2XL-1115 Series Spiral Sand Washer for Industrial Use

Description

Introducing the XL 1115 Industrial Sand Washing Machine, a high-performance spiral washer designed for efficient sand processing in demanding industrial environments. This advanced equipment is specifically engineered to handle large volumes of sand, ensuring optimal cleaning and separation of impurities. The XL Series offers a reliable solution for industries that require consistent quality and efficiency in their sand processing operations.

The XL 1115 is part of the XL Series, a range of industrial sand washing machines known for their durability, precision, and ease of maintenance. Whether you are working in construction, mining, or manufacturing, this spiral washer for sand processing provides an effective way to produce clean, high-quality sand suitable for various applications. Its robust design and innovative technology make it a preferred choice among professionals looking for a dependable and efficient sand washing solution.

One of the key features of the XL 1115 is its spiral washer design, which ensures thorough cleaning by agitating the sand and removing unwanted particles such as clay, silt, and debris. This process enhances the overall quality of the sand, making it more suitable for use in concrete production, road construction, and other industrial applications. The machine's efficient water usage and low energy consumption further contribute to its cost-effectiveness and environmental sustainability.

Constructed with high-quality materials, the XL 1115 is built to withstand harsh operating conditions and deliver long-lasting performance. Its sturdy frame and corrosion-resistant components ensure reliability even in challenging environments. Additionally, the machine is designed with user-friendly controls and easy access points, making maintenance and operation straightforward for operators of all skill levels.

The XL 1115 is ideal for a wide range of applications, including but not limited to sand processing plants, aggregate production facilities, and material recycling centers. It is particularly useful in scenarios where large quantities of sand need to be cleaned and prepared for further processing. Its versatility allows it to be integrated into existing systems or used as a standalone unit, offering flexibility to meet different operational needs.

Users who have implemented the XL 1115 in their operations have reported significant improvements in sand quality and processing efficiency. Many have praised its ability to consistently deliver clean sand while minimizing downtime and maintenance requirements. The machine's reliable performance and durable construction have also been highlighted as major advantages, making it a valuable asset in any industrial setting.

When considering the XL 1115 Industrial Sand Washing Machine, it is important to understand its role in the broader context of sand processing. As a spiral washer industrial sand, it plays a crucial role in preparing raw sand for use in various industries. Its ability to remove contaminants and improve the purity of the final product makes it an essential component in many production lines.

For those looking to enhance their sand processing capabilities, the XL 1115 offers a proven solution that combines efficiency, reliability, and performance. Whether you are operating a small-scale facility or managing a large industrial site, this machine can help you achieve your production goals with minimal effort and maximum results.

Overall, the XL 1115 Industrial Sand Washing Machine is a top-tier option for anyone in need of a high-quality spiral washer for sand processing. With its advanced features, durable build, and exceptional performance, it stands out as a leading choice in the industry. By investing in this machine, you are not only improving your sand processing outcomes but also ensuring long-term value and satisfaction.

Common questions about the XL 1115 include inquiries about its capacity, maintenance requirements, and compatibility with different types of sand. The machine is designed to handle a variety of sand types, making it a versatile solution for different applications. Regular maintenance, such as checking the drive system and ensuring proper water flow, helps maintain optimal performance over time. Additionally, the machine's modular design allows for easy upgrades and modifications to suit evolving operational needs.

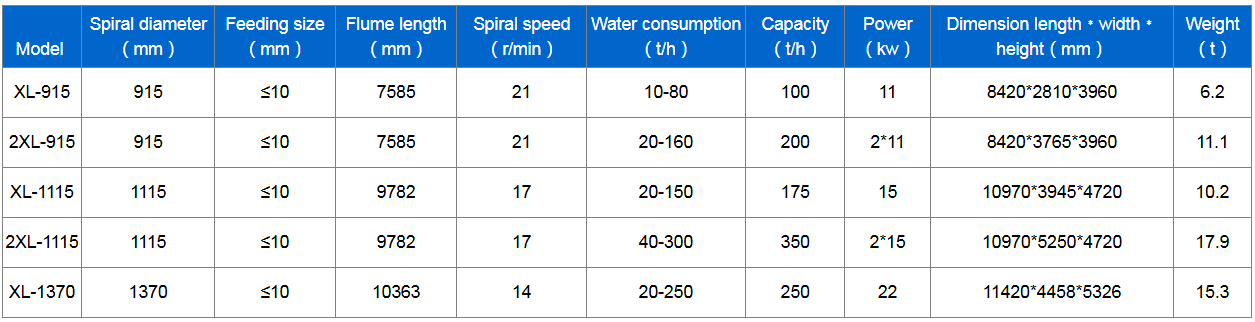

Technical data

${currentPro.title}