the NP1313 Impact Crusher

Description

Product Category: N-Series. Product Keywords: N Series NP1520 Impact Crusher, Crusher for Material Processing, Impact Crusher Unit. The N Series NP1520 Impact Crusher is a high-performance crushing unit designed for efficient material processing in various industrial applications. This impact crusher unit is engineered to handle a wide range of materials, including stone, concrete, and other hard substances, making it an essential tool for construction, mining, and recycling operations. With its robust design and advanced technology, the N Series NP1520 ensures reliable performance and long-term durability.

The N Series NP1520 Impact Crusher offers several key features that set it apart from other crushing units on the market. Its powerful motor provides consistent energy output, allowing for efficient reduction of large-sized materials into smaller, manageable pieces. The unit's durable rotor and impact plates are constructed from high-quality steel, ensuring resistance to wear and tear even under heavy usage conditions. Additionally, the crusher includes a user-friendly control system that allows operators to adjust settings easily, optimizing the crushing process for different types of materials.

This impact crusher unit is ideal for use in environments where continuous operation and high throughput are required. Whether it's for processing raw aggregates in construction sites or breaking down waste materials in recycling facilities, the N Series NP1520 delivers exceptional results. The design of the unit ensures minimal downtime, with easy access to critical components for maintenance and repairs. Its compact size also makes it suitable for installation in tight spaces without compromising performance.

The N Series NP1520 Impact Crusher is widely used in a variety of industries, including but not limited to construction, mining, and material recycling. In construction, it is employed to crush rocks and debris, providing the necessary aggregate for road building and foundation work. In mining, the unit helps in processing ores and minerals efficiently, contributing to the overall productivity of the operation. For recycling centers, this impact crusher unit plays a vital role in breaking down construction waste and other materials, facilitating their reuse and reducing environmental impact.

Users have praised the N Series NP1520 Impact Crusher for its reliability, efficiency, and ease of operation. Many operators report that the unit significantly improves their workflow by reducing the time needed to process materials. The consistent quality of the crushed output has also been highlighted as a major advantage, ensuring that the final product meets industry standards. Furthermore, the unit's low maintenance requirements and long service life have made it a popular choice among professionals in the field.

When considering the purchase of an impact crusher unit like the N Series NP1520, it is important to understand the specific needs of your operation. Factors such as the type of material being processed, the desired output size, and the volume of material to be handled should all be taken into account. The N Series NP1520 is well-suited for both small-scale and large-scale operations, offering flexibility and adaptability to different working conditions. Its ability to handle a wide range of materials makes it a versatile solution for various industrial applications.

For those looking for a durable and efficient crushing solution, the N Series NP1520 Impact Crusher is an excellent choice. It combines advanced engineering with practical design to deliver outstanding performance in demanding environments. Whether you are involved in construction, mining, or material recycling, this impact crusher unit can help streamline your processes and improve overall efficiency. Its proven track record and positive user feedback make it a valuable asset for any industrial operation requiring reliable material processing equipment.

Common questions about the N Series NP1520 Impact Crusher include inquiries about its power requirements, maintenance schedule, and compatibility with different materials. The unit operates on standard electrical systems, making it easy to integrate into existing setups. Regular maintenance, such as checking the wear parts and lubricating moving components, ensures optimal performance and extends the lifespan of the machine. The impact crusher is compatible with a wide range of materials, including but not limited to gravel, limestone, and recycled concrete, making it a flexible option for various applications.

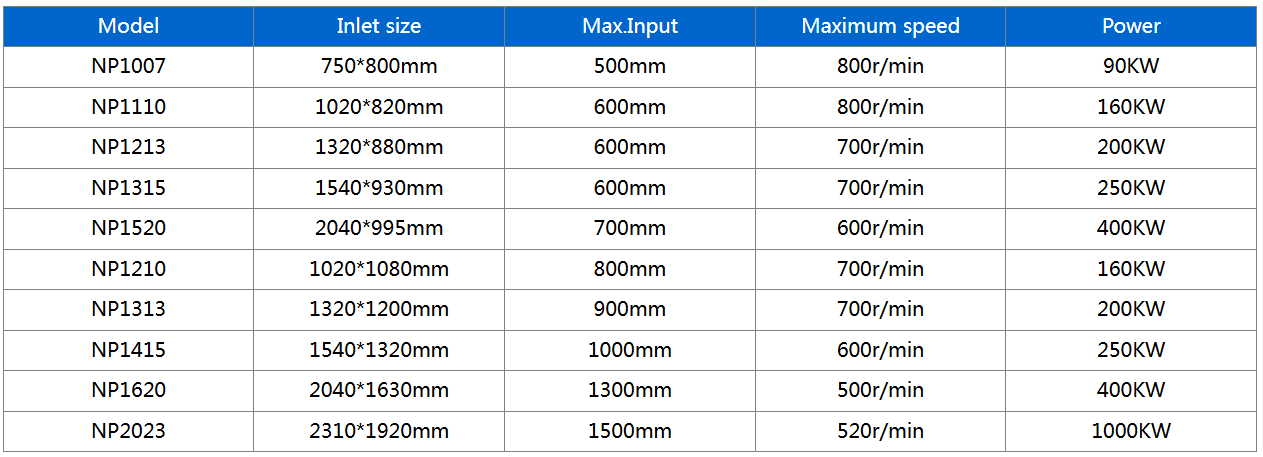

Technical parameter:

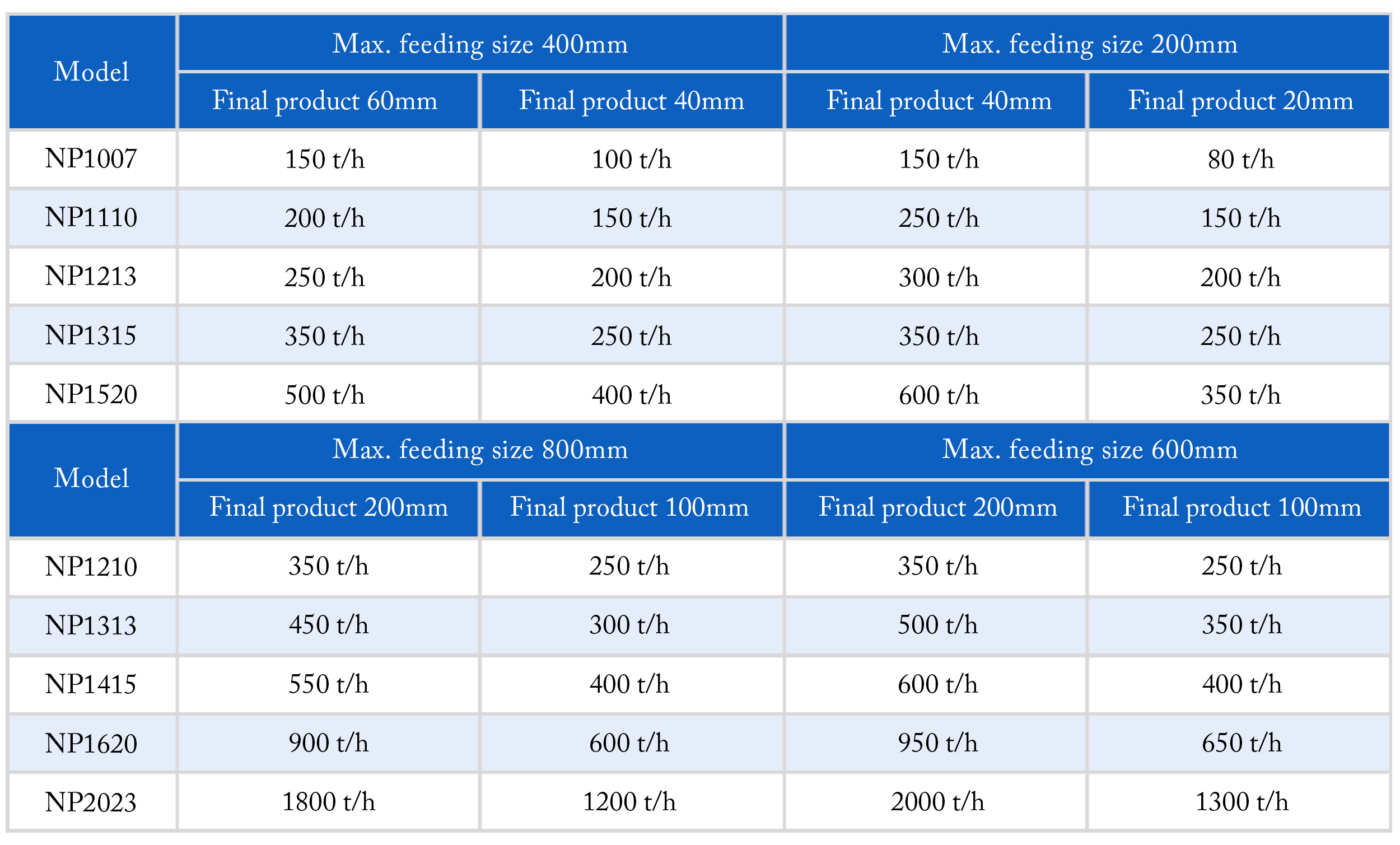

Crusher production capacity:

${currentPro.title}