15/18mm MDF Slot Board T&G Board

Description

Basic Info.

- Model NO. DFW-SLOT MDF

- Finish Melamine Impregnated Paper

- Formaldehyde Emission Standards E1

- Usage Indoor, Outdoor

- Production Process Semi-Dry Process

- Size 1220*2440mm

- Thickness 15-25mm

- Certification CARB, CE

- Product Slotted MDF

- Glue E1/E2/E0

- Dimension 1220*2440, 1830*3660, 1830*2440

- MDF Size 1220*2440mm/1830*2440mm/1220*2800mm

- MDF Color Wood/Pine/Green or Customed

- Surface Surface

- MDF Density 730~750kg/M³

- Slot Numbers 7~15

- Aluminum 0.4~1mm

- Transport Package Strong Export Pallets

- Specification Cabinet standard

- Trademark DFW

- Origin China

- HS Code 4411149900

- Production Capacity 2500 Cubic Meters Per Month

Product Description

Product name: slotwall board / melamine slotted mdf board / display board

- Core: mdf

- Size: 1220*2440mm, 1220*1220mm

- Thickness: 15mm-25mm

- Glue: E1/E2

- Density: 700~750kgs/CBM

- Surface finish: Melamine paper faced

- Color: Various solid color/wood grains/magic/rose

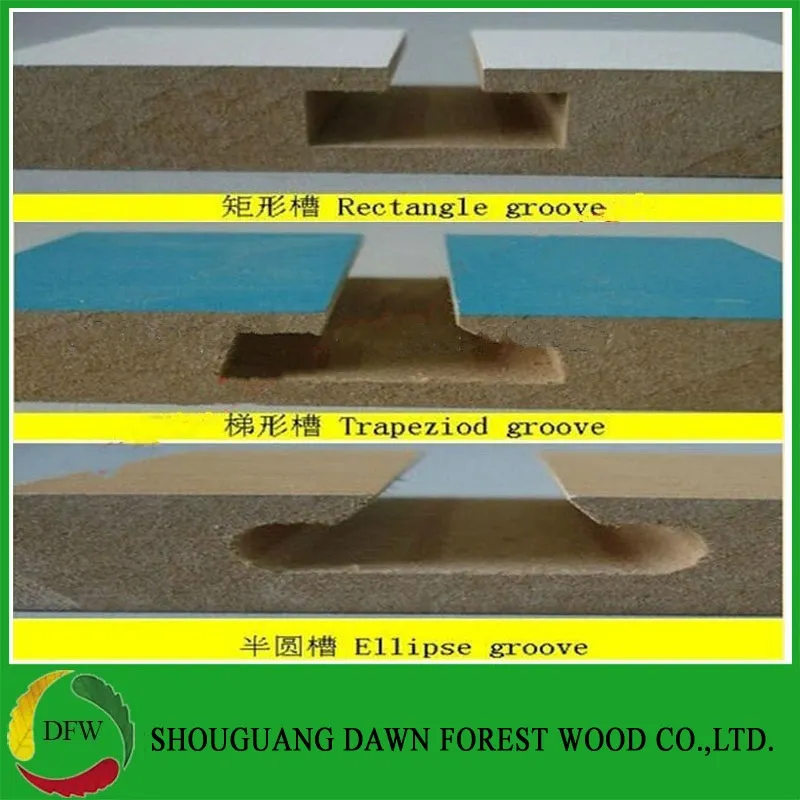

- Groove Nos. 7/9/11/12/17/19, or with two half groove, as your request.

- Usage: Decorative / market show / shop, etc.

- Main market: Middle east / Egypt / Iran / Africa / Europe / Asia

- Production capacity: 15000CBM/month

- Advantage: Fastest delivery time, best price, favorable service

Payment & Delivery

- Payment terms:

- 1. L/C at sight

- 2. 30% deposit in advance, balance against the copy of BL.

- Delivery time: 15-20 day after receive L/C or 30% T/T

- Loading port: Qingdao / Lian yungang

- Loading quantity:

- 1. Loose packing: for example, 15mm: 570PCS/20GP 18mm: 500PCS/20GP

- 2. Pallets packing: Carton fasten with steel belts, 8 pallets/20GP. 16 Pallets/40GP. 18 pallets/40HQ. 900mm height/pallets.

Product Show

Application

Usage

- 1. It is used for furniture making, such as shop-fitting, display rack, storage cabinet, garage cabinet.

- 2. It is directly used for display board in retail stores and supermarkets.

Feature

- 1. Easy assembling, easy operation, bearing and tightly.

- 2. Compatible with standard slatwall accessories. All kinds of specifications applicable to different product and market demand.

- 3. Strong and Durable.

- 4. Water and moisture resistant, easy to clean.

- 5. Smooth Satin finish gives high-end aesthetic appeal.

- 6. Scratch resistant with normal use, surface scratches can be easily repaired and are less noticeable because the material color is throughout product.

Our Service

- 1. Your enquiry related to our product & price will be replied within 24 hours.

- 2. Free sample are available.

- 3. Well-trained & experienced staff are to answer all your inquires in English of course.

- 4. Your business relationship with us will be confidential to any third party.

- 5. Good after-sale service offered, please get back if you go question.

Our Company

Shouguang Dawn Forest Wood Co., Ltd: Located in Shandong Shouguang city, established in 2005, is a collection of particle board production and all kind of melamine board and panel furniture production and processing. Created more than 10 years, the company always be in line with business philosophy of "strives for the survival by the quality and in good faith to win Customers", successfully sell products around the world and deeply trusted by customers. In recent years, there are rapid growth in production and sales of panel furniture particularly, the main products include kitchen Furniture, wardrobe, tea table, TV cabinet, display cabinet, shoe cabinet and desk etc. The main materials of panel furniture is man-made board, PVC edge banding, and hardware include hinge, slide rail, nails, wooden falcon, etc. Panel furniture, due to convenient installation, can tear open outfit, economic environmental loved by masses of users. Originated in Germany, developed in China, production volume increased year by year in China. And also exported to all over the world. Welcome friends around the world to visit our factory.

Company Advantage

QC of Quality

Two time inspection and All the products best quality. Our professional QC inspectors are more than 10 years in plywood production and QC field

- One: In the production process, prepare core material, joint core, glue, hot press, cold press, sanding, covered veneer, deal with edges etc

- Second: Packing and Loading. Checked the details of quality, dimension tolerance, thickness tolerance, bonding quality, core layers and structure, smooth of face, rejects defects of veneer, color difference, split of veneer, lack of core etc.

We control quality as your order requirements, then save your time and cost.

Advanced equipment

Imported Italy and Germany sanding machine

Production of capacity

6000 cbm/month

Delivery time

15 days after order confirmed

Competitive Price

Lowest price, superior quality, prompt shipment, best service!

Waiting For Your Calling:

Cherry

Mobile: +86-18363662482

${currentPro.title}