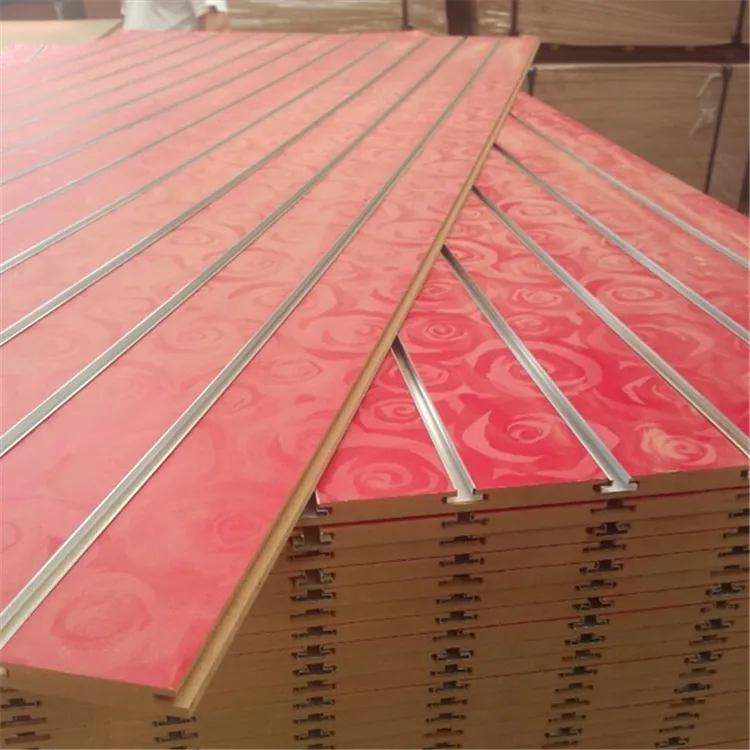

Slot Grooved MDF Board with 11 Aluminium Strips

Description

Basic Info.

- Model NO. 4x8ft

- Material Wood Fiber

- Type MDF / Semi-hardboards

- Finish Veneer

- Formaldehyde Emission Standards E0

- Usage Indoor, Outdoor

- Production Process Semi-Dry Process

- Size 1220*2440mm

- Thickness 12mm 15mm 18mm

- Name MDF

- Face Wood Veneer

- Glue E2 E1 E0

- Mositure Usually 8%

- Density 600-750

- Color White, Yellow

- Wood Poplar/Pine

- Tolerance 0mm

- MOQ 20FT

- Grade E0 E1 E2

- Customize Customize Size and Color

- Melamine Melamine Paper or UV Coated

- Cutting Service Yes

- Package Pallet

- Strength High Grade

- Transport Package Standard Exported Pakage

- Specification SGS Grade AA

- Trademark Lisen wood

- Origin China Linyi City

- HS Code 4412321090

- Production Capacity 8000 Cbm Each Month

Product Description

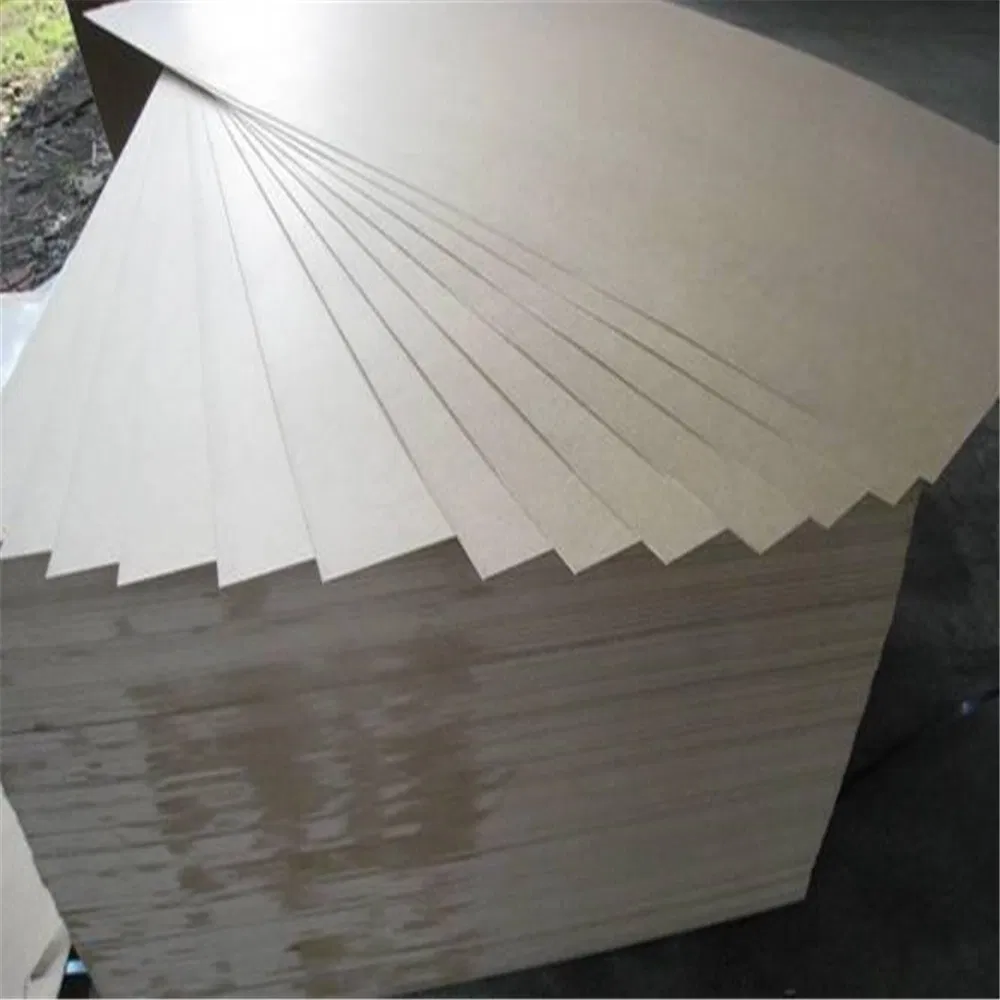

Raw/Plain Faced MDF panel

- Thickness 2.0mm - 30mm or as request Melamine Slotted MDF

- Size 9mm -30mm: 1220*2440m, 1830*2440mm, 1830*2745mm, 1830*3660mm

- 3mm - 8mm: 1220*2800mm, 2200*2800mm, 2100*2500mm, 2400*2800mm

- Materials poplar or polar and hardwood combi

- GLue E1, E2,E0

- Density 820-830 kg/m3 for 2mm- 6mm

- 730-740 kg/m3 for 9mm-30mm

- Color light brwon, dark brown

- surface 2mm-6mm unsanded or sanded by 180

- 7mm-30mm sanded by 180

- Usage furniture and decoration, such as table, cabinet, chest, etc.

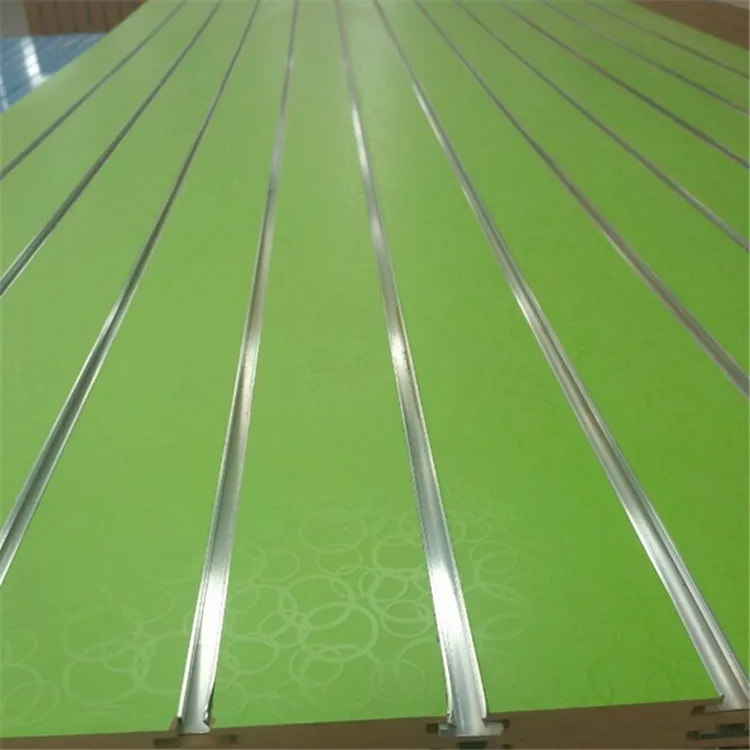

GREEN COLOR HMR MDF (HIGH MOISTURE RESISTANT MDF)

- Size 1220*2440mm

- Thickness 12mm, 15mm, 18mm

- Color Green Color

- Density 800 kg/m3

- swelling rate in water less than 6%

- grade E1, E2, E0

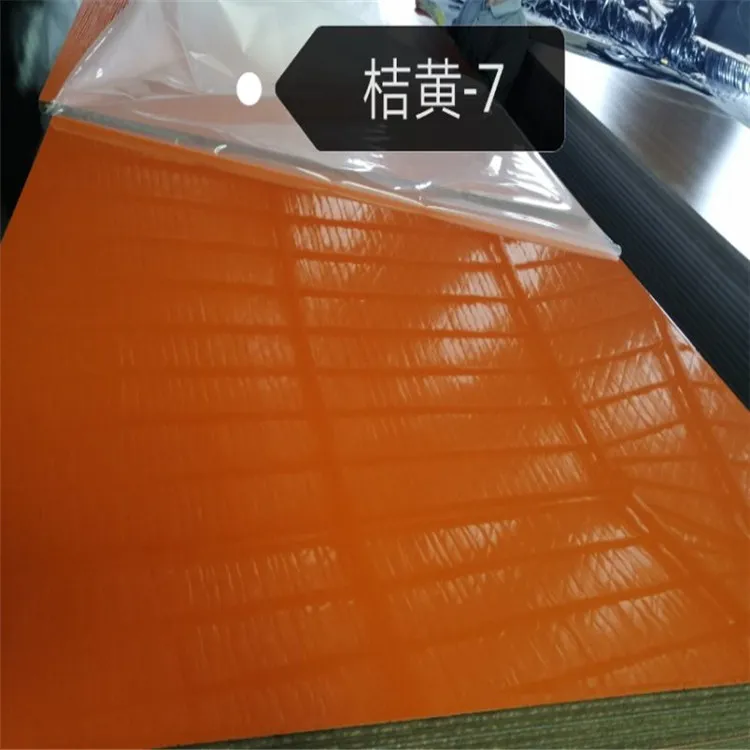

MELAMINE FACED MDF panel

- size 1220*2440mm, 1830*2440mm,1830*2745mm

- thickness 2.0mm- 30mm

- finished matt, smooth, glossy, high glossy, embossed, ect.

- Color solid or pure color, wood grain color

SOTTED MDF /WALL PANEL MDF

- Size 1220*2440mm

- Thickness 15mm, 18mm

- Slots rectangle, trapezium

- Insert Alum insert, plastic Insert

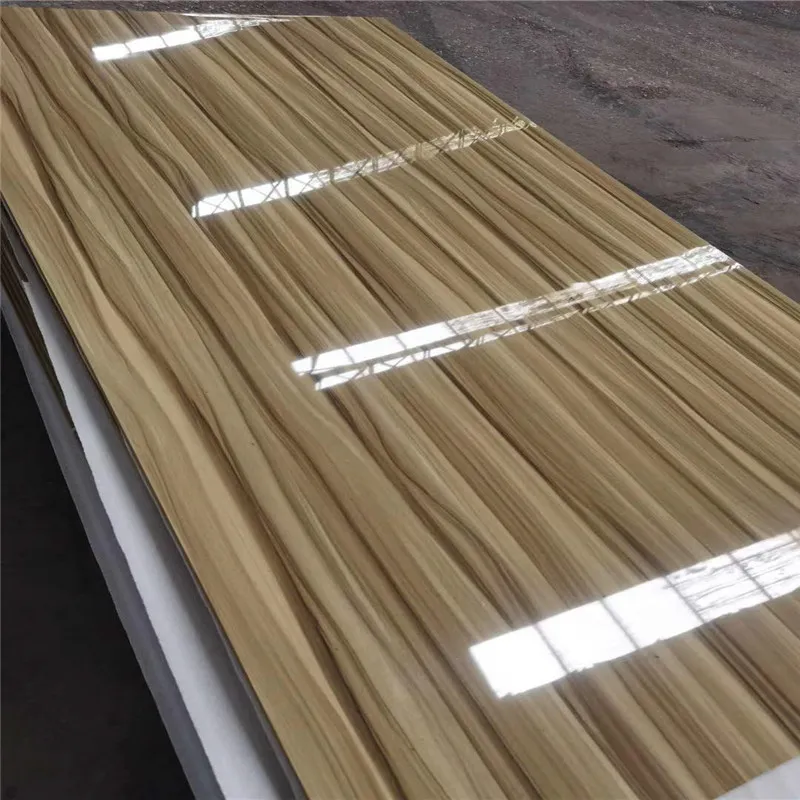

NATURAL VENEER LAMINATED MDF

- SIZE 1220*2440MM

- Thickness 2.0MM-30MM

- Finished ONE SIDE OR TWO SIDES AS REQUEST

- veneer species beech, oak, maple, walnut,

Technical Data:

| No. | Test Items | Technical Specification | Unit | Test Result |

|---|---|---|---|---|

| 1 | Moisture Content | 4~13 | % | 5.8 |

| 2 | Density | 550~880 | Kg/m3 | 730 |

| 3 | Density Tolerance | ±7.0 | % | ±1.4 |

| 4 | Expansion ration in thickness due to water absorption | ≤10 | % | 8.8 |

| 5 | Internal bonding | ≥0.45 | Mpa | 0.49 |

| 6 | Modulus of rupture | ≥20 | Mpa | 26.8 |

| 7 | Modulus of elasticity | ≥2200 | Mpa | 3280 |

| 8 | Screw holding | Face≥1000 | N | 1120 |

| Side≥800 | 870 | |||

| 9 | Surface bonding | Mpa | 1.28 | |

| 10 | Formal Dehyde Emission | E1: ≤9.0 | mg/100g | 4.9 |

| E2: ≤30.0 | 20 |

Plain MDF board with different Thickness

Packaged MDF board

Melamine MDF board

UV MDf board

Package

Packing Details:

The bottom is strong pallets with one sheet of protected board which is MDF or Particle board and thickness is not less than 15mm. All the goods are wrapped by plastic bags avoiding any moisture. The top and four sides with one sheet of protected board which is not less than 4mm MDF or 8mm Particle board. Then all the goods are strengthened by steel strips. The details as the following pictures

Advantage

- Uniform plate density, excellent physics performance; It's close to natural wood but better than natural plank.

- High strength and good dimensional stability, thickness is 2.5mm-30mm, it has been widely used.

- Good mechanical processing performance, It may use natural wood processing equipment and methods for machining.

- Flat surface, so It is easy for secondary processing.

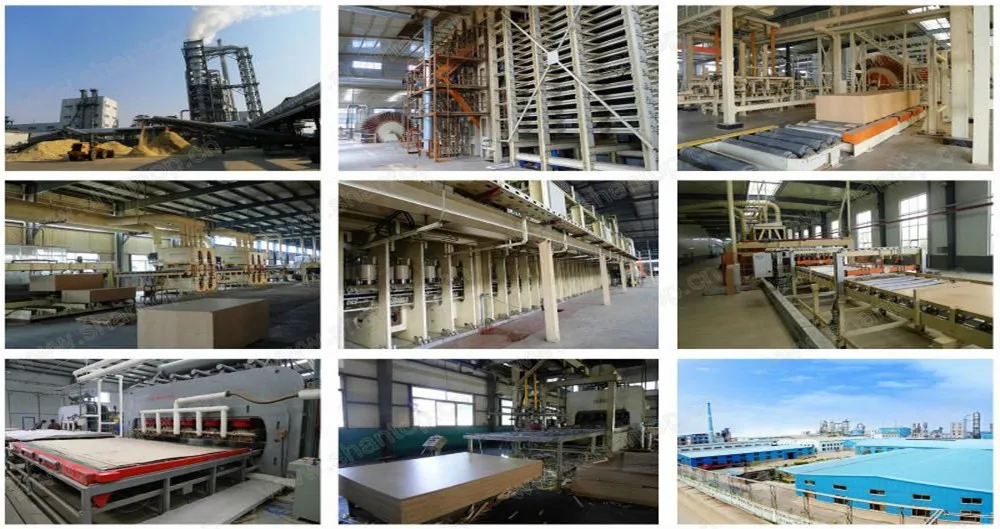

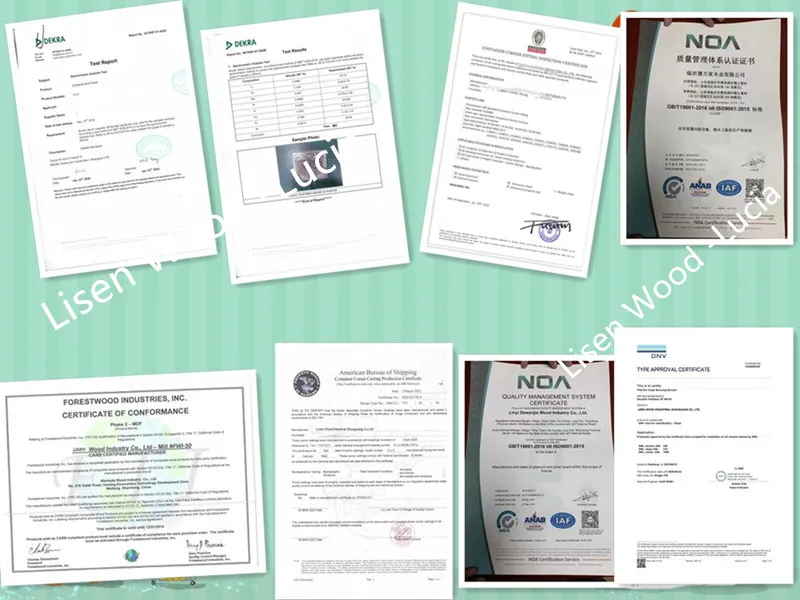

About us:

(1) Our company has specialized in wood products more 15 years.

(2) We have more than 200 workers and technician workers with much experience.

(3) The capacity of our factory is 3500-5000 CBM per month.

(4) We have many big markets more than 20 countries and regions...Main markets are from Middle East, America, Australia, Germany and Africa etc.

The reson to chose our company:

- Professional plywood manufacturer

- Have 8 years produce experience

- We are honor credibility

- High quality with competitive price

FAQ:

- May I know what about the material of construction plywood?

- Plywood Reuse time

- Where is you company?

- Which airport is nearest to your factory?

- What is your delivery time and payment term?

It's Poplar,Hardwood,Birch and so on.

Different quality can use different times,different from 2-35 times.

We locate in Linyi city, Shandong province,China.

Qingdao Port

Delivery time about 15 days after your deposit or L/C at sight

T/T or L/C at sight.

Need More Information?

Please Send Me Inquiry

Contact person: Lucia zhao

${currentPro.title}