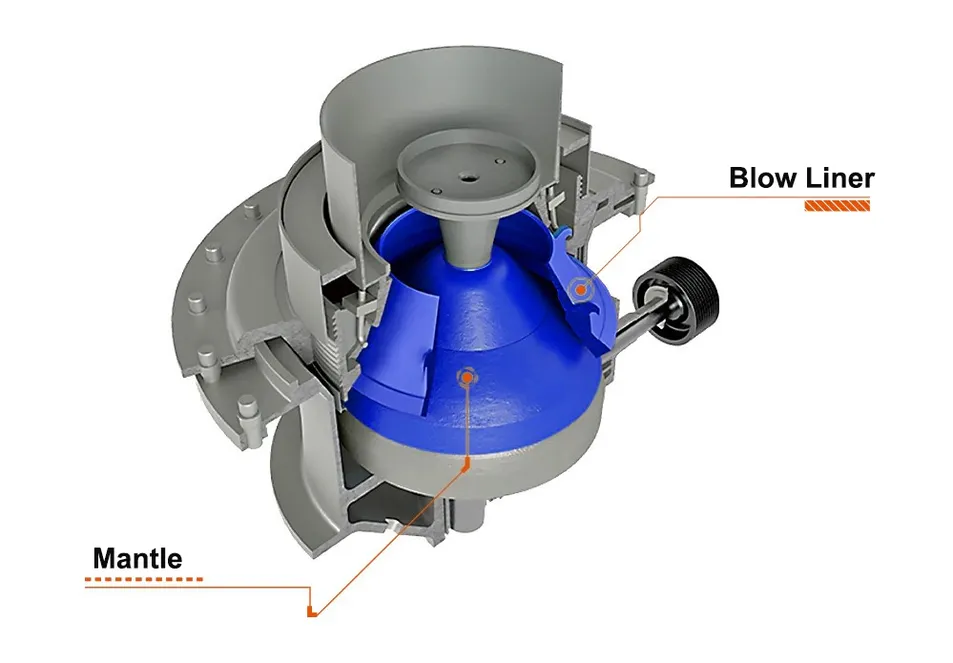

A: We specialize in mining machinery parts , shredder parts and excavator attachments such as jaw plates, concaves, mantles, bowl liners, mill liners, shredder hammers, grates, top gids, caps, track shoes, bucket teeth and more.

A: We specialize in mining machinery parts , shredder parts and excavator attachments such as jaw plates, concaves, mantles, bowl liners, mill liners, shredder hammers, grates, top gids, caps, track shoes, bucket teeth and more.

Q : What is your time of delivery ?

A : Our lead time is generally 15 days for existing patterns, 30 days for new patterns. Exact time to be finalized on receiving of finalized order.

Q : Do you offer the supporting service for technology and engineering ?

A : Yes. our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

A : Our lead time is generally 15 days for existing patterns, 30 days for new patterns. Exact time to be finalized on receiving of finalized order.

Q : Do you offer the supporting service for technology and engineering ?

A : Yes. our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

Contact Now

Please Send Message

${currentPro.title}