Steel Structure Industry Automatic H Beam Production Line

Description

产品描述

H-beam Horizontal Production Line

H-beam Horizontal Production Line General introduction:

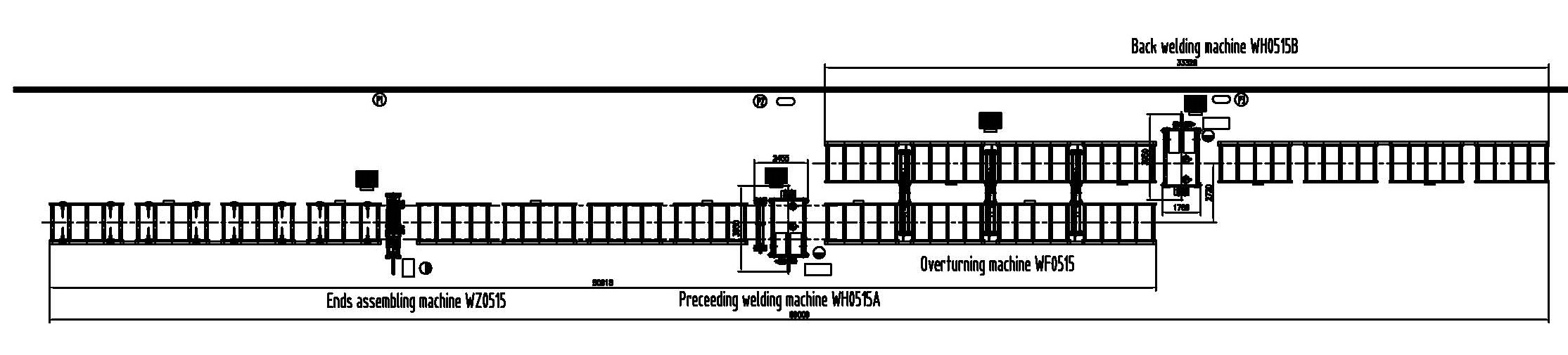

Horizontal type H-beam production line is a special welding line for assembling and welding H-beam. Compared with common H-beam vertical production line (first assembling to T type, then welding H-type), it has higher production efficiency and less welding deformation, and is especially suitable for light duty H-beam welding. This production line is composed by assembling machine, preceding welding machine, overturning machine, latter welding machine, and conveyor rollers, which can realize the jobs of H-beam assembling, welding, overturning, and conveying.

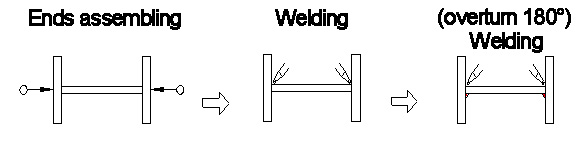

H-beam Horizontal Production Line Technical process drawing:

H-beam Horizontal Production Line Technical parameters:

|

Web Plate Height of H beam |

250-1500 mm |

|

Web Plate Thickness of H beam |

4-16 mm |

|

Flange Plate Width of H beam |

150-500 mm |

|

Flange Plate Thickness of H beam |

5-20 mm |

|

H-beam Length |

4000-15000 mm |

|

Max H beam Weight |

4000 kgs |

H-beam Horizontal Production Line Main technical features:

Traditional H-beam welding line (mainly using vertical assembling and fillet welding in the flat position) has big welding deformation and low production efficiency. It is not suitable for light duty H-beam welding, so we developed this horizontal type H-beam production line, which has following advantages:

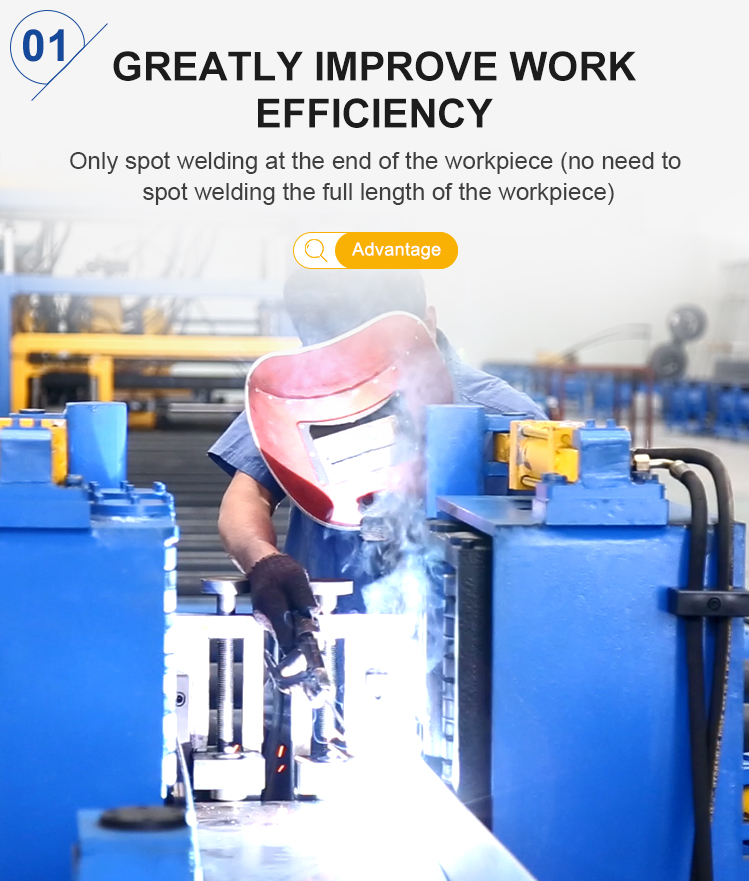

1. When assembly just need spot welding at the end (no need to weld all beam), then come to latter weld process. The machine will position and welding another three free plates, so this will improve the assembly efficiency a lot.

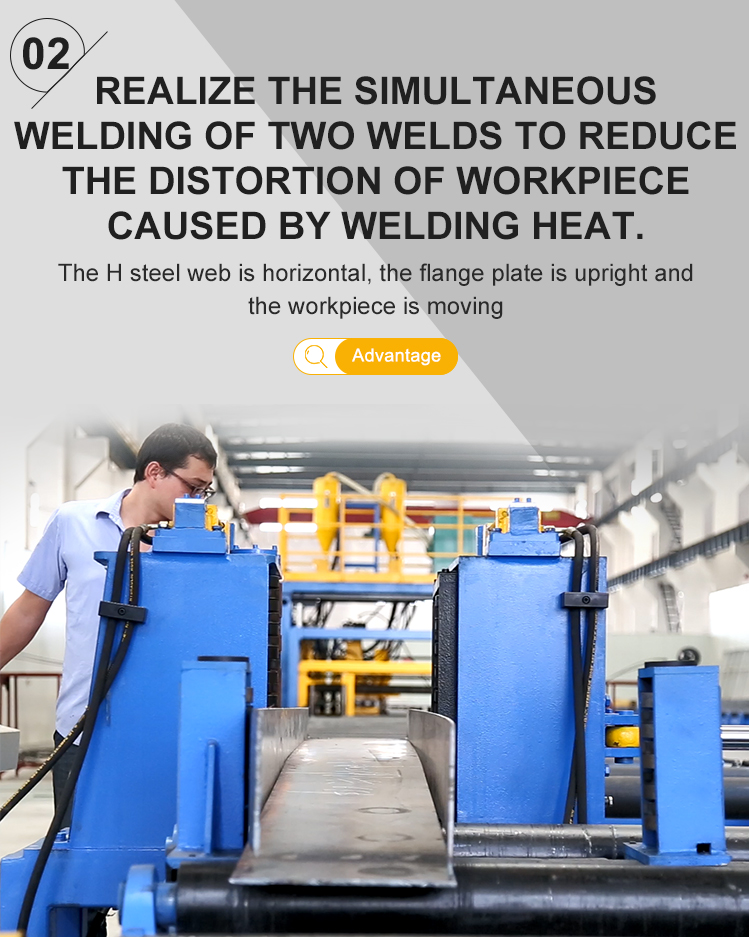

2. The beam put in horizontal position (web plate in horizontal position and flange plate in vertical position), moving the workpiece while welding. This welding way can realized two seams simultaneously welding, which reduced deformation after welding.

3. The welding power source is American Lincoln DC-1000. It is single arc and double wires .The wire diameter is Φ1.6mm, welding speed is 1.2m/min,so the seam’s quality will be very good and has nice appearance .

H-beam Horizontal Production Line Layout drawing:

H-beam Horizontal Production Line Details:

When assembly, just needed to do spot welding of H beam end, after positioned ,then can go into the welding process, welding machine will re-position the three plate, thus increase assemble speed.

${currentPro.title}