Steel Beam Assembly Welding Straightening Machine

Description

Product description

Parameter

H-beam vertical assembling, welding and straightening multi-function integrated machine is a high-efficiency equipment for the production of welded H-beams. It can simultaneously complete H-beam assembly, submerged arc welding, and flange plate welding deformation on the same machine.The machine occupies a small area which can save installation space. It saves the hoisting and turning time between each process with single machine,then the efficiency is greatly improved, and the cost is reduced. It is a high-tech, economical and practical H-beam production equipment.

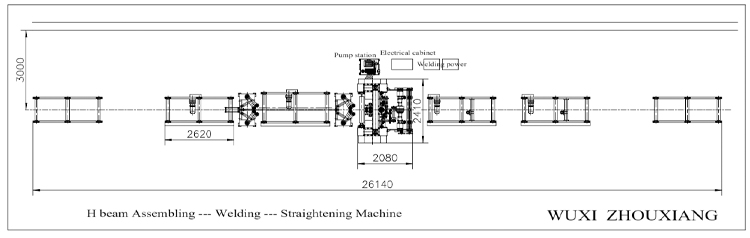

H beam assembling, welding, straightening machine

Metric units:

| Web plate height | 200~1500 mm |

| Web plate thickness | 6~14 mm |

| Flange plate width | 200~800 mm |

| Flange plate thickness | 6~20 mm |

| H beam length | 6000~15000 mm or as user’s request |

| Assembly and welding speed | 0.35~3 m/min |

| Main machine power | 4 KW |

| Roller conveyor motor power | 4 x 0.55 Kw=2.2 kW |

| Flux recycling machine motor power | 2 x 3 kw=6 kW |

| Pump station power | 4 kW |

| Welding source power | 2 x 69 kW=138 kW (Lincoln DC-1000) |

|

Above are our standard model, it can be designed and manufactured according to customer’s request. |

|

H beam Assembling Welding and Straightening Machine Details:

1) Two sets welding gun weld the welding seam of H-beam at the same time.

${currentPro.title}