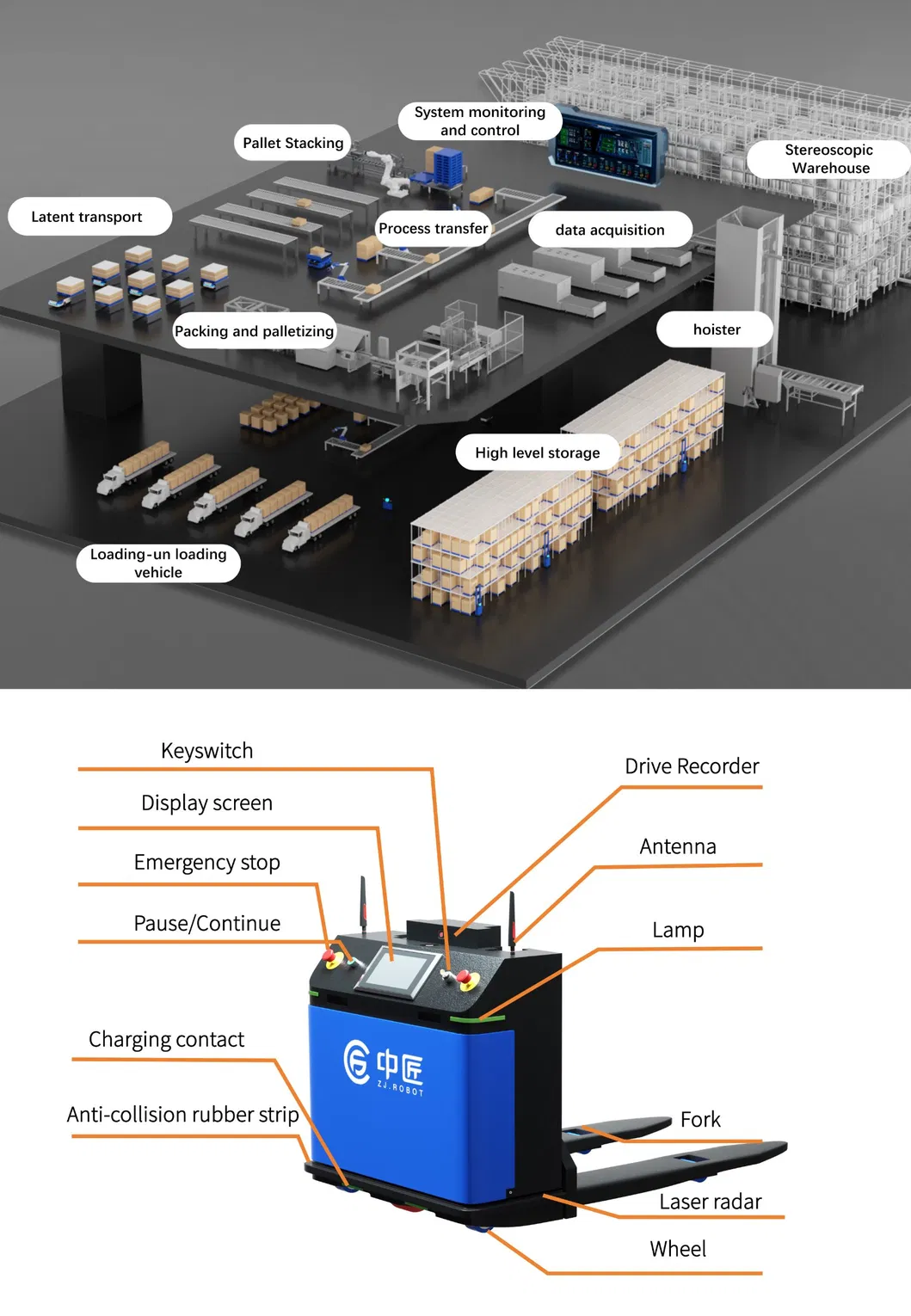

Customized AGV Automatic Navigation Forklift Manufacturer

Description

Basic Info.

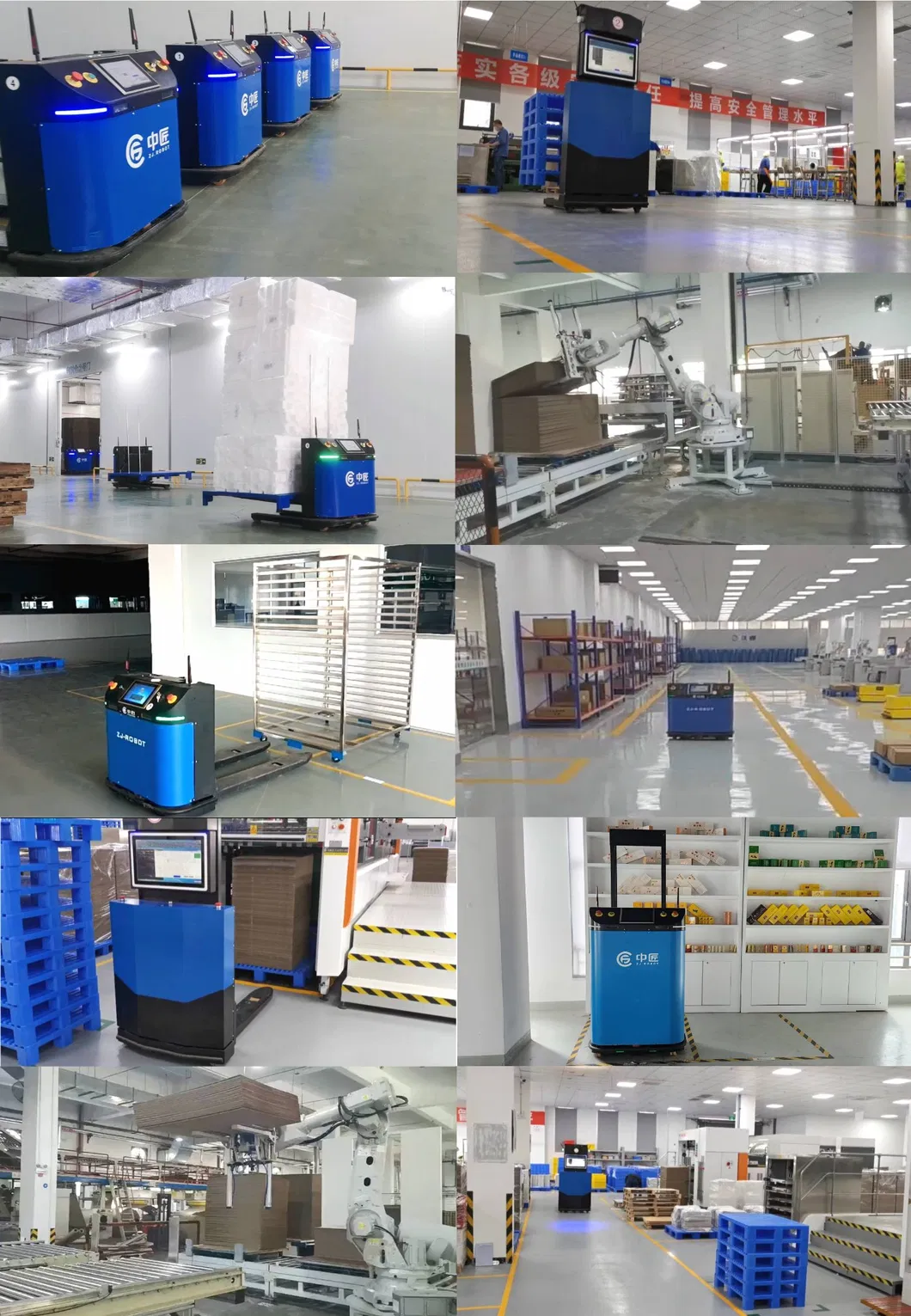

- Drive Mode: Electric

- Payload Capacity: 1000 kg

- Colour: Blue (Customizable)

- Load: 100kg~2000kg

- Size: Customizable

- Protection Scope: 360°

- Condition: New

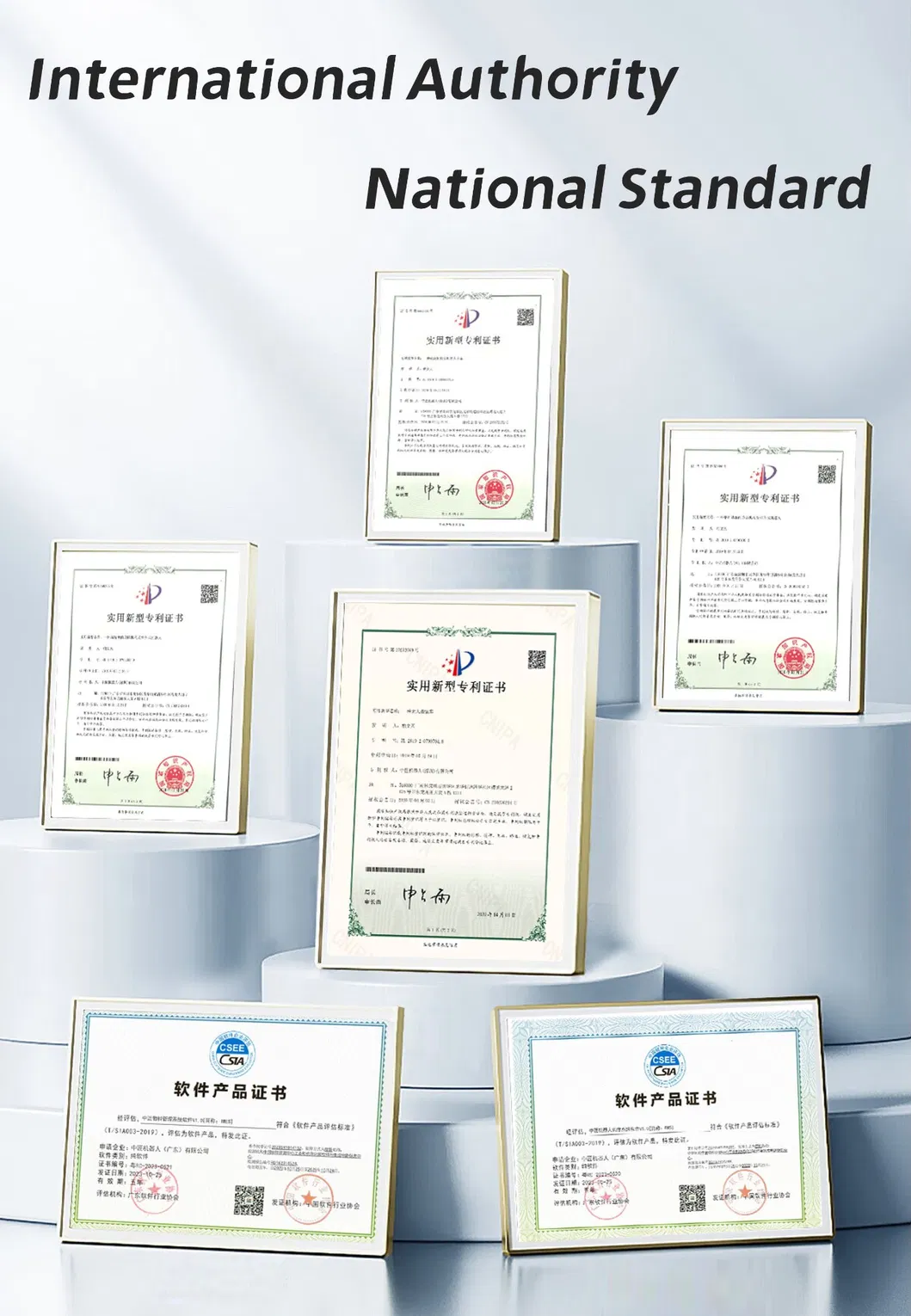

- Certification: ISO, CE

- After-Sales Service: Factory Supplied

- Warranty: 1 year

- Transport Package: Carton Packaging

- Trademark: Customized or ZJ Robot

- Origin: China

- Production Capacity: 1000 PCS/Year

Product Description

Fourth generation navigation technology: Vision navigation

Navigation mode

- Magnetic stripe / ribbon-based navigation

- Laser navigation

- QR code navigation

- QR code navigation

Module costs

- Low

- High

- Low

- Low

Signpost

- Magnetic stripe / ribbon

- Reflector panel

- QR code

- Paper label

Modification of the site environment

- Lay magnetic stripes / ribbons (All tracks)

- Installation of reflector post

- Paste the QR code

- Paste labels on the ceiling

Aisle / storage bin occupation

- No space occupied

- Space occupied

- No space occupied

- No space occupied

Signposting costs

- High

- Relatively high

- Relatively good

- Low

Route planning flexibility

- Poor

- Excellent

- Fair

- Excellent

Wear and maintenance

- Prone to wear and tear, high maintenance costs

- Low wear and tear, low maintenance costs

- Prone to wear and tear, high maintenance costs

- Maintenance-free

Subsequent path changes

- Re-lay magnetic stripes / ribbons

- Re-lay reflector panel (No change required if no aisles are added)

- Re-post the QR code

- Relabel (No change required if no aisles are added)

Other

- The maximum lifting capacity is 3000kg

- The size and color of robot can be customized per customer's requirement.

- All exported AMR handling robots are equipped with maintenance free integrated drive wheels, which are only replaceable and not repaired.

- Customers need to ensure a stable WIFI signal to prevent disconnection

- Delivery time: about 70 natural days after order confirmed.

- We will provide test videos at the time of delivery.

Maximum Protection ≥ 10m. Truly 360° Safety Protection

Multiple safety mechanisms ensure the safety of operators and robots during operation. The robot itself comes with various safety protection measures, including emergency stop, obstacle avoidance, collision protection, sound and light alarm module, etc.

Service process

- Automatic equipment and systems Development of automation infrastructure

- Heterogeneous systems convergence standard Setup of the whole plant system

- Equipment interconnectivity IOT path development

- Digitization of the production process Full-cycle data building

- Networking of management processes Networked operation construction

Corporate Profile - Company introduction

ZJ Robot is a provider of one-stop solutions for the vertical industry of smart factories, with the proprietary systems of intelligent warehousing, logistics, and production management at its core.

Multi-dimensional technology integration

- Intelligent Equipment

- Smart Factory

- Smart Hardware

- Detection And Monitoring

- Information System

Independent R&D of crucial technologies

- Control algorithm

- Production management system

- Core equipment design and production

- Navigation algorithms

- Scheduling system

- Structural design

- Tools software

In-depth cooperation and long-term service

- Customized plan

- Stepwise implementation

- Push forward in three dimensions

- System development

Overall in-depth cooperation and standing at the high starting point to promote digital transformation

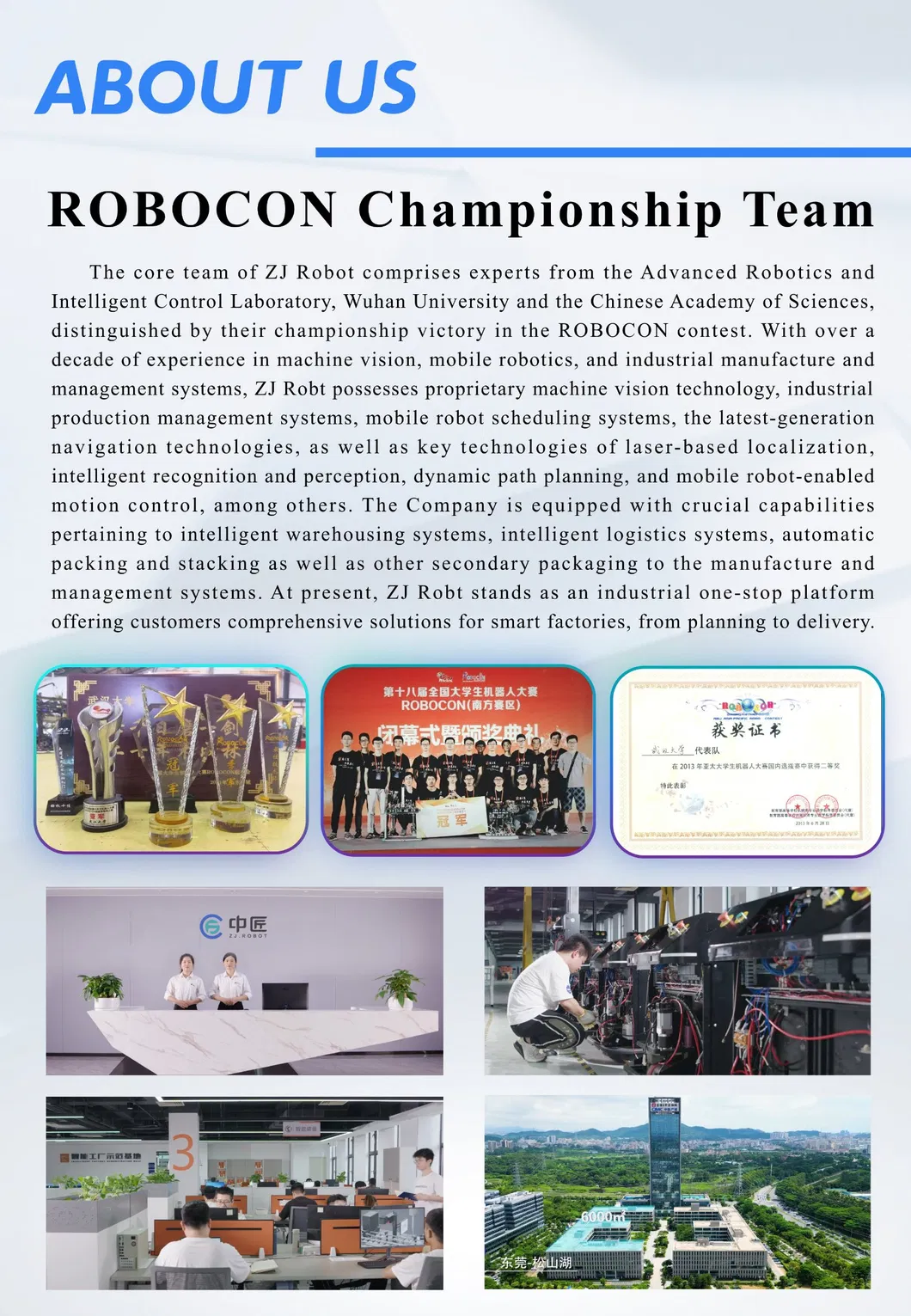

ABOUT US -- ROBOCON Championship Team

The core team of ZJ Robot comprises experts from the Advanced Robotics and Intelligent Control Laboratory, Wuhan University and the Chinese Academy of Sciences, distinguished by their championship victory in the ROBOCON contest. With over a decade of experience in machine vision, mobile robotics, and industrial manufacture and management systems, ZJ Robot possesses proprietary machine vision technology, industrial production management systems, mobile robot scheduling systems, the latest-generation navigation technologies, as well as key technologies of laser-based localization, intelligent recognition and perception, dynamic path planning, and mobile robot-enabled motion control, among others. The Company is equipped with crucial capabilities pertaining to intelligent warehousing systems, intelligent logistics systems, automatic packing and stacking as well as other secondary packaging to the manufacture and management systems. At present, ZJ Robot stands as an industrial one-stop platform offering customers comprehensive solutions for smart factories, from planning to delivery.

Q&A

- Q: Can I purchase products which are not shown on the website?

- A: Yes. Please send us your detailed requirements and we will try to help with your specific needs.

- Q: How can I place an order?

- A: You can contact us by email (see contact page).

- Q: Where do you loading the goods?

- A: Shenzhen port, etc.

- Q: How long is the warranty of your products ?

- A: Generally, it's one-year-warranty. During the warranty period, we offer you free maintenance.

- Q: After-sale service

- A: Before delivery, customers can choose on-site inspection or video inspection, export wooden box packaging, 24/7 after-sales online service, and engineers can also be arranged to provide service at the customer site.

- Q: Payment

- A: Our payment is T/T, Paypal, West Union, Trade Assurance (Ali pay or E-check), L/C, and D/P.

${currentPro.title}