EN

Language

All categories

Product ID: 68652300

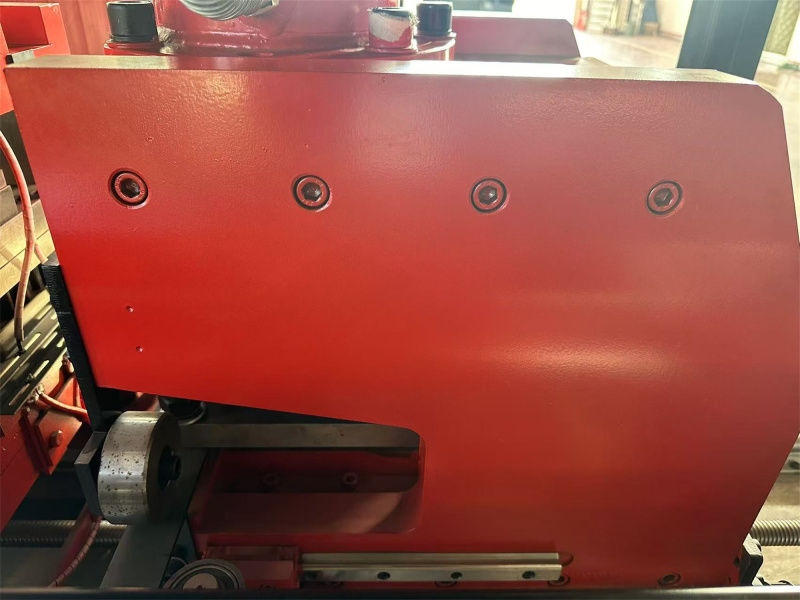

Advanced Cable Tray Punching Machine Technology

Contact Now

Description

1. The main machine base is fabricated from welded national standard 300/150-H type steel, with a 16mm thick steel plate on top. It is then machined using a gantry milling machine, ensuring flatness of the base while eliminating internal stress. The interior is coated with anti-rust paint to prevent rust and cracking in a humid environment.

2. The open-and-close die frame is precision machined from 45# steel plates through multiple processing steps, ensuring surface flatness and accuracy. It is assembled according to mold assembly procedures.

3. The punch and lower die plate of the stamping die are made from national standard Gr 12mov material, forged to high density, then vacuum heat treated, followed by wire cutting, and finally assembled. The die can switch freely between single and double row without the need to remove the mold externally.

2. The open-and-close die frame is precision machined from 45# steel plates through multiple processing steps, ensuring surface flatness and accuracy. It is assembled according to mold assembly procedures.

3. The punch and lower die plate of the stamping die are made from national standard Gr 12mov material, forged to high density, then vacuum heat treated, followed by wire cutting, and finally assembled. The die can switch freely between single and double row without the need to remove the mold externally.

4. The positioning guide sleeve is made from bearing steel, forged, and lathed, then vacuum heat-treated and precisely ground. It has high concentricity and strong wear resistance. Both sides of the adjustment base are synchronously adjustable with high precision and minimal deviation. The mold measurement positioning bar ensures that the mold size remains unchanged with each replacement, and the replacement can be completed within five minutes.

5. The conveyor shaft is made of 45# cylindrical steel, roughly machined on a lathe, and finely ground on an external cylindrical grinder to ensure concentricity and accurate positioning.

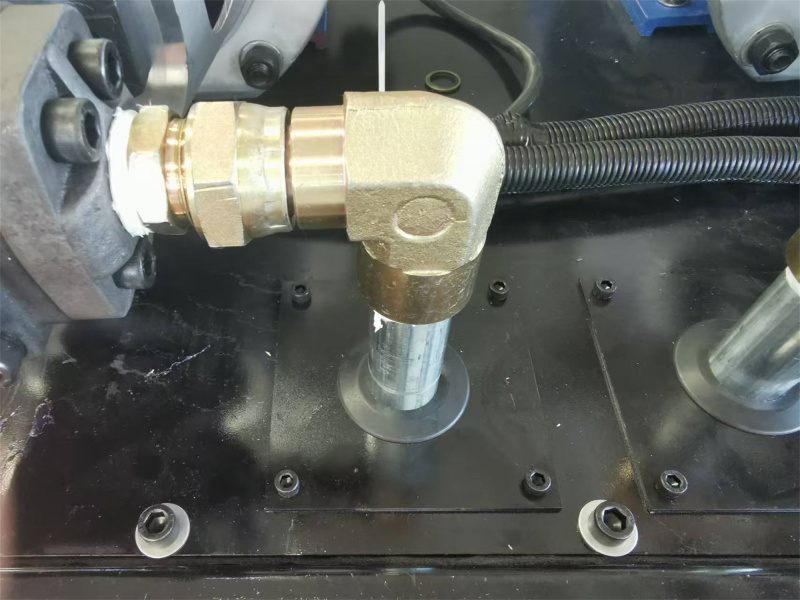

6. The hydraulic pump station system is developed and designed using Taiwanese technology. It uses a 7.5KW dual-motor independent oil pump, with additional dual-power air cooling. The external oil pipes are fitted with wear-resistant sleeves to prevent damage caused by fatigue wear, ensuring the stability and longevity of the hydraulic system. It has a beautiful appearance and requires zero floor space.

7. The hydraulic cylinder uses a specially designed high-pressure thick-walled cylinder, providing good sealing, high load capacity, low noise, and long service life.

8. The motor is a Taiwan joint-venture Shanghai RUIJIN brand reducer. The punching machine has a dedicated distribution box, custom-designed specifically for Yiping Machinery. The positioning guide sleeve is made from bearing steel, forged, lathed, vacuum heat-treated, and precisely ground. It has high concentricity and strong wear resistance. Both sides of the adjustment base are synchronously adjustable with high precision and minimal deviation. The mold measurement positioning bar ensures that the mold size remains unchanged with each replacement, and the replacement can be completed within five minutes.

5. The conveyor shaft is made of 45# cylindrical steel, roughly machined on a lathe, and finely ground on an external cylindrical grinder to ensure concentricity and accurate positioning.

6. The hydraulic pump station system is developed and designed using Taiwanese technology. It uses a 7.5KW dual-motor independent oil pump, with additional dual-power air cooling. The external oil pipes are fitted with wear-resistant sleeves to prevent damage caused by fatigue wear, ensuring the stability and longevity of the hydraulic system. It has a beautiful appearance and requires zero floor space.

7. The hydraulic cylinder uses a specially designed high-pressure thick-walled cylinder, providing good sealing, high load capacity, low noise, and long service life.

8. The motor is a Taiwan joint-venture Shanghai RUIJIN brand reducer. The punching machine has a dedicated distribution box, custom-designed specifically for Yiping Machinery. The positioning guide sleeve is made from bearing steel, forged, lathed, vacuum heat-treated, and precisely ground. It has high concentricity and strong wear resistance. Both sides of the adjustment base are synchronously adjustable with high precision and minimal deviation. The mold measurement positioning bar ensures that the mold size remains unchanged with each replacement, and the replacement can be completed within five minutes.

Contact Now

Please Send Message

${currentPro.title}