EN

Language

All categories

Product ID: 68654354

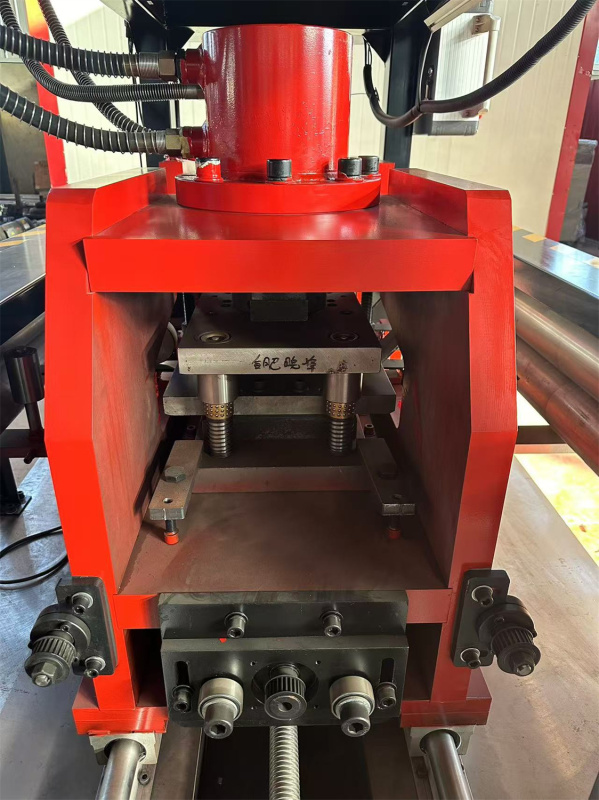

Precision Punching System for Metal Working

Contact Now

Description

<p>High Accuracy Punching Machine is a state-of-the-art solution designed for precision sheet metal punching applications. This advanced metal punching equipment ensures exceptional accuracy, reliability, and efficiency in manufacturing processes. Whether you are working with thin or thick materials, this machine delivers consistent results that meet the highest industry standards. Its robust construction and innovative design make it an essential tool for any industrial setting requiring high-quality punched components.</p><p>The overview of this precision sheet metal punching machine highlights its ability to handle a wide range of materials, including steel, aluminum, and other alloys. It is equipped with a high-precision punch system that allows for accurate hole placement and minimal material deformation. The machine's modular structure enables easy customization to suit specific production needs. With a user-friendly interface and automated controls, operators can efficiently manage the punching process without compromising on quality or safety.</p><p>Key features of this high accuracy punching machine include a sturdy frame that ensures stability during operation, a precise die set for accurate punching, and an adjustable speed control to accommodate different material thicknesses. The machine also offers a long service life due to its durable components and low maintenance requirements. Additionally, it is designed with safety in mind, featuring emergency stop functions and protective guards to prevent accidents. These characteristics make it ideal for both small-scale workshops and large manufacturing facilities.</p><p>The detailed description of this precision sheet metal punching equipment reveals its versatility and adaptability. It is suitable for a variety of industries, such as automotive, aerospace, electronics, and construction. The machine can be integrated into existing production lines or used as a standalone unit. Its compatibility with various tools and accessories further enhances its functionality. Moreover, the machine's energy-efficient motor reduces power consumption while maintaining optimal performance. This makes it an environmentally friendly choice for manufacturers looking to minimize their carbon footprint.</p><p>Use scenarios for this high accuracy punching machine are diverse and include tasks such as creating holes in panels, forming parts, and cutting complex shapes. It is particularly useful in applications where precision and consistency are critical, such as in the fabrication of electrical enclosures, mechanical components, and structural parts. The machine's ability to produce clean, accurate cuts without burrs or deformations ensures that the final products meet exact specifications. This level of precision helps reduce waste and rework, ultimately improving productivity and cost-efficiency.</p><p>User reviews of this metal punching equipment consistently highlight its reliability, ease of use, and high-quality output. Many users appreciate the machine's ability to maintain accuracy even after extended periods of use. Others mention the positive impact it has had on their workflow, allowing them to complete projects faster and with greater confidence. Some users have also praised the machine's durability and the support provided by the manufacturer. Overall, the feedback reflects a strong satisfaction level among customers who rely on this equipment for their daily operations.</p><p>Frequently asked questions about this precision sheet metal punching machine often revolve around its capabilities, maintenance, and compatibility. Users commonly inquire about the maximum thickness of materials it can handle, the types of dies available, and the ease of installation. Others ask about the warranty period, service options, and how to troubleshoot common issues. The manufacturer provides comprehensive documentation and support to address these concerns, ensuring that users can operate the machine effectively and safely. Regular maintenance is recommended to keep the machine in optimal condition, which includes cleaning, lubrication, and inspection of key components.</p>

Contact Now

Please Send Message

${currentPro.title}